Rite-Hite®Owner's Manual STR-4200™ Dok-Lok®

Publication: AMEN00102 2017-07-06 9

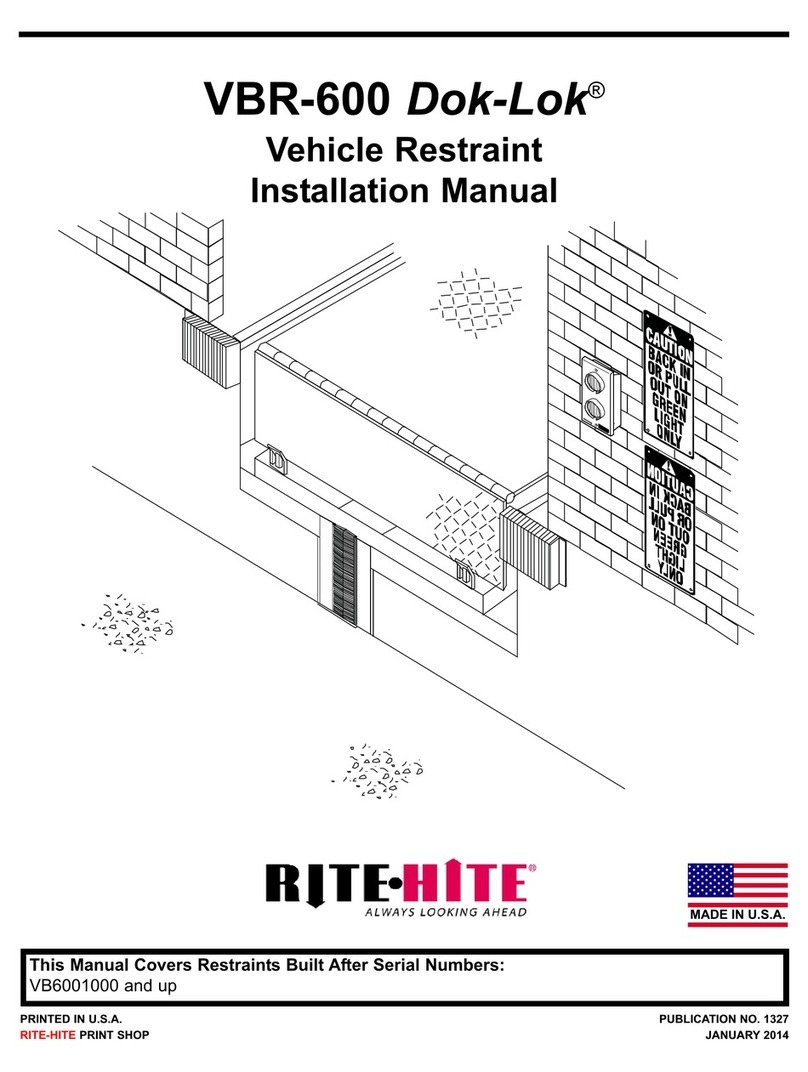

