5

GENERAL INFORMATION

1.3 Description of the appliance

The condensing thermal unit TAU Unit is a hot water generator,

with high thermal efciency, for the heating of environments

and production of domestic hot water (DHW) coupled to an ex-

ternal heater.

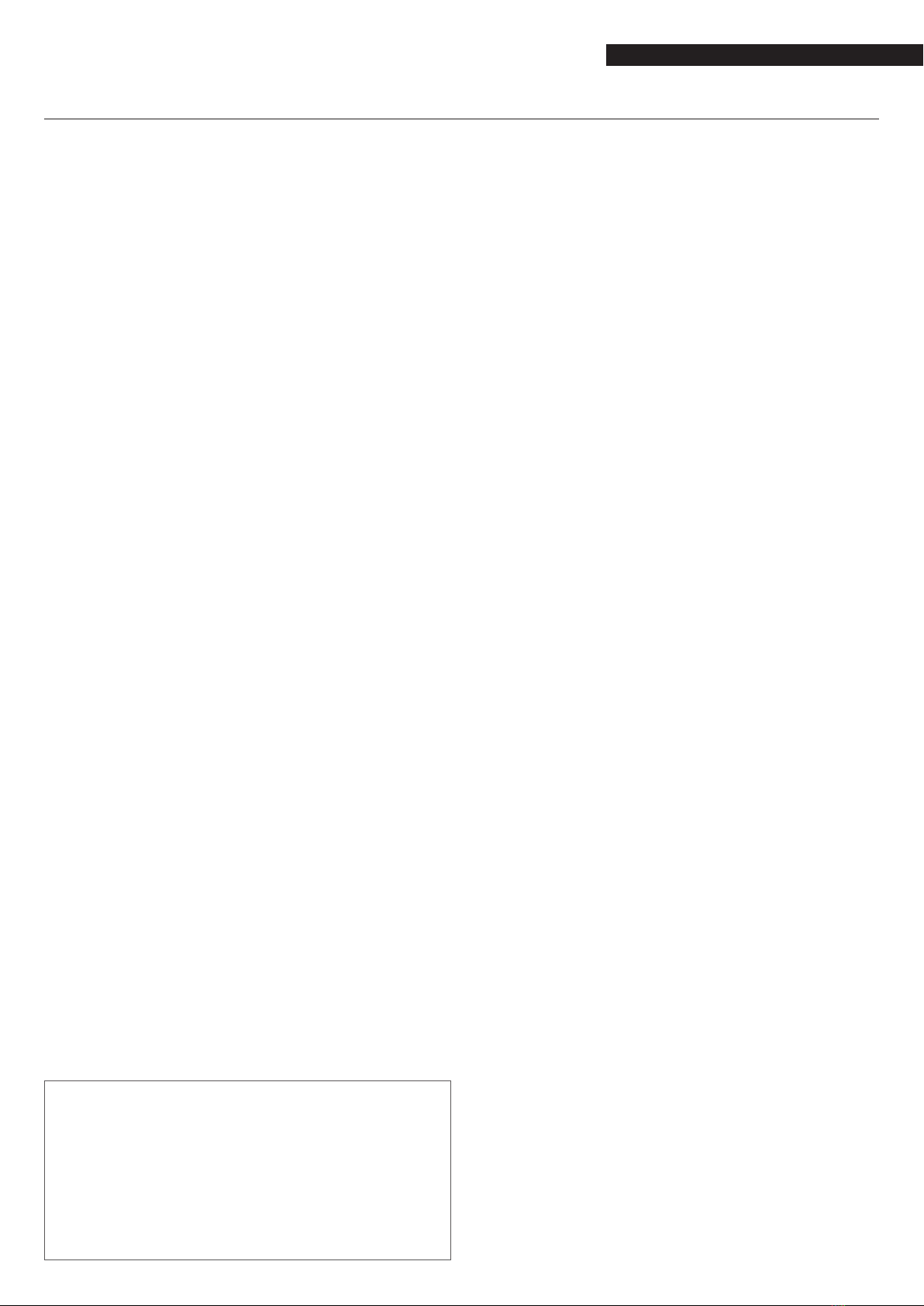

The boiler body is in high alloy stainless steel and develops ver-

tically ensuring maximum duration and reliability, meeting at

the same time the most stringent national and European reg-

ulations on the emission of heavy metals in condensate drain

waters.

