Roadmaster AddaBRAKE 8800 User manual

Towing and Suspension Solutions

ROADMASTER,Inc.•6110NE127thAve•Vancouver,WA98682

800-669-9690•fax360-735-9300•roadmasterinc.com

85-3476rev.0208/08©2008ROADMASTER,Inc.

Owner’s Manual

Partnumber8800

Entire contents of manual must be read by owner

The AddaBRAKE serial number…

…is on a label on the underside of the unit. You

will need this number when you fill out your product

registrationcard.

Write down the serial number in the space below

andretainforfuturereference…

Serialnumber:

ThismanualhasbeenpreparedtoacquaintyouwiththeinstallationandoperationofyourAddaBRAKE,andto

provideyouwithimportantsafetyinformation.

Readyourowner’smanualcovertocover.UnderstandhowtoinstallandoperateyourAddaBRAKE,andcare-

fullyfollowtheinstructionsandsafetyprecautions.

YourAddaBRAKEhasaone-yearlimitedwarranty.Toqualifyforyourwarranty,filloutandreturntheenclosed

productregistrationcardwithin30daysofpurchase.As a bonus, we’ll extend your warranty to a total of two

years at no additional cost, if we receive the product registration card within 30 days of purchase.

Wethankyouforyourpatronageandgreatlyappreciateyourdiscerningtaste.

WELCOME TO THE ROADMASTER FAMILY!

IMPORTANT NOTICE!

Safety Definitions

Thismanualcontainsinformationthatisveryimportanttoknowandunderstand.Thisinformationisprovidedfor

safetyandtoprevent equipment problems.Tohelprecognizethisinformation,observethefollowingsymbols:

WARNING indicates a potentially hazardous situ-

ation which, if not avoided, could result in property

damage, serious personal injury, or even death.

CAUTION indicates a potentially hazardous situ-

ation which, if not avoided, may result in property

damage, or minor or moderate personal injury.

CAUTION used without the safety alert symbol

indicates a potentially hazardous situation which,

if not avoided, may result in property damage.

NOTE

Refers to important information and is placed in italic

type. It is recommended that you take special notice of

these items.

AddaBRAKE specifications

Height ...........................................................12inches

Width........................................................ 11.25inches

Length...........................................................16inches

Weight...................................................... 15.5pounds

Voltage...................................................... 12voltsDC

Operatingtemperaturerange

...............................-2°to+150°F(-19°to+66°C)

Lengthofstandardpowercord.....................42inches

Maximumamperagedraw .......................... 10.8amps

Idleamperagedraw............................................ 11mA

Approximatemaximumairpressure .................. 60psi

Maximumforceextendedonbrakepedal ...... 106lbs.

MinimumspaceAddaBRAKEcanfit ............16inches

TABLE OF CONTENTS

Specifications....................................insidefrontcover

Safetydefinitions ..............................insidefrontcover

Components............................................................... 2

Wiringdiagrams......................................................... 3

Initial Installation

Beforeyoubegintheinitialinstallation

(installer’schecklist) ........................................... 4-5

Initialinstallation ................................................... 6-11

Installthebreakawaysystem ............................... 6

Modificationstothe

towedvehicle’slightingsystem ...................... 6-7

Installthemotorhomemonitor

wiringharnessinthetowedvehicle ............... 7-8

Attachthebrakesignalwire............................... 8-9

Attachthefirewallgrommet;

attachthewiringconnectors ....................... 9-10

InstallthemotorhomemonitorLED..................... 10

Testthebrakingsystem ................................. 10-11

Day-to-Day Operation

Attachthepedalclamp....................................... 12-13

Adjustthefeetandtheseatpad ........................ 13-14

Pluginthepowercord ....................................... 14-15

Testandadjustpositioning;

depletethevacuuminthepowerbrakes ............ 15

Setthebrakepressure ............................................ 16

Connectthewiringharness;

testthebreakawaysystem............................ 16-17

Connectthemotorhomemonitorpatchcord ........... 17

Testthebrakingsystem...................................... 17-18

Protection Modes

Extendedbrakingprotection.................................... 18

Respondingtoanaudioalert .................................. 18

Quick Reference Checklist

ConnectingAddaBRAKE .................................... 19-20

DisconnectingAddaBRAKE..................................... 20

Troubleshooting .................................................. 21-22

Ford‘neutraltow’vehicles.................................. 23-24

Optionalequipment.................................................. 25

Limitedwarranty ...................................................... 26

Index........................................................................ 27

Read all instructions before installing or oper-

ating AddaBRAKE. Failure to understand how to

install or operate AddaBRAKE could result in prop-

erty damage, personal injury or even death.

Not for use on older vehicles without power

brakes. AddaBRAKE is designed to work with ve-

hicles that have a power brake system (even though

the power brakes are not activated while towing).

Using AddaBRAKE on vehicles that do not have

power brakes will result in over-braking and severe

non-warranty brake damage.

Do not install AddaBRAKE in a vehicle with an

‘active’ braking system.

‘Active’ (or, ‘continuous power assist’) braking

systems are a safety feature on some new vehicles.

This feature allows the brakes to always have pow-

er, even with the ignition off. The only supplemental

braking system that ROADMASTER manufactures

for these vehicles is BrakeMaster, with the addition

of a Brake Pressure Reducer (part number 900002).

If any ROADMASTER supplemental braking sys-

tem other than a BrakeMaster with a Brake Pres-

sure Reducer is installed, the vehicle will brake

with excessive force, which will damage the tires.

Other non-warranty damage may also occur.

It is the owner’s responsibility (or if profession-

ally installed, the installer’s responsibility) to de-

termine if the vehicle being equipped with supple-

mental brakes has an active braking system — refer

to the owner’s manual, the vehicle manufacturer or

the dealership.

ROADMASTER expressly disallows any and all

claims relating to tire damage, brake damage, or

any other damage to vehicles with ‘active’ braking

systems caused by: 1) installation of any ROAD-

MASTER supplemental braking system other than

BrakeMaster; or 2) failure to install a Brake Pres-

sure Reducer with the BrakeMaster.

1

COMPONENTS

2

part

number description

1 9329 ....................brakepedalclamp

2 n/a .......................aircylindershaft

3 n/a .......................pressuregauge

4 n/a .......................regulatorcontrolknob

5 n/a .......................airreliefbutton

6 n/a .......................testbutton

7 650996.................adjustableseatpad

(handleassembly)

8 450952.................adjustmentknob

9 450105.................adjustablefeet

10 450103.................12-voltpowercord 8

9

4

13

2

5

Itemsnotshowntoscale.

Optionalequipmentislistedinthe

“OptionalEquipment”section.

6

16

3

10

11

7

part

number description

11 650906.................AddaBRAKEwiringharness

12 650900.................breakawaywiringharness

13 8602 ....................breakawaycable

14 650898.................breakawayswitch

15 650906-01 ...........brakesignalwire

16 300065-00 ...........motorhomemonitorLED

17 9325 ....................audiosignalcircuitboard

18 450008.................motorhomemonitorpatch

cord(notpictured)

1

15

17 12

14

3

1. ALWAYS CHECK THE ROADMASTER WEB SITE —

www.roadmasterinc.com—forvehicle-specificinforma-

tion.Select‘Vehicle-SpecificInfo,’enterthemotorhome

andtowedvehiclemake,modelandyear,thenselect

‘BrakingSystems.’

2. If the battery must be disconnectedfortowing,

a12-voltoutletkit(partnumber9332)andastoplight

switchmustbeinstalled.ROADMASTERmanufactures

stop light switch kits for a number of vehicles; to

see if one is available for any specific vehicle, visit

www.roadmasterinc.com and select ‘Vehicle-Specific

Info,' enter the vehicle make, model and year, then

select‘BrakingSystems'andscrolldownthepage.