OPERATION

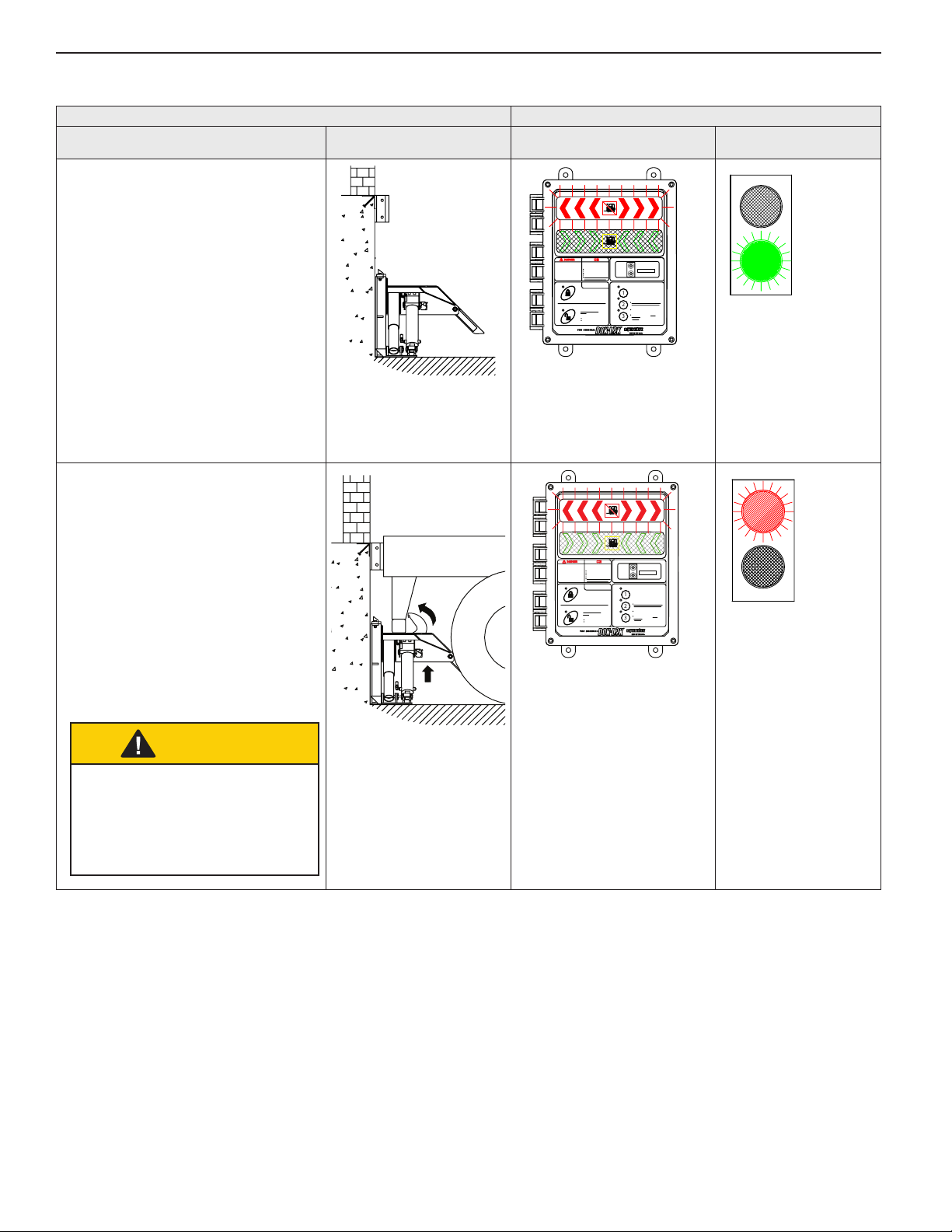

RESTRAINT DEFAULT STATUS

STATE POSITION

CONTROL BOX:

INSIDE LIGHTS, SOUND OUTSIDE LIGHTS

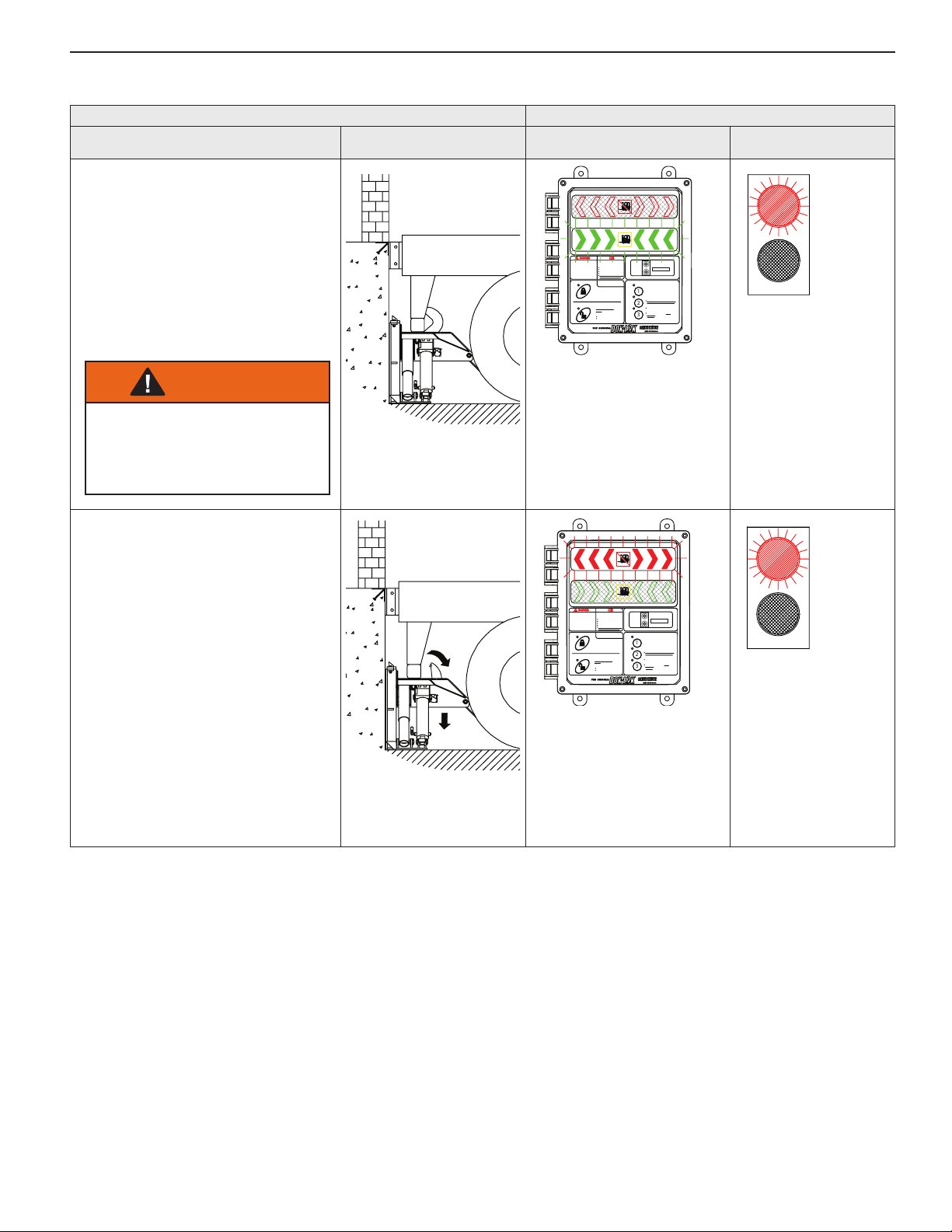

Restraint LOCKED

When R.I.G. is entrapped by

hook and carriage is supported

by support cylinders, a LOCKED

condition exists.

If during loading/unloading inside

light turns red and horn sounds,

press LOCK button to secure

R.I.G.

WARNING

Visually conrm DOK‑LOK

barrier obstructs R.I.G. of

trailer being serviced, before

operating dock leveler.

OUTSIDE LIGHT

STATUS

CONTROL BOX

STATUS

RESTRAINT POSITION

Outside Lights

Inside Lights

GREEN

RED

OUTSIDE LIGHTS

Checkoutside lights when

bothLEDs are o.

UNLOCK

LOCK

1

3

2

HORN OVERRIDE

DOK-LOK®

DO NOT ENTER TRAILER

ENTER TRAILER

Visually inspect before loading/

unloading vehicle. DOK-LOK

hook must secure rear impact

guard. See warnings on side

panel.

Additional warning labels,

manuals and other information

are available by calling:

1-800-456-0600

If red light is on and/or horn

sounds, DOK-LOK is not

properly engaged.

Check operation of DOK-LOK.

Vehicle may not be against dock.

R.I.G. may not be compatible.

Hook travel may be obstructed.

Before using "HORN OVERRIDE,"

secure vehicle by other means.

Reset system by engaging "HORN

OVERRIDE" control again. Then repeat

"UNLOCK

" operation.

When in "HORN OVERRIDE" mode:

Both red and green Lights flash. "LOCK" and

"UNLOCK" controls are not functional.