The double return hydraulic circuit (high or low temperature) fa-

vours temperature stratication inside the body and optimises

the performance.

The boiler body is covered in high density glass wool insulation

to reduce heat loss.

The pre-mixed microame burner with power modulation ratio

1:10 ensures low polluting emissions (NOx and CO) in compliance

with the most stringent European Regulations.

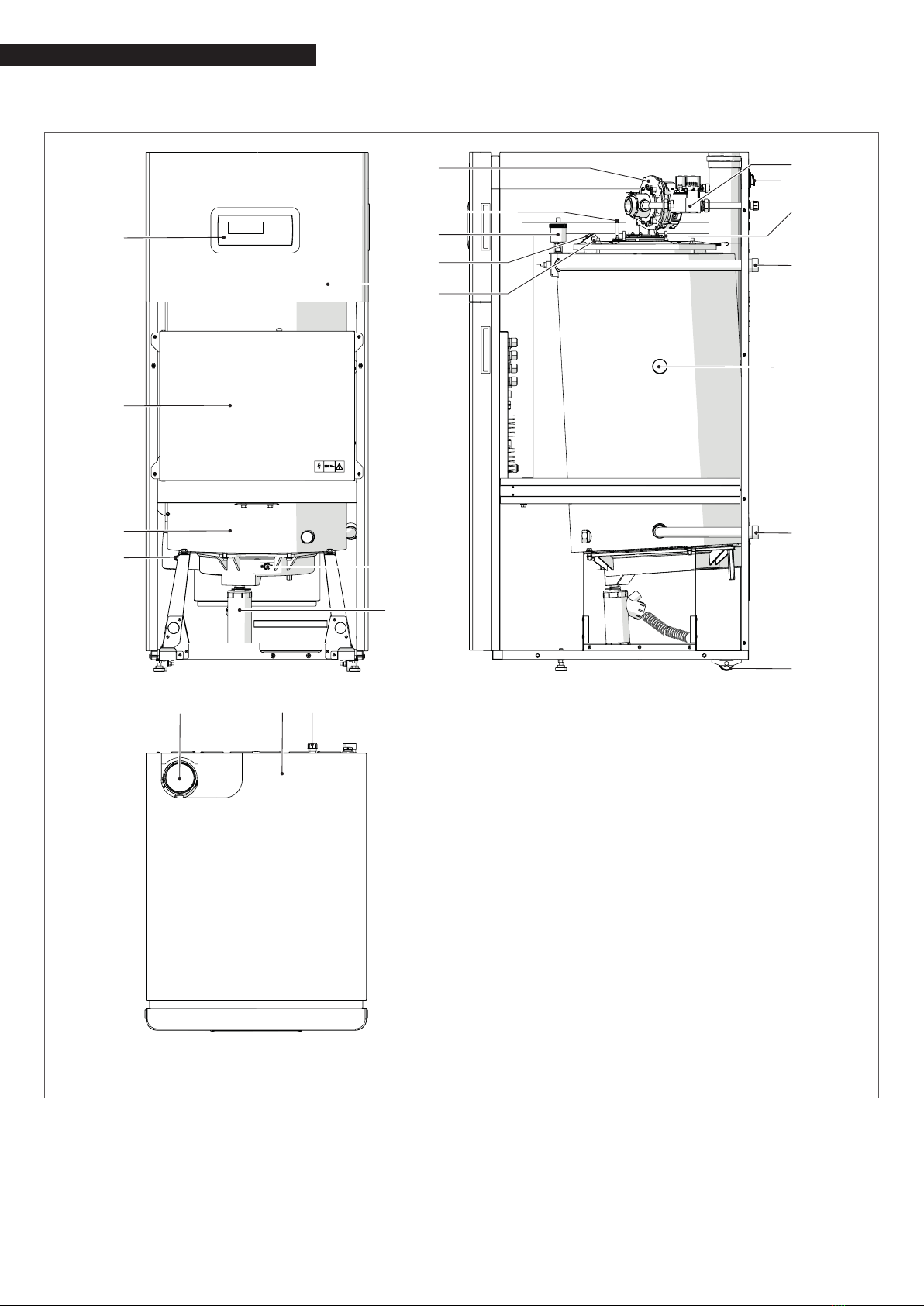

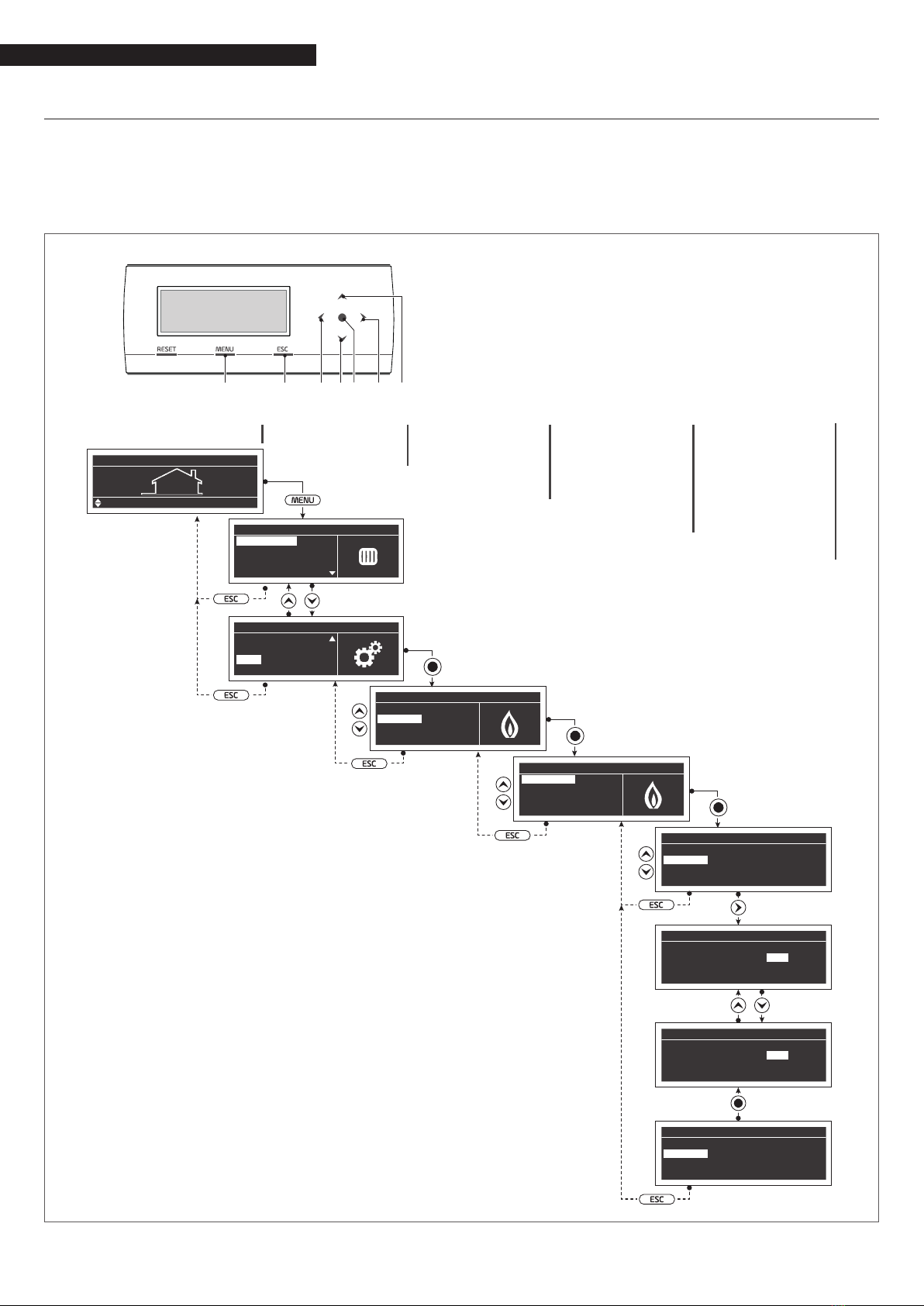

The thermoregulation with user interface and display in the

control panel TAU Unit allows managing the safety and control

devices in compliance with current regulation. By connecting

the external probe it is possible to activate the climatic control

function of the heating circuit, enhancing the seasonal energy

recovery characteristics.

