Digital Controller

REX-C100/C400/C410/C700/C900

INSTRUCTION MANUAL

IMNZC22-E1

Th nk you for purch sing this RKC product. In order to chieve m ximum perform nce

nd ensure proper oper tion of your new instrument, c refully re d ll the instructions

in this m nu l. Ple se pl ce the m nu l in convenient loc tion for e sy reference.

To prevent injury to persons, d m ge to instrument nd equipment,

suit ble extern l protection device sh ll be required.

All wiring must be completed before power is turned on to prevent

electric shock, fire or d m ge to instrument nd equipment.

This instrument must be used in ccord nce with the specific tions

to prevent fire or d m ge to instrument nd equipment.

This instrument is not intended for use in loc tions subject to

fl mm ble or explosive g ses.

Do not touch high-volt ge connections such s power supply

termin ls, etc. to void electric shock.

RKC is not responsible if this instrument is rep ired, modified or

dis ssembled by other th n f ctory- pproved personnel.

M lfunction c n occur nd w rr nty is void under these conditions.

This product is intended for use with industri l m chines, test nd

me suring equipment. (It is not designed for use with medic l

equipment nd nucle r energy.)

This is Cl ss A instrument. In domestic environment, this instrument

m y c use r dio interference, in which c se the user m y be required to

t ke ddition l me sures.

This instrument is protected from electric shock by reinforced insul tion.

Provide reinforced insul tion between the wire for the input sign l nd

the wires for instrument power supply, source of power nd lo ds.

Be sure to provide n ppropri te surge control circuit respectively for

the following:

- If input/output or sign l lines within the building re longer th n 30 meters.

- If input/output or sign l lines le ve the building, reg rdless the length.

This instrument is designed for inst ll tion in n enclosed instrument tion

p nel. All high-volt ge connections such s power supply termin ls must

be enclosed in the instrument tion p nel to void electric shock by

oper ting personnel.

All prec utions described in this m nu l should be t ken to void

d m ge to the instrument or equipment.

All wiring must be in ccord nce with loc l codes nd regul tions.

All wiring must be completed before power is turned on to prevent

electric shock, instrument f ilure, or incorrect ction. The power must be

turned off before rep iring work for input bre k nd output f ilure

including repl cement of sensor, cont ctor or SSR, nd ll wiring must

be completed before power is turned on g in.

To prevent instrument d m ge s result of f ilure, protect the power line nd

the input/output lines from high currents with suit ble overcurrent protection

device with dequ te bre king c p city such s fuse, circuit bre ker, etc.

Prevent met l fr gments or le d wire scr ps from f lling inside

instrument c se to void electric shock, fire or m lfunction.

Tighten e ch termin l screw to the specified torque found in the m nu l

to void electric shock, fire or m lfunction.

For proper oper tion of this instrument, provide dequ te ventil tion for

he t dispens tion.

Do not connect wires to unused termin ls s this will interfere with

proper oper tion of the instrument.

Turn off the power supply before cle ning the instrument.

Do not use vol tile solvent such s p int thinner to cle n the

instrument. Deform tion or discolor tion will occur. Use soft, dry cloth

to remove st ins from the instrument.

To void d m ge to instrument displ y, do not rub with n br sive

m teri l or push front p nel with h rd object.

When high l rm with hold ction is used for Al rm function, l rm does

not turn on while hold ction is in oper tion. T ke me sures to prevent

overhe ting which m y occur if the control device f ils.

NOTICE

This m nu l ssumes th t the re der h s fund ment l knowledge of

the principles of electricity, process control, computer technology nd

communic tions.

The figures, di gr ms nd numeric v lues used in this m nu l re only

for purpose of illustr tion.

RKC is not responsible for ny d m ge or injury th t is c used s

result of using this instrument, instrument f ilure or indirect d m ge.

RKC is not responsible for ny d m ge nd/or injury resulting from the

use of instruments m de by imit ting this instrument.

Periodic m inten nce is required for s fe nd proper oper tion of this

instrument. Some components h ve limited service life, or

ch r cteristics th t ch nge over time.

Every effort h s been m de to ensure ccur cy of ll inform tion

cont ined herein. RKC m kes no w rr nty expressed or implied, with

respect to the ccur cy of the inform tion. The inform tion in this

m nu l is subject to ch nge without prior notice.

No portion of this document m y be reprinted, modified, copied,

tr nsmitted, digitized, stored, processed or retrieved through ny

mech nic l, electronic, optic l or other me ns without prior written

pprov l from RKC.

1. PRODUCT CHECK

1) Control action

F: PID ction with utotuning (Reverse ction)

D: PID ction with utotuning (Direct ction)

W: He t/Cool PID ction with utotuning (W ter cooling)

1

A : He t/Cool PID ction with utotuning (Air cooling)

1

2) Input type

,

3) Range code

Refer to “9. INPUT RANGE TABLE.”

