Alvarado SLT Instructions for use

Other Alvarado Turnstile manuals

Alvarado

Alvarado TAS12-AS1 User manual

Alvarado

Alvarado Supervisor 500 User manual

Alvarado

Alvarado SLT Instructions for use

Alvarado

Alvarado MST Instructions for use

Alvarado

Alvarado Supervisor 3500 User manual

Alvarado

Alvarado SW1000 Owner's manual

Alvarado

Alvarado TAS12-EDM User manual

Alvarado

Alvarado UltraQ-AMT User manual

Alvarado

Alvarado SUPERVISOR 3000 User manual

Alvarado

Alvarado SUPERVISOR 3000 User manual

Alvarado

Alvarado EDM User manual

Alvarado

Alvarado UltraQ User manual

Alvarado

Alvarado SU5000 User manual

Alvarado

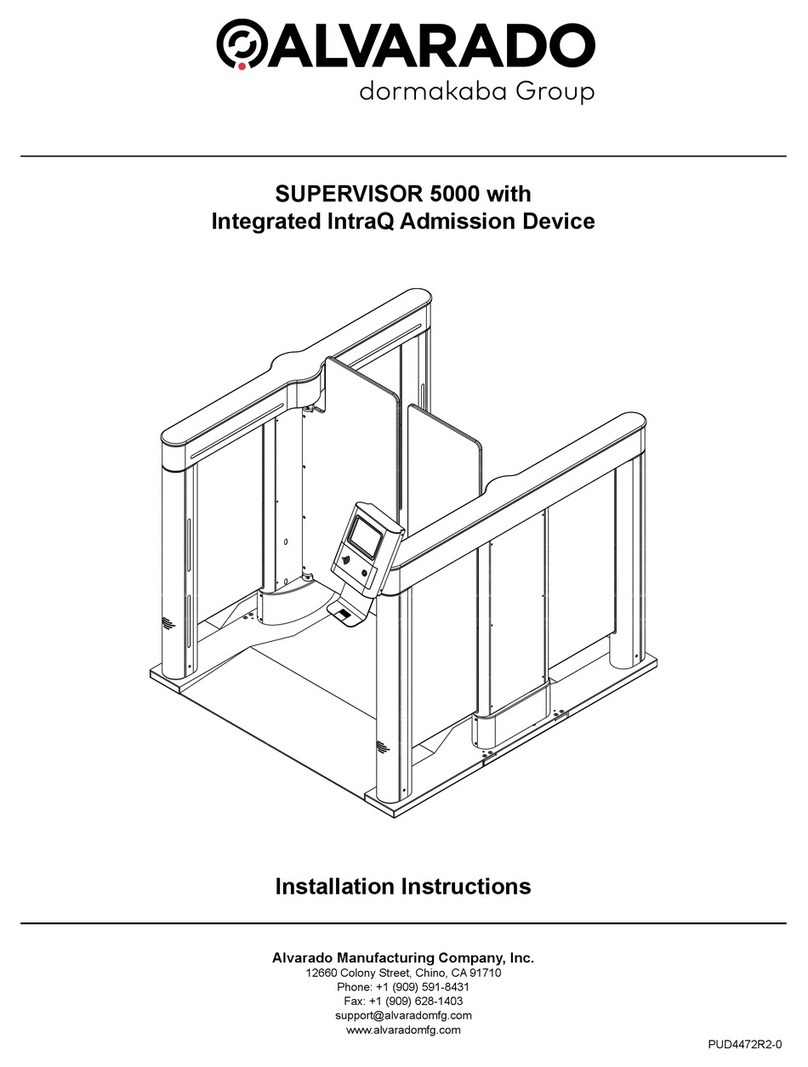

Alvarado SUPERVISOR 5000 User manual

Alvarado

Alvarado MT Installation and operating instructions

Alvarado

Alvarado EDC User manual

Alvarado

Alvarado MST-3 User manual

Alvarado

Alvarado UltraQ User manual

Alvarado

Alvarado MSTT-3 Service manual

Alvarado

Alvarado Supervisor 2000 User manual

Popular Turnstile manuals by other brands

DSI

DSI DST-80 Service & installation manual

OZAK

OZAK VP-125 Assembly, Installation and Maintenance Handbook

Automatic Systems

Automatic Systems SMARTLANE SL 90X Technical manual

JKDC SECURITY

JKDC SECURITY JKDC-100C user manual

Magnetic Autocontrol

Magnetic Autocontrol MPT 33 operating instructions

Oxgard

Oxgard Praktika T-04K Operational manual