Note: if a stop light switch kit is listed on the web

site for any particular vehicle, it is required.

Note: an Automatic Battery Disconnect (part number

765) is available for vehicles which must be towed with

the battery disconnected. If you choose to install the

Automatic Battery Disconnect, a 12-volt outlet kit and a

stop light switch are still required; the Brake-Lite Relay

(see below) is not required.

3. If fuse(s) must be removed from the vehicle be-

fore it can be towed—verifythatremovingthefuse(s)

willnotdisruptpowertoAddaBRAKE,orotherwiseaf-

fecttheinstallationoroperation.

4. Check the towed vehicle’s 12-volt outlet for

correct power —AddaBRAKEispoweredthroughthe

12-voltoutlet,withtheignitionkeyturnedtothe“tow”

position.However, somevehiclesonly have powerat

the 12-volt outlet when the engine is running. Before

you begin the initial installation, verify that you have

power at the towed vehicle’s 12-volt outlet with the

ignitionkeyturnedtothe“tow”position.

Ifthereisnopower,youcaninstalltheoptional12-

voltoutletkit(partnumber9332).Wheninstalled,this

kitwill providepower to the12-volt outleteven when

theengineisoff.

5. Check the 12-volt outlet sockettomakecertain

that:a)thesockethasbeenwiredcorrectly;andb)the

socketisnotcorroded.

a. Make certain that the socket has been wired cor-

rectly—thecontactpointatthebottomofthesocket

shouldbepositive,andtheoutershellaroundthetop

ofthesocketshouldbenegative.

If the socket’s positive and negative connections

have been reversed, the fuse in the AddaBRAKE

power cord will blow when the cord is plugged into

the 12-volt outlet.

b. Make certain that the socket is not corroded

or otherwise damaged—acorrodedsocketmaynot

provide constant power to AddaBRAKE, which may

Before you begin the initial installation…

causeintermittentoperation.

Ifthesocketiscorrodedordamaged,youcanin-

stalltheoptional12-voltoutletkit(partnumber9332).

Wheninstalled,thiskitwillprovideconstantpowerto

AddaBRAKE.

If the towed vehicle has a single 12-volt outlet

which has been used to heat a cigarette lighter plug,

install the optional 12-volt outlet kit for the Adda-

BRAKE power supply.

Using a cigarette lighter plug in a 12-volt socket

will corrode the contact points. The socket will not

supply sufficient voltage to be used as the Adda-

BRAKE power source — AddaBRAKE may not oper-

ate, or may only operate intermittently.

6. The circuit at the towed vehicle’s 12-volt outlet

must be rated at NO LESS THAN 15 AMPStopower

AddaBRAKE.Checkthefuseattheoutlet—ifthefuse

isratedat15ampsorhigher,thecircuitisadequateto

powerAddaBRAKE.Ifthefuseisratedatlessthan15

amps,installtheoptional12-voltoutletkit(partnumber

9332). When installed, this kit will provide power to

AddaBRAKE.

If the circuit at the 12-volt outlet is rated at less

than 15 amperes, install the optional 12-volt outlet

kit. Depending on the available current during tow-

ing, AddaBRAKE may not function, or may function

incorrectly, without at least 15 amps.

If the circuit is rated at less than 15 amps, do not

simply replace the outlet’s fuse with a higher-am-

perage fuse. This will cause the wiring to overheat,

which can cause wiring damage, an electrical fire,

or other consequential, non-warranty damage.

Failure to follow these instructions may cause

property damage, personal injury or even death.

7. Check the towed vehicle’s brake lights—Adda-

BRAKE must function with the ignition key turned to

the“tow”position.However,somevehicles’brakelights

only operate with the key turned to the “on” position.

Checktoseeifthisisthecase:turntheignitionkeyto

the“tow”position,applythebrakes,andchecktosee

ifthebrakelightsilluminate.Ifthebrakelightsdonot

illuminate, a two-prong stop light switch and 10-amp

fusemustbeinstalled.

Note: check the owner’s manual to see if the vehicle

is equipped with an “automatic shut down” feature. If

continued on next page

4

Before you begin the initial installation…

continued from preceding page

this is the case, ensure that the vehicle is not in auto-

matic shut down mode before performing this test.

ROADMASTERmanufacturesstoplightswitchkits

foranumberofvehicles;toseeifoneisavailablefor

anyspecificvehicle,visitwww.roadmasterinc.comand

select ‘Vehicle-Specific Info,’ enter the vehicle make,

model and year, then select ‘Braking Systems' and

scrolldownthepage.

Note: if you must install a Brake-Lite Relay — see

step 9, below — a stop light switch is not required.

8. If the towed vehicle has a magnetic tow light

system— modificationswill benecessary,in orderto

permanentlyattachthebrakesignalwire.RefertoStep

Dunder“InitialInstallation”—“Attachthebrakesignal

wire,”step2c.

9. An optional Brake-Lite Relay may be required.

Seepageseven forinstructionsonhow todetermine

iftherelaymustbeinstalled.

Note: a stop light switch (see steps 2 and 7 above)

and a Brake-Lite Relay are mutually exclusive — if you

use one, the other is not necessary.

10. If the towed vehicle will be (or has been) wired

for towing—diodesmustbeattachedtothewires.

Theelectricalcircuitthatturnsthetowedvehicle's

brakelightsonandoffalsoturnsAddaBRAKEonand

off. If diodes are not attached, electrical feedback

through the brake light wire will prevent AddaBRAKE

from releasing braking pressure. AddaBRAKE will be

activated with the brake lights, but will not release

brakingpressureuntiltheextendedbrakingprotection

mode overrides the brake signal, after approximately

15seconds.

If the vehicle will be wired for towing, diodes

must be attached in order for AddaBRAKE to re-

lease the towed vehicle's brakes in tandem with the

motorhome. If diodes are not attached, AddaBRAKE

will apply braking pressure for approximately 15

seconds each time the motorhome brakes are ap-

plied, regardless of when the motorhome brakes

are released.

Damage to the towed vehicle's braking system, as

well as other consequential damage, may occur.

Additionaldiodesarenotrequiredif…

• …aBrake-LiteRelay(partnumber88400)mustbe

installedinthetowedvehicle;or

• …anon-intrusivewiringmethodisselected—either

ataillightwiringkit(partnumber155)ormagnetictow

lights(partnumber2100or2120).

A wiring kit with diodes is available from ROAD-

MASTER — the Universal Wiring Kit, part num-

5

ber 154. Additional diodes may also be purchased

separately. Wiring diagrams are under ‘Support’ at

www.roadmasterinc.com.

In addition to wiring and connection instructions, this section contains information about the components of

yoursupplementarybrakingsystem,andhowtheyfunction.Forthatreason,readthissection,evenifyouwill

notbeinstallingthesecomponentsyourself.

Step A

Install the break away system

“Breakaway”systemsaresecondarysafetydevices,

required by law in many states, which will brake the

towedvehicleifitseparates(“breaksaway”)fromthe

motorhome.

1. Mountthebreakawayswitch(Figure1)atthefront

ofthevehicle,onthedriver’sside.Chooseanareayou

caneasilyreach,withasurfaceofsufficientstrengthto

holdtheswitchfirmlyinplace,sothatthebreakaway

pin(Figure1)willpullfreelyfromtheswitch.Mountthe

switchinahorizontalposition,withthebreakawaypin

facingtowardthemotorhome.

Ensurethatthebreakawaypincanbepulledfree-

ly away from the towed vehicle, without any obstruc-

tions.

Do not attach the break away switch to the tow

bar or the tow bar bracket. If the tow bar or bracket

fails, the break away switch will separate with it,

preventing the break away system from activating.

If the towed vehicle separates, the brakes will not

be applied, which may cause property damage, per-

sonal injury or even death.

