2Pub. No. 1243 — April 2008

RITE-HITE®STR-4100 DOK-LOK®Installation Manual

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SAFETY WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SPECIAL APPLICATION INSTALLATION ITEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . BACK COVER

TABLE OF CONTENTS

INTRODUCTION

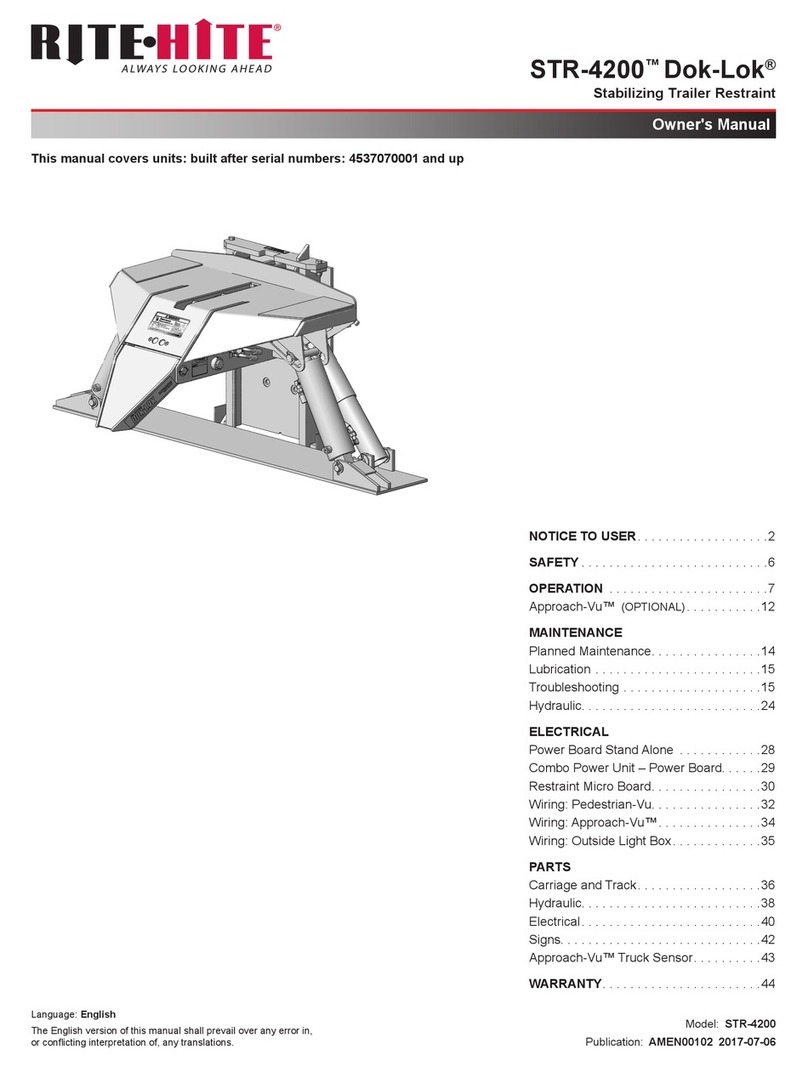

Read and understand this manual before attempting to install or operate any DOK-LOK vehicle restraint. For best

results, have this product serviced by your authorized RITE-HITE representative. The STR-4100 DOK-LOK vehicle

restraint by RITE-HITE is intended to provide a safer workplace for workers in shipping and receiving dock areas. The

STR-4100 DOK-LOK vehicle restraint is a hydraulic restraint device that, when properly installed and operated, retains

a secure connection between the truck and dock. Signal lights and signs provide instructions to the truck driver and

DOK-LOK vehicle restraint operator that a safe condition exists. The DOK-LOK vehicle restraint is operated by

pressing push buttons on an inside control panel.

NOTICE TO USER

Your local RITE-HITE®representative provides a Planned Maintenance Program (P.M.P.) which can be fitted to your

specific operation. Call your local representative or the RITE-HITE®Corporation at 414-355-2600.

The RITE-HITE®products in this manual are covered by one or more of the following U.S. patents: 4,865,507;

4,920,598; 4,995,130; 5,040,258; 5,271,183; 5,323,503; 5,375,965; 5,440,772; 5,442,825; 5,531,557; 5,546,623;

5,553,987; 5,582,498; 5,664,930; 5,702,223; 5,762,459 (RE: 37,570); 5,882,167; 5,964,572; 6,010,297; 6,052,268;

6,065,172; 6,070,283; 6,074,157; 6,085,375; 6,092,970; 6,106,212; 6,116,839; 6,190,109; 6,220,809; 6,627,016;

6,238,163; 6,311,352; 6,318,947; 6,322,310; 6,360,394; 6,368,043; 6,431,819; 6,488,464; 6,497,076; 6,499,169;

6,505,713; 6,524,053; 6,634,049; 6,654,976; 6,676,360; 6,726,432; 6,773,221; 6,832,403; 6,880,301; 7,032,267;

7,062,814; 7,134,159; 7,213,285; 7,216,391 and pending U.S and foreign patent applications.

RITE-HITE®, LEVEL-RITE®, THINMANTM, SAFE-T-LIP®, HYDRACHEK®, WHEEL-LOKTM, DOK-LOK®, DUAL-DOK®,

SAFE-T-STRUTTM, DOK-COMMANDER®, JUMBOTM, HYDRA-RITETM, SAFE-T-GATE®, and SMOOTH TRANSITION

DOK SYSTEMTM, are trademarks of RITE-HITE®Corporation.