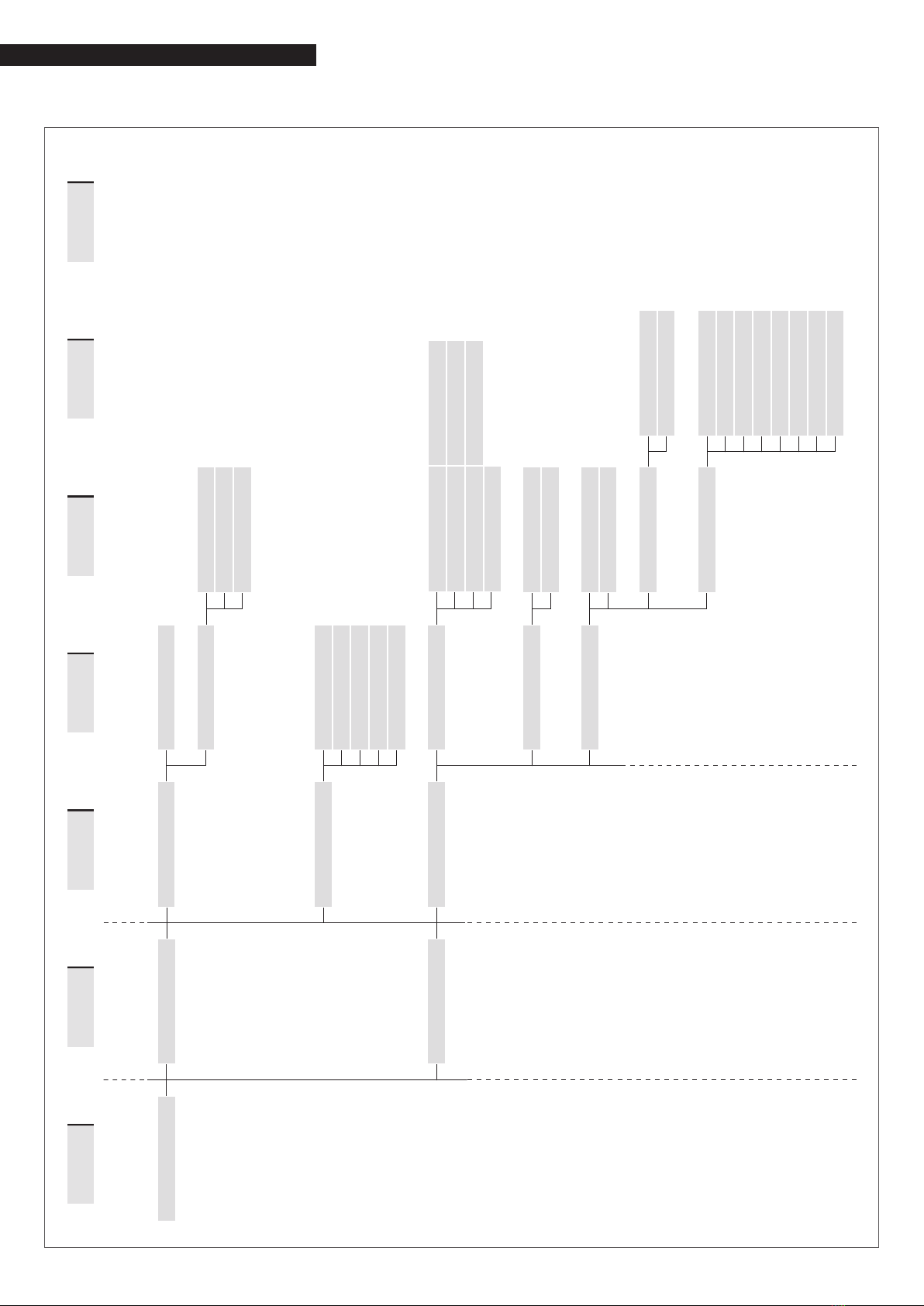

The thermoregulation adapts with exibility to the different sys-

tem needs; for example, it is possible to increase the number

of heating circuits supplied with high and low temperature and

connect the devices TAU Unit in cascade (see accessories Cata-

logue).

1.4 Safety and control devices

The thermal unit TAU Unit is equipped with the most advanced

safety and regulation systems available on the market.

Each fault is signalled through a numeric error code displayed

on the screen and stops the equipment causing the automatic

closure of the gas valve.

The following are installed on the water circuit:

−Safety thermostat: on the body of the generator, it inter-

venes to stop the appliance if the temperature exceeds

the threshold limit of 110°C.

−Delivery temperature probe: immersion probe on the

delivery line of the generator is used by the regulator

to view and check the delivery water temperature and

check the correct switching on and off of the equipment

based on the programmed setpoint. The regulator uses

the same probe to stop the generator in case of overtem-

perature, before the triggering of the safety thermostat.

−Return temperature probe: the contact probe placed

on the return line of the boiler is used by the regula-

tor to view the return water temperature with which it

calculates, together with the delivery temperature, the

temperature difference between delivery and return (∆t),

which allows regulating the modulation of the thermal

unit circulation pump in heating mode.

−Flue gas thermostat: placed in the lower part of the

exchanger, it triggers with high ue gas temperature

(>75°C).