2. Thebreakawaywiringharness(Figure1)connects

thebreakawayswitchtoAddaBRAKE.Itwillberouted

throughthefirewall,onthedriver’sside.

Lookforapre-existingholeinthefirewall(or,ifthere

is sufficient space, a pre-existing grommet with other

wiring)closetotheflooronthedriver’sside,toroute

thebreakawaywiringharnessthroughthefirewall.

Note: the motorhome monitor wiring harness (Step

C) and the brake signal wire (Step D) will also be routed

through this hole.

Ifthereisnopre-existingholeorgrommetwithsuf-

ficientspace,drilla1/2"holethroughthefirewall.

Drillfromtheenginecompartmentorfromthein-

terior of the vehicle, whichever is more convenient.

Beforedrilling,makecertainyouwillnotdamageany

componentsontheothersideofthefirewall.

3. Routethewiringharnessfromthebreakawayswitch

tothefirewall(or,fromthefirewalltothebreak away

switch,whicheverismoreconvenient),avoidinglines,

hoses,movingpartsor“hot”componentssuchasex-

haustsystems.

Whereappropriate,usewiretiestosecurethebreak

Figure 1

INITIAL INSTALLATION

awaywiringharness.

Atthefrontofthevehicle,connectthewiringhar-

nesstothebreakawayswitch.

Youwillconnectthebreakawaywiringharnessto

AddaBRAKEinalaterstep.

Step B

Modifications to the

towed vehicle’s lighting system

Asupplementalbrakingsystemwillaffecttheopera-

tion of the vehicle’s tow lighting system. Use the fol-

lowinginformationtodetermineifoptionalaccessories

mustbeinstalledinavehiclewhichhasbeenwiredfor

towing — or, if no lighting system has been installed,

whichsystemsareappropriate.

1. First, identify the type of brake and turn signals

in the vehicle. There are two types — combined or

separate.Inacombinedsystem(Figure2),thebrake

continued on next page

6

Modifications to the towed

vehicle’s lighting system

continued from preceding page

lightdoestheflashingfortheturnsignal;inaseparate

system(Figure2), there are amber or red turnsignal

lightswhichareseparatefromthebrakelights.

2. Next,testtoseeifthetowedvehicle’sbrakelights

willilluminatewiththeengineoff—turntheignitionkey

tothe“tow”position,pressthebrakepedal,andcheck

thebrakelights.

3. Basedonwhetherornotthebrakelightsilluminate,

andthetypeofbrakeandturnsignals,therearethree

possibilities:1)thebrakelightsilluminateandthetowed

vehicle has combined lighting; 2) the brake lights il-

luminateandthetowedvehiclehasseparatelighting;

or 3) the brake lights do not illuminate. Choose from

the appropriate list below to install either an optional

accessoryoranotherlightingsystem.

(If you choose to install a system of diodes and

rewire the vehicle’s turn signals, taillights and brake

lights for towing, wiring diagrams are available at

www.roadmasterinc.com.)

1. If the brake lights illuminate and the

towed vehicle has combined lighting…

…oneofthethreealternativesbelowisrequired.

A. Asystemofdiodes

(the vehicle’s turn sig-

nals,taillightsandbrake

lightshavebeenrewired

for towing) with an op-

tionalBrake-LiteRelay.

(Thismethodcannot

beusedinFordvehicles

with ‘neutral tow’ kits.

See “Ford ‘neutral tow’

vehicles,”inthismanual,

forwiringinstructions.)

B. Install a “bulb and

socketset”(alsocalleda

“taillight wiring kit,” part

number155).

C. Install a magnetic

towlightsystem(partnumber2100or2120).

2. If the brake lights illuminate and the

towed vehicle has separate lighting…

…oneofthefouralternativesbelowisrequired.

A. Asystemofdiodes(thevehicle’sturnsignals,tail-

lights and brake lights have been rewired for towing)

withanoptionalBrake-LiteRelay.

(ThismethodcannotbeusedinFordvehicleswith

‘neutraltow’kits. See“Ford ‘neutraltow’vehicles,”in

thismanual,forwiringinstructions.)

B. Asystemofdiodeswith the diodes jumped.This

methodisalsousedtowireFordvehicleswith‘neutral

tow’kits.SeeFigure15.

C. Installa“bulbandsocketset”(alsocalleda“taillight

wiringkit,”partnumber155).

D. Install a magnetic tow light system (part number

2100or2120).

3. If the brake lights do not illuminate…

…an optional stop light switch must be installed.

ROADMASTERmanufacturesstoplightswitchkitsfor

anumberofvehicles;visitwww.roadmasterinc.comfor

themostcurrentlistofavailablekits.

Anyoneofthefollowingtowlightingsystemsmust

alsobeinstalledwiththestoplightswitch:

• asystemofdiodes(thevehicle’sturnsignals,tail-

lightsandbrakelightshavebeenrewiredfortowing)

• a “bulb and socket set” (also called a “taillight

wiringkit,”partnumber155)

• amagnetictowlightsystem(partnumber2100or

2120)

Step C

Install the motorhome monitor

wiring harness in the towed vehicle

When the components of the motorhome monitor

areinstalledandconnected,anLEDonthemotorhome

dashboardwillilluminateeachtimeAddaBRAKEisac-

tivated,confirmingthatthetowedvehicle’sbrakeshave

beenapplied.

Note: there are two lengths of black wire in this kit,

each with a female bullet connector at one end. Use

the short length of wire in this step.

1. Chooseamountingpointatthefrontofthevehicle,

near the electrical socket, for the end of the harness

withthefemalebulletconnector.Attachtheconnector

withoneormoreoftheincludedwireties.Allowenough

slacksothatamalebulletconnectorcanbeplugged

intoandoutofit.

Note: if there is an open terminal available on both

electrical sockets, you can use the existing electrical

cord to connect the monitor wiring between the two

vehicles. This method eliminates a separate patch cord,

included with AddaBRAKE for the same purpose. If you

choose this method, cut the female bullet connector off,

and attach the monitor wire to the open terminal on the

towed vehicle’s electrical socket. Later, you will use the

matching terminal on the motorhome’s electrical socket

to complete the connection.

continued on next page

INITIAL INSTALLATION

Figure 2

7

Install the motorhome monitor

wiring harness in the towed vehicle

continued from preceding page

Note: if you choose this method, keep the patch

cord. If a second towed vehicle is added later, it may

not have an open terminal available on the electrical

socket.

2. Oncethefemalebulletconnectorisattached,route

the monitor wiring harness through the engine com-

partment, to the driver’s side of the firewall. Use the

sameroute as the breakaway wiring harness,if that

is convenient. As before, avoid lines, hoses, moving

parts or “hot” components such as exhaust systems.

Whereappropriate,usewire tiestosecurethewiring

harnessinplace.

3. Routethemotorhomemonitorwiringharnessthrough

thesameholeasthebreakawaywiringharness(Step

A).

4. Next,locatethetowedvehicle’sbrakelightswitch

and,withatestlight,findthe“cold”sideofthebrake

light switch — the “cold” side of the switch does not

register voltage unless the brakes are applied. With

a12-voltmeter,verifythatyouhavefound 12VDC+.

Then,removethevehicle’sbrakelightfuse,locatedin

thevehicle’sfusepanel.

Failure to remove the brake light fuse from the

vehicle’s fuse panel may cause the vehicle’s theft

deterrent system, or other electrical system indica-

tors, to be activated if the brake pedal is depressed

during the installation. This may require non-war-

ranty repair to the vehicle.

5. Cutthebrakelightwire,afewinchesdownstream

fromthe“cold”sideofthebrakelightswitch.