Horn can be silenced by engaging

"HORN OVERRIDE" control.

Before using "HORN OVERRIDE," secure

vehicle by other means prior to entering.

If horn and red light are on

after "UNLOCK" control is

pressed,hook may be held

by R.I.G.

To release hook:

Back trailer up against dock.

Repeat "UNLOCK" operation.

OUTSIDE LIGHT

STATUS

CONTROL BOX

STATUS

RESTRAINT POSITION

Outside Lights

Inside Lights

GREEN

RED

OUTSIDE LIGHTS

Checkoutside lights when

bothLEDs are o.

UNLOCK

LOCK

1

3

2

HORN OVERRIDE

DOK-LOK®

DO NOT ENTER TRAILER

ENTER TRAILER

Visually inspect before loading/

unloading vehicle. DOK-LOK

hook must secure rear impact

guard. See warnings on side

panel.

Additional warning labels,

manuals and other information

are available by calling:

1-800-456-0600

If red light is on and/or horn

sounds, DOK-LOK is not

properly engaged.

Check operation of DOK-LOK.

Vehicle may not be against dock.

R.I.G. may not be compatible.

Hook travel may be obstructed.

Before using "HORN OVERRIDE,"

secure vehicle by other means.

Reset system by engaging "HORN

OVERRIDE" control again. Then repeat

"UNLOCK

" operation.

When in "HORN OVERRIDE" mode:

Both red and green Lights flash. "LOCK" and

"UNLOCK" controls are not functional.

Horn can be silenced by engaging

"HORN OVERRIDE" control.

Before using "HORN OVERRIDE," secure

vehicle by other means prior to entering.

If horn and red light are on

after "UNLOCK" control is

pressed,hook may be held

by R.I.G.

To release hook:

Back trailer up against dock.

Repeat "UNLOCK" operation.

Green (flashing)

Alerts operator a safe

condition exists.

OUTSIDE LIGHT

STATUS

CONTROL BOX

STATUS

RESTRAINT POSITION

Outside Lights

Inside Lights

OUTSIDE LIGHTS

Checkoutside lights when

bothLEDs are o.

UNLOCK

LOCK

1

3

2

HORN OVERRIDE

DOK-LOK®

DO NOT ENTER TRAILER

ENTER TRAILER

Visually inspect before loading/

unloading vehicle. DOK-LOK

hook must secure rear impact

guard. See warnings on side

panel.

Additional warning labels,

manuals and other information

are available by calling:

1-800-456-0600

If red light is on and/or horn

sounds, DOK-LOK is not

properly engaged.

Check operation of DOK-LOK.

Vehicle may not be against dock.

R.I.G. may not be compatible.

Hook travel may be obstructed.

Before using "HORN OVERRIDE,"

secure vehicle by other means.

Reset system by engaging "HORN

OVERRIDE"control again.Then repeat

"UNLOCK

" operation.

When in "HORN OVERRIDE" mode:

Both red and green Lights flash. "LOCK" and

"UNLOCK" controls are not functional.

Horn can be silenced by engaging

"HORN OVERRIDE" control.

Before using "HORN OVERRIDE," secure

vehicle by other means prior to entering.

If horn and red light are on

after "UNLOCK" control is

pressed,hook may be held

by R.I.G.

To release hook:

Back trailer up against dock.

Repeat "UNLOCK" operation.

Red (flashing)

Alerts truck driver

not to move.

Restraint UNLOCKING

(UNLOCK button pressed)

Hook travels from LOCKED

position to STORED position

while support cylinders retract to a

STORED position.

If horn sounds go to FAULT State

from UNLOCKING State.

OUTSIDE LIGHT

STATUS

CONTROL BOX

STATUS

RESTRAINT POSITION

Outside Lights

Inside Lights

GREEN

RED

OUTSIDE LIGHTS

Checkoutside lights when

bothLEDs are o.

UNLOCK

LOCK

1

3

2

HORN OVERRIDE

DOK-LOK®

DO NOT ENTER TRAILER

ENTER TRAILER

Visually inspect before loading/

unloading vehicle. DOK-LOK

hook must secure rear impact

guard. See warnings on side

panel.

