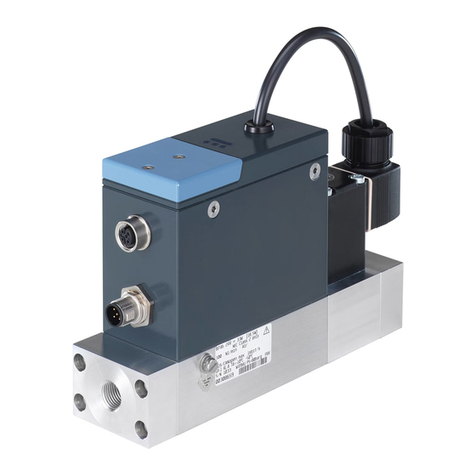

Type 8743

Table of contents

3

TABLE OF CONTENTS

1 About this document..................................................................................................................................6

1.1 Manufacturer .................................................................................................................................... 6

1.2 Used symbols................................................................................................................................... 6

1.3 Terms and abbreviations .................................................................................................................. 7

2 Safety instructions......................................................................................................................................8

2.1 Intended use..................................................................................................................................... 8

2.2 Safety................................................................................................................................................ 8

3 Product description..................................................................................................................................11

3.1 Product overview............................................................................................................................ 11

3.2 Product identification ..................................................................................................................... 13

3.2.1 Type label...........................................................................................................................13

3.2.2 Calibration label .................................................................................................................14

3.2.3 Conformity marking ...........................................................................................................14

3.2.4 Symbols and markings on device......................................................................................14

3.3 Display elements ............................................................................................................................ 14

3.3.1 Status indicator..................................................................................................................14

3.3.2 NAMUR mode....................................................................................................................15

3.3.3 Network status indicator....................................................................................................16

3.3.4 Communication indicator...................................................................................................16

3.4 Functionality ................................................................................................................................... 16

3.4.1 büS interface......................................................................................................................16

3.4.2 Actuator is a control valve .................................................................................................17

3.4.3 Memory card......................................................................................................................17

4 Technical data ..........................................................................................................................................18

4.1 Standards and Directives ............................................................................................................... 18

4.2 Operating conditions ...................................................................................................................... 18

4.3 Medium........................................................................................................................................... 18

4.3.1 Quality of the medium........................................................................................................19

4.3.2 Pressure loss .....................................................................................................................20

4.4 Electrical data ................................................................................................................................. 21

4.5 Communication .............................................................................................................................. 23

4.6 Mechanical data ............................................................................................................................. 23

5 Medium connection..................................................................................................................................24

5.1 Possible medium connections ....................................................................................................... 24

5.2 Installation procedure ..................................................................................................................... 24

5.2.1 G-internal-threaded connections.......................................................................................24

5.2.2 NPT-internal-threaded connections ..................................................................................26

5.2.3 Flange connections............................................................................................................26

6 Electrical connection................................................................................................................................28

6.1 Additional documentation .............................................................................................................. 28

6.2 Wire the variant Analogue with D-sub DE-9 male connector......................................................... 28

6.2.1 Digital input ........................................................................................................................29