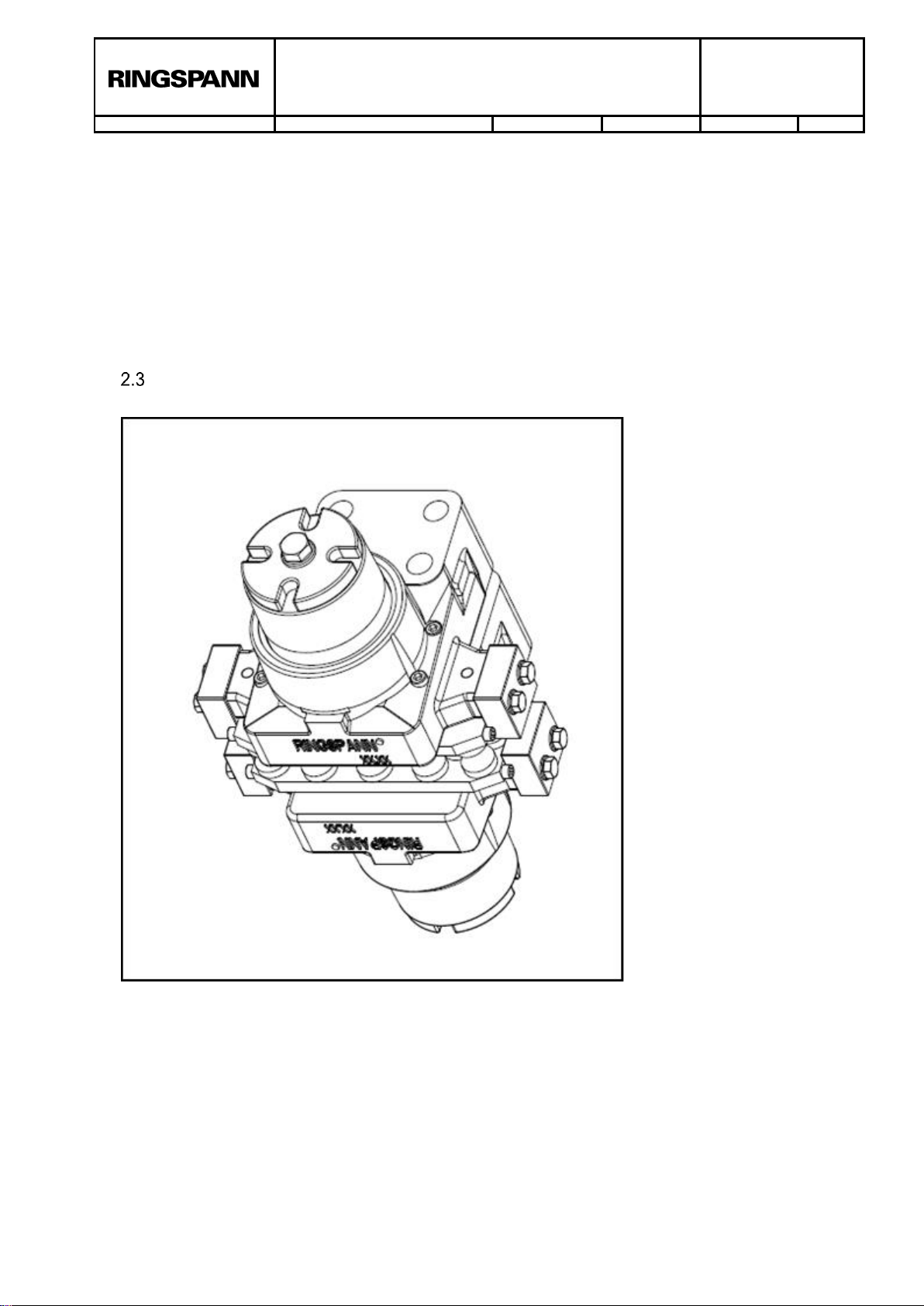

Installation and Operating Instructions

for Brake Caliper HW 075 FHM

spring activated –hydraulic released

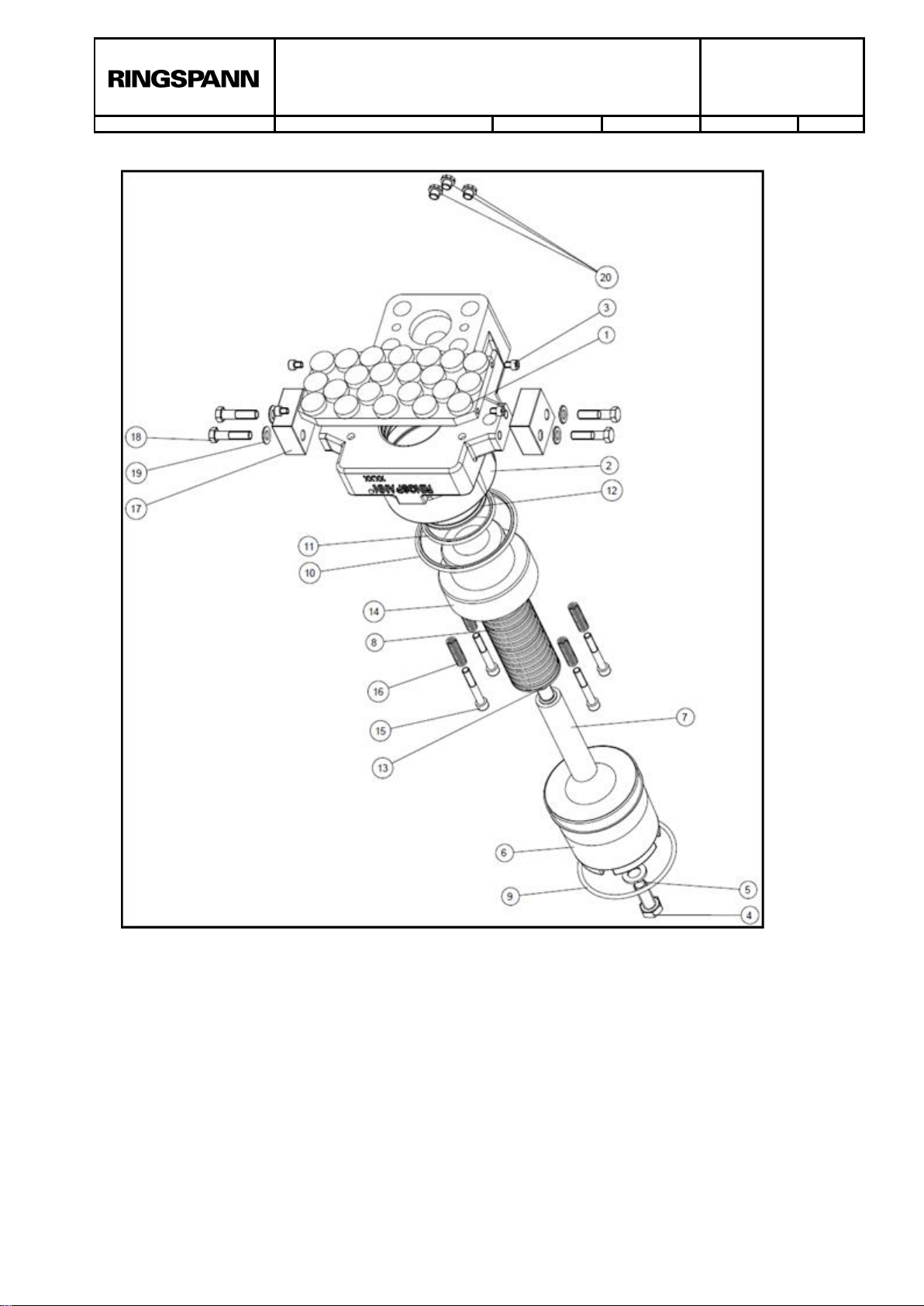

8. Installation the RINGSPANN brake

General instructions for assembly and installation

Before installing the brake, the brake disc must be cleaned with alcohol (e.g. spirit (ethanol) or

isopropyl alcohol) or with water-based tenside solutions (soapy water or the like.

If cleaning the brake disc with a diluent, acetone or brake cleaning agent, it must be ensured that

these agents and no residues of these agents come into direct contact with the friction pads. This

must be ensured for pure holding brakes in particular, since no dynamic braking takes place that

would remove any diluent residues from the brake disc.

Caution!

Residues from oil and anti-rust agent considerably reduce the coefficient of

friction and therefore also the braking and holding torque!

Assembly and installation

Caution!

The brake caliper must not be exposed to hydraulic pressure during assembly/

installation. If hydraulic pressure escapes during assembly, the brake can

suddenly close!

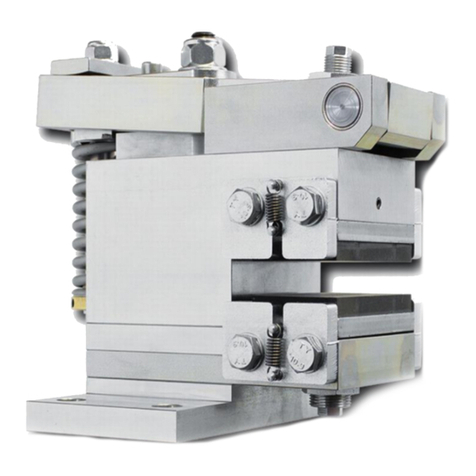

The standard brake calliper is fastened to the machine part with 4 srews M24-10.9 tightening

torque 1017 Nm. Tightening torque calculated with μG = 0.12 as the average coefficient of

friction in the thread and μK = 0.12 as the coefficient of friction in the head support according to

VDI 2230 Page 1 of Feb. 2003.

(The screws are not included in the delivery).

The thickness of the customer’s connection plate between the two halves of the brake caliper

must correspond exactly to the thickness of the brake disc + 3 mm. This provides for a distance

of 1.5 mm between the brake disc and the brake pad on each side.

In order to ensure sufficient space for brake pad changes, a gap of at least 260 mm should be left

on one side, so that the brake pads can be removed and installed easily.

Before assembly it is to be checked whether the the customer connection part is even and the

concentricity between the brake disc and mounting surface is within a tolerance of 0.3 mm.

Examine the axial movement of the brake disc. The axial movement must not be greater than ±

0.3 mm.

The maximum permissible axial run-out of the brake disc is 0.1 mm; a greater axial run-out can

lead to the brake unit rattling and shaking.