Rigel SafeTest 50 Instruction Manual –Revision 1.0 6

1 Introduction

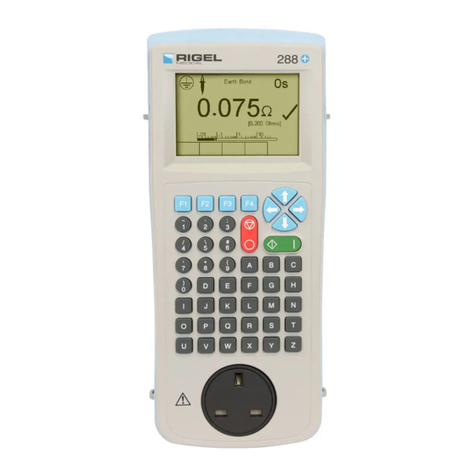

The Rigel SafeTest 50 is a dedicated medical safety analyzer, ideal for testing high volumes of basic

medical and laboratory equipment. A robust and reliable design ensures that the SafeTest 50 can

withstand a busy schedule of testing medical equipment that does not require patient lead testing,

such as beds, hoists, infusion pumps, CPAP’s, centrifuges, etc.

With a large color display and a color coded user interface, it’s easy to select the required tests with

a single key press, while a fast step-through of the test routine makes the testing process speedy

and dependable. Though physically small, the SafeTest 50 includes a range of safety tests to

enable compliance with a range of international safety standards, including leakage testing to NFPA-

99, AAMI ES 60601, IEC 62353 and 61010, ground bond testing to NFPA-99, IEC 62353 and 61010

(Annex F).

Full manual control offers the benefit of executing only those specific tests that are required and

provide the user with full control of the power cycles, making testing simple, easy and fast. An

automatic warning of secondary ground paths ensures users are made aware when invalid readings

are made, thus ensuring correct and accurate test results first time, every time.

1.1 Key Features

Compact, robust and portable design

Fast step-through of test routines with minimized power breaks

Manual control of fault conditions

Tests to a range of international standards including NFPA-99, AAMI ES 60601, IEC 62353

and 61010

Large, highly visible color display.

Secondary ground warnings to ensure valid test setup

Accurate high current, low energy ground bond testing

Supplied with free, protective carry case

Multi-voltage - operates on any mains supply between 90-264V / 48-64Hz

1.2 Rigel SafeTest 50 includes: