10 - GR1-TM

GR1-TMEnglish

8

MAINTENANCE AND OPERATION MANUAL FOR GR1 GATE

FEEDBACK SIGNALS INFORMING ABOUT ROTOR’S MOVEMENT (PERSONAL PASSAGE)

Feedback signals inputs of NC type (Normal closed)

Feedback signals inputs of No type (Normal opened)

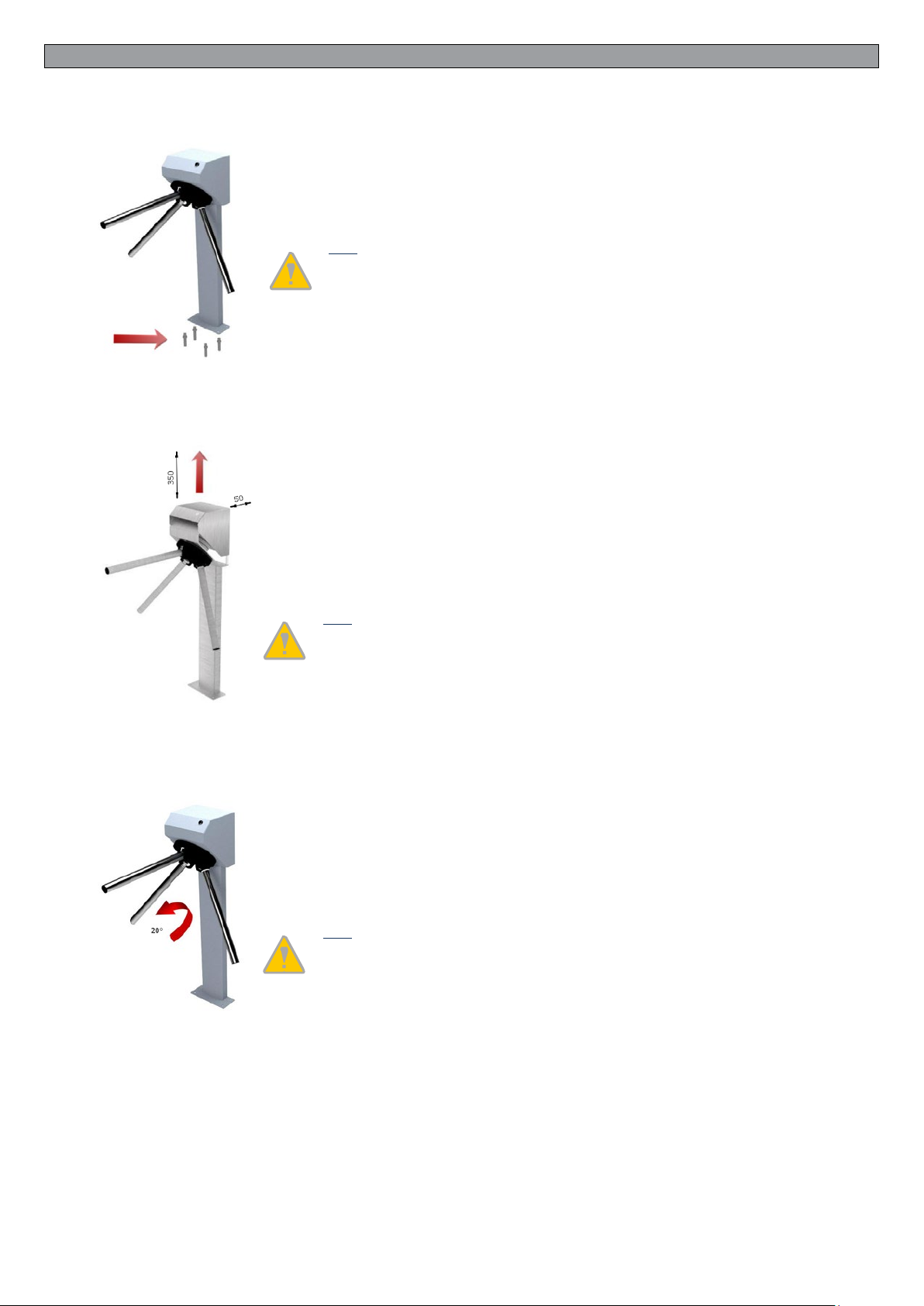

Feedback signals description in a graph

form

Feedback signal informs about making a rotation by the

rotor, that confirms correct personal passing through the

passage section. Feedback signal shall be used in systems,

where efficient and accurate pedestrian traffic control is

important.

Correct application of the signal

to release from external devices

(e.g. reader /control logic) is

possible only after obtaining a

feedback signal informing about

the rotation cycle completion

(personal passage).

Table below provides descriptions of feedback signals

outputs informing about rotor’s movement.

Table below provides a description of an output signals

graph, so called feedback:

OUT 1

PIN 11 - Feedback OUT1 (NO contact, I max = 0.5A

PIN 12 – Feedback OUT1 (COM contact, I max = 0.5A)

PIN 13 – Feedback OUT1 (NC contact, I max = 0.5A)

OUT 2

PIN 14 - Feedback OUT2 (NO contact, I max = 0.5A)

PIN 15 – Feedback OUT2 (COM contact, I max = 0.5A)

PIN 16 – Feedback OUT2 (NC contact, I max = 0.5A)

T1 Time between completion of the passage

cycle and application of the next pulse

T2,T4 A release signal S_11 or S_12 detecting time

T3 A release signal maintaining time (NOTE :

0,01 s ≤ T2+T3+T4 ≤ 1s)

T5 Pushing one of the rotor’s arms (sphere)

awaiting time (max 15s)

T6 Passage time (max. 15 s)

T7,T9 Time of switching one of transmitters at

outputs OUT1, OUT2 (min. 100 ms)

T8 The feedback signal lasting time (0.8 s)