If the Brake-Lite Relay is required…

(seetheprevioussection—“Modifications

tothetowedvehicle’slightingsystem”)

Install the Brake-Lite Relay now. The installation

instructionsareincludedwiththerelay.AftertheBrake-

LiteRelayisinstalled,proceedtoStepD—“Attachthe

brakesignalwire.”

Note: do not install the Brake-Lite Relay unless it

is required. Refer to the previous section — “Modifica-

tions to the towed vehicle’s lighting system.”

If the Brake-Lite Relay is not required…

(seetheprevioussection—“Modifications

tothetowedvehicle’slightingsystem”)

6. Ifnecessary,trimthemonitorwiringharness,then

attach the monitor wire to the brake light wire, using

thesuppliedyellowbuttconnector.

7. Ensurethatthemonitorwiringharnesswillnotpres-

entanobstacleorhazardtothedriverofthevehicle,

orinterferewiththeoperationofthevehicle.Useone

or more wire ties, if necessary, to secure the wiring

harnessoutoftheway.

8. Reinstallthebrakelightfuse,whichyouremoved

instep4.

Step D

Attach the brake signal wire

Thebrakesignalwireisattachedtothebrakelight

wire(s)inthetowedvehicle’selectricalharness.When

the brake signal wire is connected to AddaBRAKE

(alongwith the othercomponents of thebraking sys-

tem), AddaBRAKE will be activated when the towed

vehicle’sbrakelightsareactivated.

Note: the brake signal wire is a six-foot length of

green wire, with a female bullet connector at one end.

1. Chooseaconvenientpointonthetowedvehicle’s

towlightharnesstoattachthebrakesignalwire,and

removetheprotectiveloomcoveringthatsectionofthe

harness.

2a. Ifthetowedvehiclehascombinedbrakeandturn

signallights(Figure2)…

• Cuttheyellowwire(leftturn/brake)ontheharness,

and attach the ends with one of the supplied yellow

buttconnectors(Figure 3).Repeat forthegreen wire

(rightturn/brake).

• Then,runasmalllengthofthesuppliedwirefrom

bothbuttconnectors(Figure3),andattachbothwires

totheinputsoftheincludeddiode(Figure3)withtwo

ofthesuppliedspadeconnectors.

2b. Ifthetowedvehiclehasseparatebrakeandturn

signallights(Figure2),theconnectionisthesameas

above,exceptthatonlyonewire(thebrakelightwire)

isattachedtothediode…

• Withatestlight,determinewhichofthewiresinthe

towlightharnessisthebrakelightwire—whenthetest

lightisconnectedtothebrakelightwire,thetestlight

will illuminate when the motorhome’s brake pedal is

depressed.

• Cutthebrakelightwire,andconnecttheendswith

oneoftheincludedyellowbuttconnectors.

• Then,runasmalllengthofthesuppliedwirefrom

the butt connector, and attach the wire to the diode

with another spade connector. Use either one of the

twoinputs;leavetheotherinputempty.

continued on next page

INITIAL INSTALLATION

8

INITIAL INSTALLATION

Figure 3

9

method(2a,above).

3. Usinganotherofthesuppliedspadeconnectors,at-

tachthebareendofthebrakesignalwiretotheoutput

ofthediode(Figure3).

4. Routethebrakesignalwirethroughtheenginecom-

partment, to the driver’s side of the firewall. Use the

same route as the break away wiring harness and/or

themotorhome monitorwiringharness, ifthat iscon-

venient. As before, avoid lines, hoses, moving parts

or“hot”componentssuchasexhaustsystems.Where

appropriate, use wire ties to secure the brake signal

wireinplace.

5. Routethebrakesignalwirethroughthesamehole

in the firewall as the break away wiring harness and

themotorhomemonitorwiringharness.

6. Replacetheprotectiveloom,whichyouremovedin

stepone.

Step E

Attach the firewall grommet;

attach the wiring connectors

1. Cutthroughtheincludedfirewallgrommet(Figure1)

ononeside,andslideitoverthebreakawaywiringhar-

ness,thebrakesignalwire,andthemotorhomemonitor

wiringharness.Fitthegrommetintothe1/2"holeyou

drilledinthefirewall.Feedtheremaininglengthsofthe

brakesignal wire and thebreak away wiring harness

throughthe grommet. Then, seal thegrommet witha

siliconesealant.

2. WhenAddaBRAKEisconnectedanddisconnected,

continued on next page

Attach the brake signal wire

continued from preceding page

2c.Ifthetowedvehiclehasmagnetictowlights…

Note: additional connectors and — depending on the

application — additional wiring will be necessary to wire a

magnetic tow light system.

• Peelbackasectionoftheprotectivecoveringnearthe

plugontheelectricalcable—enoughtouseatestlighton

thewiringand,later,toattachtwobuttconnectors.Then,

usingatestlight,findtheleftandrightcombinedbrake

andturnsignalwires.

• Cutoneofthecombinedbrakeandturnsignalwires,

andattachtheendswithabuttconnector.Runasmall

lengthofwirefromthebuttconnector,andattachafemale

bulletconnectortotheendofthewire.

Attachamalebulletconnectortoanothersmalllength

ofwire.Usingoneoftheincludedspadeconnectors,at-

tachtheotherendofthewiretooneoftheinputsonthe

diode.

Repeatfortheotherbrakeandturnsignalwire.

Beforetowing,connectthemaleandfemalebullet

connectors.

• Trimtheprotectivecoveringovertheelectricalcable;

wrapanyexposedwiringwithelectricaltape.

• Connecttoground—atbothvehicles,connectawire

toanygoodchassisground.Beforetowing,connectthe

groundwireswithaseparatecable.

2d. Ifthetowedvehiclehasataillight(“bulbandsocket”)

wiring kit…

• Makecertainthatagroundconnectionexistsbetween

thetowedvehicleandthemotorhome.Otherwise,thewir-

ingisidenticaltothecombinedbrakeandturnsignallight

Attach the firewall grommet;

attach the wiring connectors

continued from preceding page

the AddaBRAKE wiring harness will be plugged into

and out of the connectors on the break away wiring

harnessandthebrakesignalwire.

Withthisinmind,chooseasuitablelocationforthe

end of the break away harness and the end of the

brakesignalwire—bothconnectorsmustbewithineasy

reach,but mustnot presentan obstacleor hazardto

thedriverofthevehicle,orotherwiseinterferewiththe

operationofthevehicle.

Ifnecessary,coilthebreakawayharnessand/orthe

brakesignalwire.Then, attachthematthe pointyou

haveselected,usingoneormoreoftheincludedwire

tiestosecuretheminplace.

Step F

Install the motorhome monitor LED

Note: there are two lengths of black wire in this kit,

each with a female bullet connector at one end. Use

the long length of wire in this step.

Note: some motorhomes are manufactured with aux-

iliary wires pre-strung from the rear of the motorhome

to the dashboard, for aftermarket accessories such as

this. Call the manufacturer.

1. Attachtheendoftheblackwirewiththefemalebul-

letconnectorto thebackof themotorhome,nearthe

electricalsocket.

Attach theconnector with one ormore of the in-

cluded wire ties. Allow enough slack so that a male

bulletconnectorcanbepluggedintoandoutofit.

Note: in Step C, you may have chosen to use

open terminals on the electrical sockets to connect the

INITIAL INSTALLATION

monitor wiring between the two vehicles. If this is the

case, cut the female bullet connector off, and attach

the monitor wire to the open terminal on the motorhome

electrical socket.

2. Oncethefemalebulletconnectorisattached,route

thewirefromthebackofthemotorhometotheunder-

sideofthedashboard.Avoidlines,hoses,movingparts

(slideouts,sliding generators, slidingbattery trays) or

“hot” components such as exhaust systems. Where

appropriate, use wire ties to secure the wire to the

undercarriage.

3. ChooseanareaonthedashboardtomounttheLED.

Lookforamountingpointawayfrompre-existingwires

orcomponents,wheretheLEDcanbeeasilyseenby

thedriver.

