Front Panel Removal

The front panel is held in position by four screws, one at either end of the

top louvre and at either end of the underside of the base panel. After

removing all screws ease the panel straight forward clear of the heater.

TF Model Only

An earthed power point is required within 1.5m from the heater.

TESTING PROCEDURE

After clearing .a11swarf and purging the gas supply to the heater, connect

the gas and check for leakage at connections.

Check Burner Pressure

Turn knob to ignition position to light burner. If burner fails to light,

repeat. The heater is fitted with a flame failure valve included in the gas

valve. Hold valve in the ignition position for 20 seconds and then release.

The heater should continue to operate. If burner goes out check position

of thermocouple in flame and repeat ignition procedure.

Turn control to “Off” position. Remove test point screw and attach

manometer. Light unit in usual way. Leave full on and check pressure.

Reset pressure by adjusting regulator screw if necessary. Regulator is

situated on the side of the gas cock assembly. Check the supply pressure

before making adjustments to unit as the regulator has been factory preset.

Turn control to “Off” position before removing manometer. Replace the

test point screw. Pilot gas rate cannot be adjusted. Turn heater on and off

again a few times to check ignition.

Fan - TF models only

Connect power lead to wall socket and switch on power. Move heater fan

switch to on position and check operation of fan.

Fault Failure Procedure

If you cannot get the heater to work properly, contact Rinnai NZ Ltd, their

nearest Service Centre or Gas Utility.

INSTRUCT CUSTOMER IN USE AND CARE OF THE HEATER

Make sure the customer understands the instructions.

*

3.

4.

SERVICING INSTRUCTIONS

Rinnai recommend your Cosypanel heater is serviced every year.

1. Multifunctional Gas Valve incornoratincr oiezo ianition,

regulator and flame failure safetv device

This valve is designed as a sealed unit and as such it should not be

? $s.isnan;~d except to replace the flame failure safety device magnetic

2. Thermocounle

The thermocouple may be replaced b

t: removin

from it’s mounting bracket above the %the thermocouple

urner an releasinq the

connector from the gas valve.

Burner and Injector

Remove the mounting screw from the left hand end of the burner and

slide burner sideways clear of the injector. The injector may now be

unscrewed if required.

Gas Valve

Turn off

from walP

as supply and disconnect from heater. Remove the heater

and remove screws from the valve mounting bracket, two

from rear panel and one from burner chamber.

Release thermocouple, pilot tube, gas supply pipe and piezo ignition

lead. Lift the valve clear of the heater.

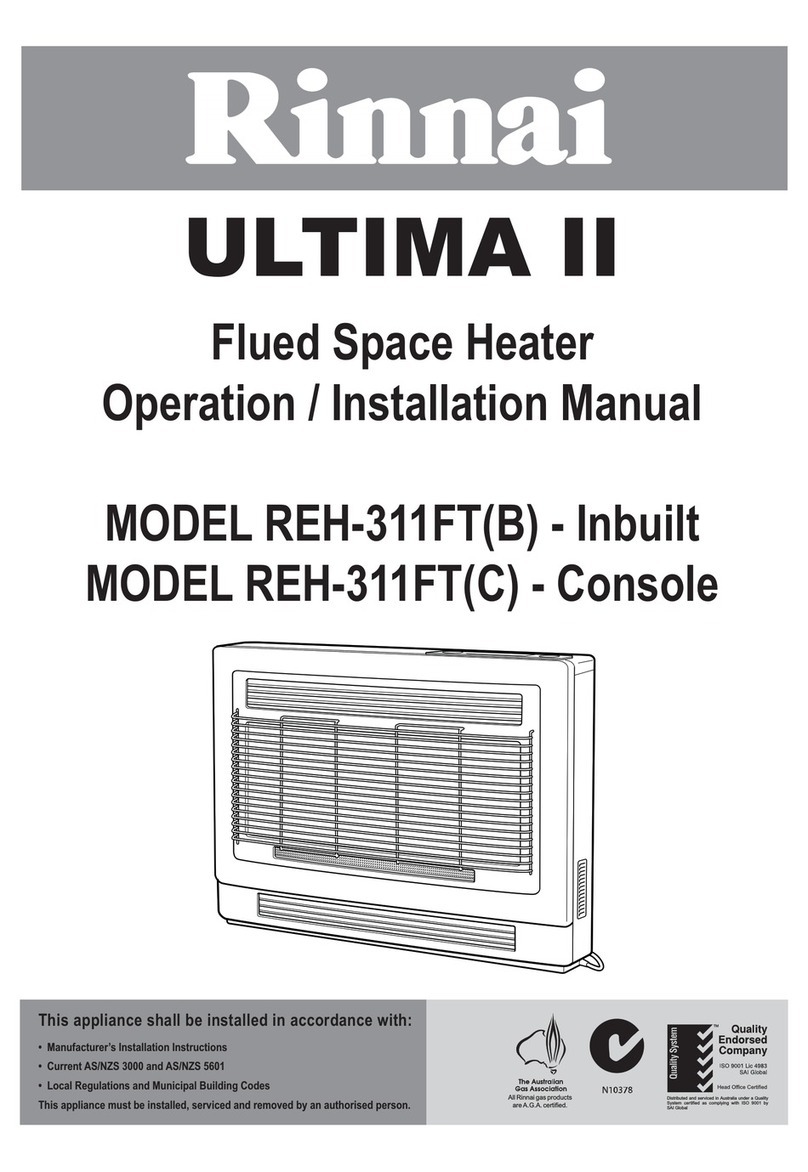

Description SPECIFICATIONS

-

- Rinnai Cosypanel R800 / 501T convector wall

heater

Type -

Description -

Type -

Input -

Gas Control -

Burner

Test Point Pressure -

Gas Inlet

Ignition -

Injectors and Gas Rate -

Dimensions -

Electric Supply -

Fan -

6 7

Natural convection

Rinnai Cosypanel R800 / 501TF convector wall

heater with fan

Natural or forced convection

R800 NG 8.0 MJ/h R501 NG 5.3 MJ/h

Rinnai multi-functional one touch gas valve

Aeromatic single entry

NG only 1.0 kPa.

Flare fitting to suit 1Omm O.D. copper pipe

Piezo electric

Please see data plate LH side of front panel

Width 540mm, height 390mm, depth 128mm

over mounting bracket

(TF only) 230~ 50Hz A.C. only 0.06 AMP

(TF only) Royal 40mm single speed