Additional warning labels,

manuals and other information

are available by calling:

1-800-456-0600

If red light is on and/or horn

sounds, DOK-LOK is not

properly engaged.

Check operation of DOK-LOK.

Vehicle may not be against dock.

R.I.G. may not be compatible.

Hook travel may be obstructed.

Before using "HORN OVERRIDE,"

secure vehicle by other means.

Reset system by engaging "HORN

OVERRIDE" control again. Then repeat

"UNLOCK

" operation.

When in "HORN OVERRIDE" mode:

Both red and green Lights flash. "LOCK" and

"UNLOCK" controls are not functional.

Horn can be silenced by engaging

"HORN OVERRIDE" control.

Before using "HORN OVERRIDE," secure

vehicle by other means prior to entering.

If horn and red light are on

after "UNLOCK" control is

pressed,hook may be held

by R.I.G.

To release hook:

Back trailer up against dock.

Repeat "UNLOCK" operation.

OUTSIDE LIGHT

STATUS

CONTROL BOX

STATUS

RESTRAINT POSITION

Outside Lights

Inside Lights

GREEN

RED

OUTSIDE LIGHTS

Checkoutside lights when

bothLEDs are o.

UNLOCK

LOCK

1

3

2

HORN OVERRIDE

DOK-LOK®

DO NOT ENTER TRAILER

ENTER TRAILER

Visually inspect before loading/

unloading vehicle. DOK-LOK

hook must secure rear impact

guard. See warnings on side

panel.

Additional warning labels,

manuals and other information

are available by calling:

1-800-456-0600

If red light is on and/or horn

sounds, DOK-LOK is not

properly engaged.

Check operation of DOK-LOK.

Vehiclemay not be against dock.

R.I.G. may not be compatible.

Hook travel may be obstructed.

Before using "HORN OVERRIDE,"

secure vehicle by other means.

Reset system by engaging "HORN

OVERRIDE" control again. Then repeat

"UNLOCK

" operation.

When in "HORN OVERRIDE" mode:

Both red and green Lights flash. "LOCK" and

"UNLOCK" controls are not functional.

Horn can be silenced by engaging

"HORN OVERRIDE" control.

Before using "HORN OVERRIDE," secure

vehicle by other means prior to entering.

If horn and red light are on

after "UNLOCK" control is

pressed,hook may be held

by R.I.G.

To release hook:

Back trailer up against dock.

Repeat "UNLOCK" operation.

Red (steady)

Alerts operator that an

unsafe condition exists

while hook and support

cylinders are in transit.

OUTSIDE LIGHT

STATUS

CONTROL BOX

STATUS

RESTRAINT POSITION

Outside Lights

Inside Lights

OUTSIDE LIGHTS

Checkoutside lights when

bothLEDs are o.

UNLOCK

LOCK

1

3

2

HORN OVERRIDE

DOK-LOK®

DO NOT ENTER TRAILER

ENTER TRAILER

Visually inspect before loading/

unloading vehicle. DOK-LOK

hook must secure rear impact

guard. See warnings on side

panel.

Additional warning labels,

manuals and other information

are available by calling:

1-800-456-0600

If red light is on and/or horn

sounds, DOK-LOK is not

properly engaged.

Check operation of DOK-LOK.

Vehiclemay not be against dock.

R.I.G. may not be compatible.

Hook travel may be obstructed.

Before using "HORN OVERRIDE,"

secure vehicle by other means.

Reset system by engaging "HORN

OVERRIDE"control again.Then repeat

"UNLOCK

" operation.

When in "HORN OVERRIDE" mode:

Both red and green Lights flash. "LOCK" and

"UNLOCK" controls are not functional.

Horn can be silenced by engaging

"HORN OVERRIDE" control.

Before using "HORN OVERRIDE," secure

vehicle by other means prior to entering.

If horn and red light are on

after "UNLOCK" control is

pressed,hook may be held

by R.I.G.

To release hook:

Back trailer up against dock.

Repeat "UNLOCK" operation.

Red (flashing)

Alerts truck driver

not to move.