4. Drilla5/16"holethroughthedashboardatthepoint

youhavechosen.Beforedrilling,makecertainyouwill

notdamageanycomponentsontheotherside.

5. CentertheLEDdecal(Figure4)overthehole,and

pressitdown.Or,youmaychoosetoomitthedecal,

dependingonyourpreferences.

6. Fromthetopofthedashboard,slidetheLEDthrough

thehole,wiresfirst,untilthebaseofthebulb(Figure

4)isflushtothetopofthedash.

7. Fromtheundersideofthedash,fitbothofthewires

throughthespeednut(Figure4).Thenpushthespeed

nutup,againstthedash,tosecuretheLEDinplace.

8. Usingoneormoreofthesuppliedwireties,attach

theaudiosignalcircuitboard(see“Components,”page

two)totheundersideofthedash,asclosetotheLED

aspossible.

9. Connecttopower—trimtheblackwire,whichyou

routedfromthebackofthemotorhome.(Savetheex-

cess;youmayuseitinthenextstep.)Then,connect

the black wire to both the red LED wire and the red

audiosignalwire,usingtheincludedbuttconnector.

10. Connecttoground—connecttheblackwirefromthe

LED, as well as the black wire from the audio signal

circuit board, to any good chassis ground, using the

included ring terminal. (If necessary, use any excess

wire from the preceding step to extend the length of

thetwogroundwires.)

Step G

Test the braking system

Note: the motorhome and towed vehicle must be

stationary for the system test, and ready for towing —

all components of the braking system must be properly

connected and receiving power. Then, according to the

manufacturer, make all adjustments necessary to pre-

continued on next page

Figure 4

10

functions properly.

Failure to follow these instructions may cause

property damage, personal injury or even death.

4. Confirmtheproperoperationoftheextendedbraking

mode:depressandholdthemotorhome’sbrakepedal

down. The AddaBRAKE air cylinder shaft and pedal

clampwillextend.Afterapproximately15seconds,the

aircylindershaftandpedalclampwillretract.

5. Confirmtheproperoperationoftheaudioalert:de-

pressandholdthetowedvehicle’sbrakepedaldown.

Afterapproximately20seconds,themotorhomemonitor

willactivatetheaudioalert.(Tocanceltheaudioalert,

releasethetowedvehicle’sbrakepedal.)

6. Confirmthatthemotorhometurnsignalsdonotac-

tivateAddaBRAKE.

An incorrect flasher speed may activate Adda-

BRAKE unnecessarily, causing excessive brake

wear or other consequential, non-warranty dam-

age.

If the turn signals activate AddaBRAKE, check

the turn signal flasher rating — it may be inadequate

for the motorhome-towed vehicle combination. If

this is the case, replace the flasher with one rated

at or above the number of bulbs in the motorhome-

towed vehicle combination.

Test the braking system

continued from preceding page

pare the vehicle for towing. These adjustments may

include: turning the ignition key to the “tow” position;

pulling fuses; disconnecting the battery; and setting

the transmission to a particular gear or in a particular

sequence.

Refer to the owner’s manual, or call the dealership

or the manufacturer for vehicle-specific information.

1. ConnectAddaBRAKEaccordingtotheinstructions

inthenextsectioninthismanual—“Day-to-dayopera-

tion.”

2. Confirmtheproperoperationofthesupplemental

braking system: depress and hold the motorhome’s

brakepedaldown.TheAddaBRAKEaircylindershaft

and pedal clamp will extend (after approximately two

seconds).Then,releasethebrakepedal.Atthetowed

vehicle, the AddaBRAKE air cylinder shaft and pedal

clampwillretract.

If the vehicle will be (or has been) wired for tow-

ing (as opposed to installing a taillight wiring kit or

magnetic tow lights), diodes must be attached in

order for AddaBRAKE to release the towed vehicle’s

brakes in tandem with the motorhome. If diodes are

not attached, AddaBRAKE will apply braking pres-

sure for approximately 15 seconds each time the

motorhome brakes are applied, regardless of when

the motorhome brakes are released.

Damage to the towed vehicle’s braking system,

as well as other consequential damage, may oc-

cur.

Refer to step 10 under “Before you begin the

initial installation” for additional information.

3. Confirmthatthemotorhomemonitorisfunctioning:

theLEDwillilluminateafterthemotorhome’sbrakeped-

alisdepressed(afterapproximatelytwoseconds),and

stopilluminatingwhenthebrakepedalisreleased.

If the LED does not illuminate…

…it may indicate that AddaBRAKE is wired incor-

rectly. If AddaBRAKE is wired incorrectly, it will not

brake the towed vehicle in tandem with the motor-

home. Insufficient braking pressure will lengthen

stopping distance, and may also cause a loss of

vehicular control.

Refer to the ‘Troubleshooting’ section (under

‘Electrical’) for possible causes. If AddaBRAKE

has been incorrectly wired, identify and correct

the mistake, then test to ensure that AddaBRAKE

INITIAL INSTALLATION

11

DAY-TO-DAY OPERATION

This section contains detailed operating instructions. Refer to this section until you become familiar with

eachstep.(BeforeconnectingordisconnectingAddaBRAKE,alsorefertothe“QuickReferenceChecklist”for

additionalwarningsandcautions.)

Determine if the vehicle to be towed is equipped

with pedal presets and/or automatic seat adjust-

ments. Proper installation of the braking system

may be affected by these presets; if the vehicle is

so equipped, note the original installed position and

return to that position before towing the vehicle.

If the seat and/or brake pedal are not at the origi-

nal installed position when the vehicle is towed, the

pedal clamp may apply excessive braking force,

which will damage the brake system and/or elec-

trical system and may cause brake or electrical

system failure, as well as other non-warranty dam-

age.

Failure to follow these instructions may cause

property damage, personal injury or even death.

5. Presstheairreliefbutton(Figure5)tomakecertain

thatalloftheairintheAddaBRAKEairreservoirhas

beenreleased.Ifthereisairinthereservoir,continue

tohold thebutton downuntil theair isreleased —air

inthereservoirwillpreventthecylinderfromextending

whenyouconnectthebrakepedalclamptothetowed

vehicle’sbrakepedal.

6. Continuetoholdtheairreliefbuttondown,andpull

forwardonthepedalclamp,toextendtheaircylinder

shaft.Releasetheairreliefbutton.

continued on next page

Step A

Attach the pedal clamp

1. Connect and attach the tow bar to both vehicles

(according to the manufacturer’s instructions). Then,

shift the towed vehicle’s transmission into the proper

gearfor towing (also accordingto the manufacturer’s

instructions).

To prevent the towed vehicle from rolling, con-

nect and attach the tow bar to both vehicles before

shifting the towed vehicle’s transmission into the

proper gear for towing.

2. Slidethedriver’sseatback,asfarasitwillgo.

3. Attachthe adjustableseatpad toAddaBRAKE —

screwthe adjustment knob (see“Components,” page

two) through the seat pad and into either of the two

anchorholesatthebackofAddaBRAKE.(Youwillad-

justtheseatpadinalaterstep.)

Note: depending on the available space in the towed

vehicle, the adjustable seat pad may be eliminated, if

that provides the best fit. Before attaching the seat pad,

test-fit AddaBRAKE, according to step 4 below, to see

if this is the case.

4. Now,positionAddaBRAKEbetweenthedriver’sseat

andthebrakepedal,attheapproximatepositionitwill

sitwhenconnectedtothebrakepedal.

Note: rubberized floor mats will cause AddaBRAKE

to “climb” the driver’s seat. If the vehicle has a rubber-

ized floor mat, remove it when towing.

Note: if the towed vehicle has a steering wheel tilt

latch, it may be easier to position AddaBRAKE with the

steering wheel tilted up.