4) First control output [OUT1] Heat-side)

M: Rel y cont ct G: Trigger for tri c driving

2

V: Volt ge pulse 8: Current (4 to 20 mA DC)

5)

Second control output [OUT2] Cool-side)

3

No symbol: When control ction is F or D. M: Rel y cont ct

V: Volt ge pulse 8: Current (4 to 20 mA DC)

6)

Alarm 1 [ALM1],

7) Alarm 2 [ALM2]

N: No l rm H: Process high l rm

A: Devi tion high l rm J: Process low l rm

B: Devi tion low l rm K: Process high l rm with hold ction

C: Devi tion high/low l rm L: Process low l rm with hold ction

D: B nd l rm P: He ter bre k l rm (HBA)[CTL-6]

4

E: Devi tion high l rm S: He ter bre k l rm (HBA)[CTL-12]

4

with hold ction R: Control loop bre k l rm (LBA)

5

F: Devi tion low l rm

with hold ction

G: Devi tion high/low l rm with hold ction

1

C100 c nnot be specified in He t/Cool PID ction.

2

For the C100, when control output is trigger output for tri c driving, only the

ALM1 is v il ble.

3

For the C100, there is no second control output.

4

He ter bre k l rm (HBA) c nnot be specified in c se of ALM1. Also, it isn’t

possible to specify when control output is current output.

5

As control loop bre k l rm (LBA), only either the ALM1 or ALM2 is selected.

Check th t power supply volt ge is lso the s me s th t specified

when ordering.

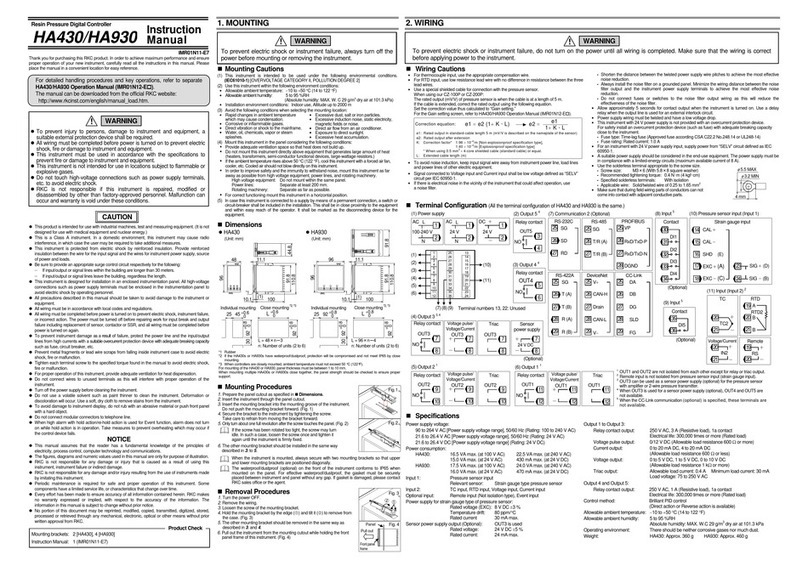

2. MOUNTING

2.1 Mounting Cautions

(1) This instrument is intended to be used under the following environment l

conditions. IEC61010-1)

[OVERVOLTAGE CATEGORY II, POLLUTION DEGREE 2]

(2) Use this instrument within the following environment conditions:

Allow ble mbient temper ture: 0 to 50 C

Allow ble mbient humidity: 45 to 85 % RH

Inst ll tion environment conditions: Indoor use, Altitude up to 2000 m

(3) Avoid the following conditions when selecting the mounting loc tion:

R pid ch nges in mbient temper ture which m y c use condens tion.

Corrosive or infl mm ble g ses.

Direct vibr tion or shock to the m infr me.

W ter, oil, chemic ls, v por or ste m spl shes.

Excessive dust, s lt or iron p rticles.

Excessive induction noise, st tic electricity, m gnetic fields or noise.

Direct ir flow from n ir conditioner.

Exposure to direct sunlight.

Excessive he t ccumul tion.

(4) Mount this instrument in the p nel considering the following conditions:

Provide dequ te ventil tion sp ce so th t he t does not build up.

Do not mount this instrument directly bove equipment th t gener tes

l rge mount of he t (he ters, tr nsformers, semi-conductor function l

devices, l rge-w tt ge resistors.)

If the mbient temper ture rises bove 50 C, cool this instrument with

forced ir f n, cooler, etc. Cooled ir should not blow directly on this

instrument.

In order to improve s fety nd the immunity to withst nd noise, mount

this instrument s f r w y s possible from high volt ge equipment,

power lines, nd rot ting m chinery.

High volt ge equipment: Do not mount within the s me p nel.

Power lines: Sep r te t le st 200 mm.

Rot ting m chinery: Sep r te s f r s possible.

For correct functioning mount this instrument in horizont l position.

(5) In c se this instrument is connected to supply by me ns of perm nent

connection, switch or circuit-bre ker sh ll be included in the inst ll tion.

This sh ll be in close proximity to the equipment nd within e sy re ch of

the oper tor. It sh ll be m rked s the disconnecting device for the

equipment.

Mounting brackets C100/400/410/700/900): 2

Instruction manual IMNZC22-E1): 1

<Accessories>

CAUTION

C100

-

(1)(2) (3) (4) (6)(7)

C400

C410

C700

C900

-

(1) (2) (3) (4)(5) (6)(7)

**

WARNING

!