−Flue gas probe: placed in the lower part of the exchang-

er, causes a temporary error if the temperature of the

combustion products exceeds 85°C, and a permanent

error if it exceeds 90°C.

Through specic inlets and outlets, the thermoregulation TAU

Unit allows managing the following optional safety devices out-

side the equipment:

−Pressure transducer or water minimum pressure switch:

the connection of one of the two optional devices, to be

carried out by the installer, allows the thermoregulation

to continuously view and check the pressure of the pri-

mary circuit to start or stop the equipment in case of low

pressure.

−LPG fuel shut-off solenoid valve: the thermoregulation,

via a programmable output, allows managing (based on

the designated type of fuel and system) the fuel shut-off

solenoid valve for LPG, installed outside the equipment

by the installer.

−Gas minimum pressure switch: a specic outlet is pres-

ent for the connection of the gas minimum pressure

switch (optional) to be installed outside the equipment.

The device will continuously check the correct inlet gas

pressure to start or stop the equipment in case of low

pressure.

9 The triggering of the safety devices indicates a potentially

dangerous malfunctioning of the equipment. Therefore,

immediately contact the Technical Assistance Service.

9 Safety devices must be replaced by Technical Assistance

Service, using only original parts. Refer to the spare parts

catalogue supplied with the appliance. After the repair per-

form an ignition test and check that the equipment works

correctly.

0 The appliance must not be put in service, even temporarily,

when tampered safety devices are not in operation or have

been tampered with.