Seat and/or pedal positioning systems may affect

the towed vehicle braking system.

CAUTION — for Saturn Vue and other vehicles —

If the towed vehicle’s engine must be started periodically…

Always deplete the vacuum in the vehicle’s power brake system BEFORE YOU RESUME TOWING.

If the vacuum is not released, AddaBRAKE will apply excessive force when it is activated, which will

cause severe tire and/or brake system damage to the towed vehicle. Refer to the caution statement

on pages 19 and 20 for further information.

Figure 5

12

Attach the pedal clamp

continued from preceding page

7. Pullthehairpinclip(Figure6)out,thenlifttheslot-

tedarm(Figure6)upandoutoftheway.

8. Verifythatthepedalclampisrightsideup,asshown

in Figure 6 — the arrow on the sticker will point “Up”

whenthepedalclampisproperlypositioned.

9. Then,holdtheclevis(Figure7)andpullbackonthe

spring post (Figure 7), until the tabs under the pedal

clamparewideenoughtoclearthebrakepedal.

10. Fitthepedalclampontothebrakepedal,sothat

all four tabs are hooked around it (Figure 8). Then,

releasethespringpost.

Note: on the initial fitting, it may be necessary to

adjust the tabs on the pedal clamp — use pliers to bend

any or all of the tabs so that they hook around and

under the towed vehicle’s brake pedal.

Once the tabs have been adjusted to a specific

brake pedal, no further adjustment to the pedal clamp

is necessary for that vehicle.

For every subsequent vehicle, inspect the pedal

clamp on the initial fitting. Verify that all four tabs are

hooked around and under the brake pedal. If necessary,

bend the tabs to fit, as described above.

Make certain that all four tabs on the pedal clamp

are securely hooked around the brake pedal. If the

tabs are loose, the pedal clamp can rotate out of

position and hold the brake pedal down, even when

AddaBRAKE is not activated, which will cause brake

damage or other consequential, non-warranty dam-

age.

11. Swingtheslottedarmbackoverthespringpost,fit

thespringpostthroughoneoftheslots,andreattach

thehairpinclip(Figure8).

Note: the spring post may be bent slightly with a

pair of pliers, if necessary, in order to fit it through one

of the slots.

Step B

Adjust the feet and the seat pad

1. Nowthatthepedalclampisinplace,moveAdd-

aBRAKEforward,untiltheaircylindershaftisfullyre-

tracted (Figure 9). Make certain that AddaBRAKE is

notdepressingthetowedvehicle’sbrakepedal.

Do not move AddaBRAKE too far forward, to the

DAY-TO-DAY OPERATION

Figure 6

Figure 7

Figure 8

13

extent that the pedal clamp is depressing the brake

pedal. If the brake pedal is depressed, the brakes

will be applied continuously, which will cause se-

vere tire and/or brake system damage, as well as

other consequential, non-warranty damage.

Failure to follow these instructions may cause

property damage, personal injury or even death.

continued on next page

DAY-TO-DAY OPERATION

Adjust the feet and the seat pad

continued from preceding page

2. Ifnecessary,adjustthefeetonthebottomofAdd-

aBRAKE(oneateachcorner—Figure10)upordown:

withawrench,loosen thelocknutat thetopofeach

foot,andthenturnthemclockwiseorcounterclockwise.

Makecertainthatallfourfeetaremakingcontactwith

the floor of the vehicle, and that AddaBRAKE is sta-

tionary — it should not rock back and forth. (In some

vehicles,itmaybenecessarytoremoveoneormore

ofthefeet,oritmaybenecessarytoaddoneormore

optionalfootextensions—seethe“OptionalEquipment”

sectioninthismanual.)

3. With a wrench, tighten the lock nut at the top of

eachfootextension(Figure10).

Unless the lock nuts are tightened with a wrench,

the feet may vibrate loose during towing, and Add-

aBRAKE may shift from the installed position. Un-

less AddaBRAKE is properly positioned, it will not

function at full capacity — the pedal clamp will not

apply the proper braking pressure against the brake

pedal.

4. Findabracingpointonthefrontofthedriver’sseat

for the adjustable seat pad — the seat pad stabilizes

AddaBRAKE, keeping it down as it presses against

thebrakepedal.Pressthefrontoftheseattofindthe

firmestpointfortheseatpad.

Figure 10

Note: do not brace the adjustable seat pad against

plastic trim. The plastic will crack when AddaBRAKE

is activated.

Nowthatyouhaveselectedabracingpointforthe

adjustableseatpad,loosentheadjustmentknob(see

“Components,”pagetwo)atthebackoftheseatpad,

andmovetheseatpadupordownuntilthetopofthe

seatpadmatchestheheightofthebracingpoint.

Note: the seat pad may be rotated 180 degrees or

removed entirely for a better fit. There are also two

anchor holes that the adjustment knob on the seat pad

may be threaded into, for additional fit options.

Oncetheheightisadjusted,tightentheadjustment

knobontheseatpad.

5. Next, slide the driver’s seat forward, until it just

touchestheadjustableseatpad.Ifnecessary,allowa

smallgap,ratherthanallowingAddaBRAKEtodepress

thebrakepedal.MakecertainthatAddaBRAKEisnot

depressingthetowedvehicle’sbrakepedal.

The driver’s seat must not be too far forward,

to the extent that the AddaBRAKE pedal clamp is

depressing the towed vehicle’s brake pedal.

If the brake pedal is depressed, the brakes will

be applied continuously, which will cause severe

tire and/or brake system damage, as well as other

consequential, non-warranty damage.

Failure to follow these instructions may cause

property damage, personal injury or even death.

Step C

Plug in the power cord

Check the 12-volt outlet socket before plugging

in the AddaBRAKE 12-volt power cord, to make cer-

tain that the socket has been wired correctly. The

contact point at the bottom of the socket should

be positive, and the outer shell around the top of

the socket should be negative. If the positive and

negative connections have been reversed, the fuse

in the AddaBRAKE power cord will blow when the

cord is plugged into the 12-volt outlet.

1. Plugthe12-voltpowercordintothe12-voltoutlet,

andsecureitbypressingthecordlock(Figure11)into

the12-voltoutlet.

continued on next page

Figure 9

14

Plug in the power cord

continued from preceding page

Push the cord lock forward, into the 12-volt out-

let, to properly secure the 12-volt power cord. If the

cord lock is not over the 12-volt outlet, the power

cord may vibrate loose, causing a loss of power or

an intermittent power supply. AddaBRAKE will not

function without a continuous power supply.

2. Now,theredlightonthe12-voltpowercordshould

illuminate.(OneofthefourLEDsunderthe“Pressure”

buttonwillalsoilluminate,toindicatethecurrentbrake

pressuresetting.YouwilladjustthissettinginStepE

—“Setthebrakepressure.”)

Iftheredlightonthe12-voltpowercorddoesnot

illuminate,thereisnopower.

Somevehiclesonlyhavepowerattheoutletwhen

the engine is running. If there is no power, you can

installROADMASTER’soptional12-voltoutletkit(part

number9332).Wheninstalled,thisoutletkitwillprovide

powerevenwhentheengineisoff.

3. Whenthepowercordis pluggedin,theaircom-

pressorwillrununtiltheairreservoirisfilled.Waitfor

theairreservoirtofillbeforepressingthe“Test”button

(StepD,next).

Step D

Test and adjust positioning;

deplete the vacuum in the power brakes

Beforetowing,alwayspressthe“Test”buttondown,

thenreleaseit—AddaBRAKEwillcyclethepedalclamp

upanddownthreetimes.

This test cycle is necessary for two reasons: 1) to

ensurethatAddaBRAKEispositionedcorrectly;and2)

to deplete any stored vacuum in the towed vehicle’s

powerbrakesystem.

Always deplete the stored vacuum in the towed

vehicle’s power brake system before towing — press

the “Test” button down, then release it, to cycle the

pedal clamp up and down three times.

Depending on the make and model of the towed

vehicle, it may be necessary to repeat the test cycle

a second time.

If the vacuum is not released, AddaBRAKE will

apply excessive braking force when it is activated,

which will cause severe tire and/or brake system

damage to the towed vehicle.

DAY-TO-DAY OPERATION

Figure 11

1. Pressdownonthe“Test”button(Figure12),then

releaseit. AddaBRAKEwill cyclethe pedalclamp up

anddownthreetimes.

IfAddaBRAKEmovesexcessively,orinterfereswith

seat position controls, adjust its position. Check the

adjustableseatpadandreadjustit,ifnecessary.

If the adjustable seat pad is not properly posi-

tioned, AddaBRAKE can “climb” up the driver’s seat

— the rear of the box will rise up off the floor.

Unless AddaBRAKE is properly positioned, it will

not function at full capacity — the pedal clamp will

not apply the proper braking pressure against the

brake pedal.

Check the adjustable seat pad after the pedal

clamp has cycled during a test. If the rear of the

box has “climbed” the driver’s seat, readjust the

seat pad so that AddaBRAKE cannot “climb.”

15

Figure 12

Step E

Set the brake pressure

The brake pressure setting is the amount of force

AddaBRAKEwillapplyto thetowedvehicle’sbrakes.

Thesettingisbasedonweight—theweightofthetowed

vehicle,plustheweightofallitscontents.

Note: 1999 and newer Jeep Grand Cherokees are

set to 45 psi, regardless of the weight.

Refertothe“BrakePressureChart”(below)tofind

themaximumbrakepressuresettingforyourvehicle.

Initially, set brake pressure near (but not above) the

maximumrecommendedvalue.

Thedegreetowhichthissettingwillaffectthemo-

torhomewillvary,dependingonthesizeandweightof

the motorhome in comparison to the size and weight

of the towed vehicle. A sharp pull at the motorhome

may indicate that the brake pressure is set too high.

Or,evenifthepressureissetcorrectly,youmayprefer

tolowerthesettinguntilthetowedvehiclebrakeswith

lessforce.

Do not set brake pressure above the maximum

recommended value. If brake pressure is set above

the maximum, AddaBRAKE will apply excessive

force to the towed vehicle’s brake pedal, which will

cause tire and/or brake system damage, as well as

other consequential, non-warranty damage.

Conversely, do not lower the brake pressure set-

ting to the point that it negates the benefit of the

supplemental braking system. Insufficient brake

pressure will lengthen stopping distance, and may

also cause a loss of vehicular control.

Failure to follow these instructions may cause

property damage, personal injury or even death.

1. Pulloutontheregulatorcontrolknob(Figure13)to

DAY-TO-DAY OPERATION

Brake Pressure Chart

Weightof Maximum

towedvehicle recommended

andallitscontents pressuresetting

1,500-2,000pounds................................... 25psi

2,000-2,500pounds................................... 35psi

2,500-3,000pounds................................... 35psi

3,000-3,500pounds................................... 40psi

3,500-4,000pounds................................... 45psi

4,000-4,500pounds................................... 50psi

4,500-5,000pounds................................... 55psi

over5,000pounds..................................... 60psi

For Jeep Grand Cherokee…

Maximum

recommended

Towedvehicle pressuresetting

JeepGrandCherokee ............................... 45psi

(1999andnewer)

unlockit.

2. Then,pressandholdthe“Test”buttondown(Figure

13).Iftheairreservoirisnotcompletelyfilled,waitfor

theaircompressortofillthereservoir.

3. Next,turntheregulatorcontrolknobclockwiseto

increasethebrakingpressure,orcounterclockwiseto

decreasethebrakingpressure.

4. Whentheneedleonthepressuregaugematches

thepressuresettingyouhavechosen,releasethe“Test”

button.Then,pushtheregulatorcontrolknobdownto

lockitinplace.

Itisonlynecessarytosetthebrakingpressureonce

— after the pressure has been set, AddaBRAKE will

alwaysbrakewiththesameforce.

5. Tocheckthebrakepressure,pressandholdthe

“Test” button down. As the pedal clamp extends, the

needleonthegaugewillpointtotheselectedpressure

setting.

Step F

Connect the wiring harness;

test the break away system

1. Connect the AddaBRAKE wiring harness to the

breakawaywiringharness(two-prongconnectors)and

thebrakesignalwire(bulletconnectors).

2. Atthetowedvehicle,clipthesteelbreakawayca-

ble(Figure1)tothelargeringonthebreakawaypin

(Figure 1), then clip the other end of the steel break

awaycabletotherearofthemotorhome,closetothe

center.

continued on next page

Figure 13

16

DAY-TO-DAY OPERATION

Connect the wiring harness;

test the break away system

continued from preceding page

3. Periodically,testthebreakawaysystem—pullthe

breakawaypinoutofthebreakawayswitch.TheAdd-

aBRAKEpedalclampwillextendwhenthepinispulled.

Insert the pin back into the switch. The AddaBRAKE

pedalclampwillretract.

When connecting the break away system, always

check the following:

• Connectthecableattherearofthemotorhome,

close to the center. Connecting the cable toward

either side of the motorhome may cause the break

away pin to be pulled when the motorhome turns,

activating the break away system.

• Becertaintherearenoobstructionswhichwould

prevent the cable from pulling freely away from the

break away switch. Do not wrap the cable around

anything — doing so could keep the cable from pull-

ing the break away pin, preventing the system from

activating in a break away.

• Makesurethecableisthecorrectlength…

• The cable must be long enough to prevent

the break away pin from being pulled out

during normal towing — make certain there

is enough slack to allow for sharp turns. If

the cable is not long enough, the break away

system will activate even though the towed

vehicle has not detached.

• Thebreakawaycablemustbelongerthanthe

safety cables. This will prevent the break away

system from activating if a component of the

towing system has separated, but the towed

vehicle is still held by the safety cables.

• Make certain that the cable is not too long —

it should not hang down to the extent that it

may catch on obstructions, or drag on the

ground. This much slack could allow the cable

to be pulled inadvertently, activating the break

away system.

• Ifyouhaveatelescopingtowbar,allowenough

slack for the tow bar arms to be fully extend-

ed.

• Leave the break away pin in place, even when

the vehicle is not being towed. If the pin is not in

place when AddaBRAKE is connected, the break

away system will be activated — the air cylinder will

extend and will not retract.

Failure to follow these instructions may cause

property damage, personal injury or even death.

Step G

Connect the motorhome

monitor patch cord

Note: if both ends of the monitor wiring harness were

connected to open terminals on the electrical sockets,

the motorhome monitor patch cord is unnecessary. Re-

fer to Steps C and F under “Initial Installation.”

1. Atthetowedvehicle,connectamalebulletconnec-

toronthepatchcordtothefemalebulletconnectoron

themotorhomemonitorwiringharness.

Atthebackofthemotorhome,connecttheother

malebulletconnectoronthepatchcordtothefemale

connectoronthemotorhomemonitorwiringharness.

Allowenoughslacktopreventthepatchcordfrom

being pulled loose when the motorhome turns. If the

cordistoo long,wrap itaroundthe towedvehicle-to-

motorhomeelectricalcord.

Step H

Test the braking system

Note: the motorhome and towed vehicle must be

stationary for the system test, and ready for towing —

all components of the braking system must be properly

connected and receiving power. Then, according to the

manufacturer, make all adjustments necessary to pre-

pare the vehicle for towing. These adjustments may

include: turning the ignition key to the “tow” position;

pulling fuses; disconnecting the battery; and setting

the transmission to a particular gear or in a particular

sequence.

Refer to the owner’s manual, or call the dealership

or the manufacturer for vehicle-specific information.

1.Confirmtheproperoperationofthesupplemental

braking system: depress and hold the motorhome’s

brakepedaldown.TheAddaBRAKEaircylindershaft

and pedal clamp will extend (after approximately two

seconds).Then,releasethebrakepedal.Atthetowed

vehicle, the AddaBRAKE air cylinder shaft and pedal

clampwillretract.

2. Confirmthatthemotorhomemonitorisfunctioning:

theLEDwillilluminateafterthemotorhome’sbrakeped-

alisdepressed(afterapproximatelytwoseconds),and

stopilluminatingwhenthebrakepedalisreleased.

If the LED does not illuminate…

…at any time when the motorhome brake pedal

is depressed, it may indicate that AddaBRAKE is

not functioning. If AddaBRAKE is not functioning,

continued on next page

17

Responding to an audio alert

If, for any reason, AddaBRAKE is depressing the

towedvehicle’s brake pedalcontinuously for approxi-

mately20seconds,themotorhomemonitorwillsignal

youwithanaudioalert.

In addition to the audio alert, the monitor LED will

beilluminatedcontinuously.

Stopimmediatelyafteranaudioalertfromthemoni-

tor.TheaudioalertandilluminatedLEDareindicating

thatthetowedvehicle’sbrakepedalisbeingdepressed.

Significantbrakesystemdamagetothetowedvehicle,

aswellasotherconsequentialdamage,mayresult.

Identifyandcorrectthecauseoftheaudioalertbe-

foreusingAddaBRAKE.

If the monitor signals you with an audio alert,

stop immediately. Identify and correct the cause of

the audio alert before using AddaBRAKE.

Failure to respond to an audio alert, as indicated

above, may cause property damage, personal injury

or even death.

PROTECTION MODES

Extended braking protection

Toprotectthetowedvehicle’sbrakes,AddaBRAKE

willautomaticallyreleasebrakingpressureafteranex-

tendedperiodofcontinuousbraking.

Toregainsupplementalbrakinginthetowedvehicle,

releaseanddepressthemotorhome’sbrakepedal.

Note: activating the exhaust brakes in some motor-

homes may also illuminate the motorhome brake lights.

If this is the case, AddaBRAKE will be activated with the

exhaust brakes, and will automatically release braking

pressure after an extended period of continuous brak-

ing.

To regain supplemental braking in the towed vehicle,

and use an exhaust brake system of this type, cycle

the exhaust brakes on and off.

AddaBRAKE has two built-in safeguards to protect the towed vehicle’s brakes. These protection modes are

describedbelow.

DAY-TO-DAY OPERATION

Test the braking system

continued from preceding page

it will not brake the towed vehicle in tandem with the

motorhome, which will lengthen stopping distance,

and may also cause a loss of vehicular control.

Refer to the ‘Troubleshooting’ section (under

‘Electrical’) to identify and correct the cause of the

malfunction, then test to ensure that the LED and

AddaBRAKE are both operating properly.

Failure to follow these instructions may cause

property damage, personal injury or even death.

3. Confirmtheproperoperationoftheextendedbrak-

ing mode: depress and hold the motorhome’s brake

pedal down. The AddaBRAKE air cylinder shaft and

pedal clamp will extend. After approximately 15 sec-

onds, the air cylinder shaft and pedal clamp will re-

tract.

4. Attheinitialinstallation,andperiodicallythereafter,

confirmtheproperoperationoftheaudioalert:depress

andholdthetowedvehicle’sbrakepedal down.After

approximately20seconds,themotorhomemonitorwill

activatetheaudioalert.(Tocanceltheaudioalert,re-

leasethetowedvehicle’sbrakepedal.)

5. Attheinitialinstallation,andperiodicallythereafter,

confirmthatthemotorhometurnsignalsdonotactivate

AddaBRAKE.

An incorrect flasher speed may activate Adda-

BRAKE unnecessarily, causing excessive brake

wear or other consequential, non-warranty damage.

If the turn signals activate AddaBRAKE, check

the turn signal flasher rating — it may be inadequate

for the motorhome-towed vehicle combination. If

this is the case, replace the flasher with one rated

at or above the number of bulbs in the motorhome-

towed vehicle combination.

18

Table of contents

Other Roadmaster Diagnostic Equipment manuals

Popular Diagnostic Equipment manuals by other brands

Launch

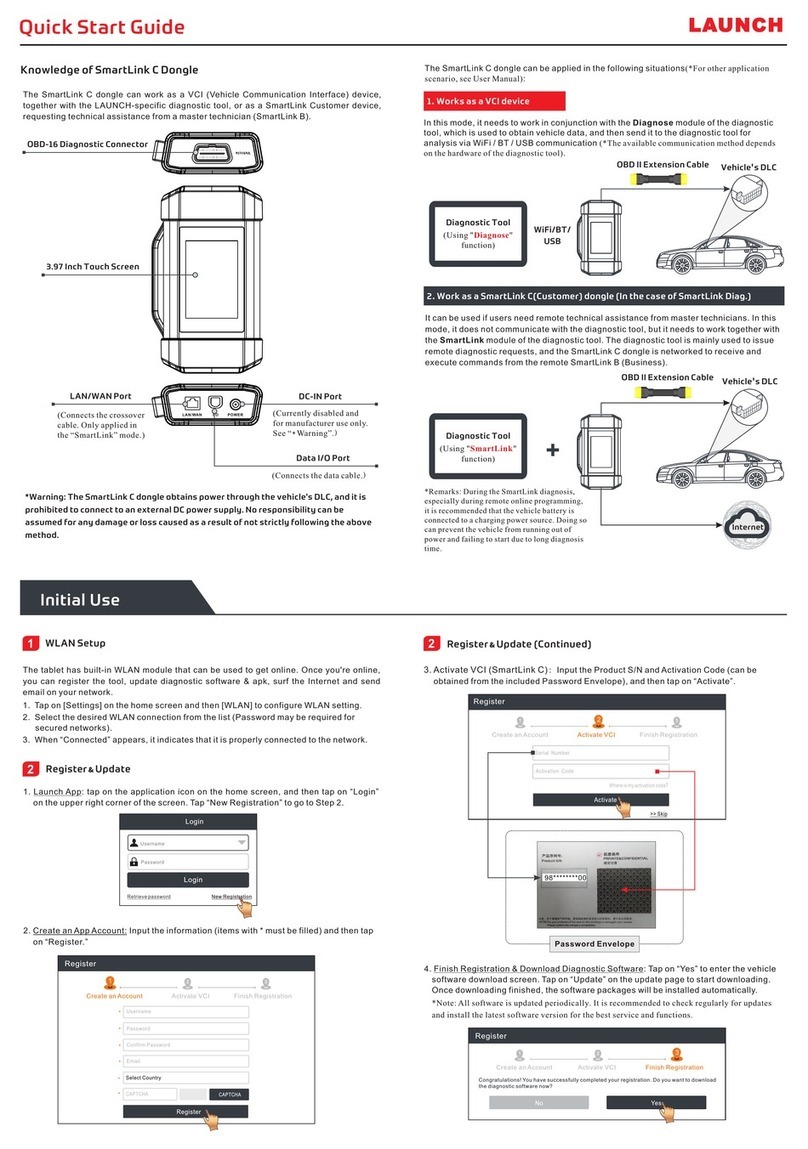

Launch SmartLink C Dongle quick start guide

Hella Gutmann

Hella Gutmann MT-HV operating instructions

Hella Gutmann

Hella Gutmann macsRemote operating instructions

Autel

Autel OTOFIX D1 Pro manual

VOLTCRAFT

VOLTCRAFT BS-200XW operating instructions

JT Innovations

JT Innovations Shift Light Mk2 user guide