over and hit the knives.

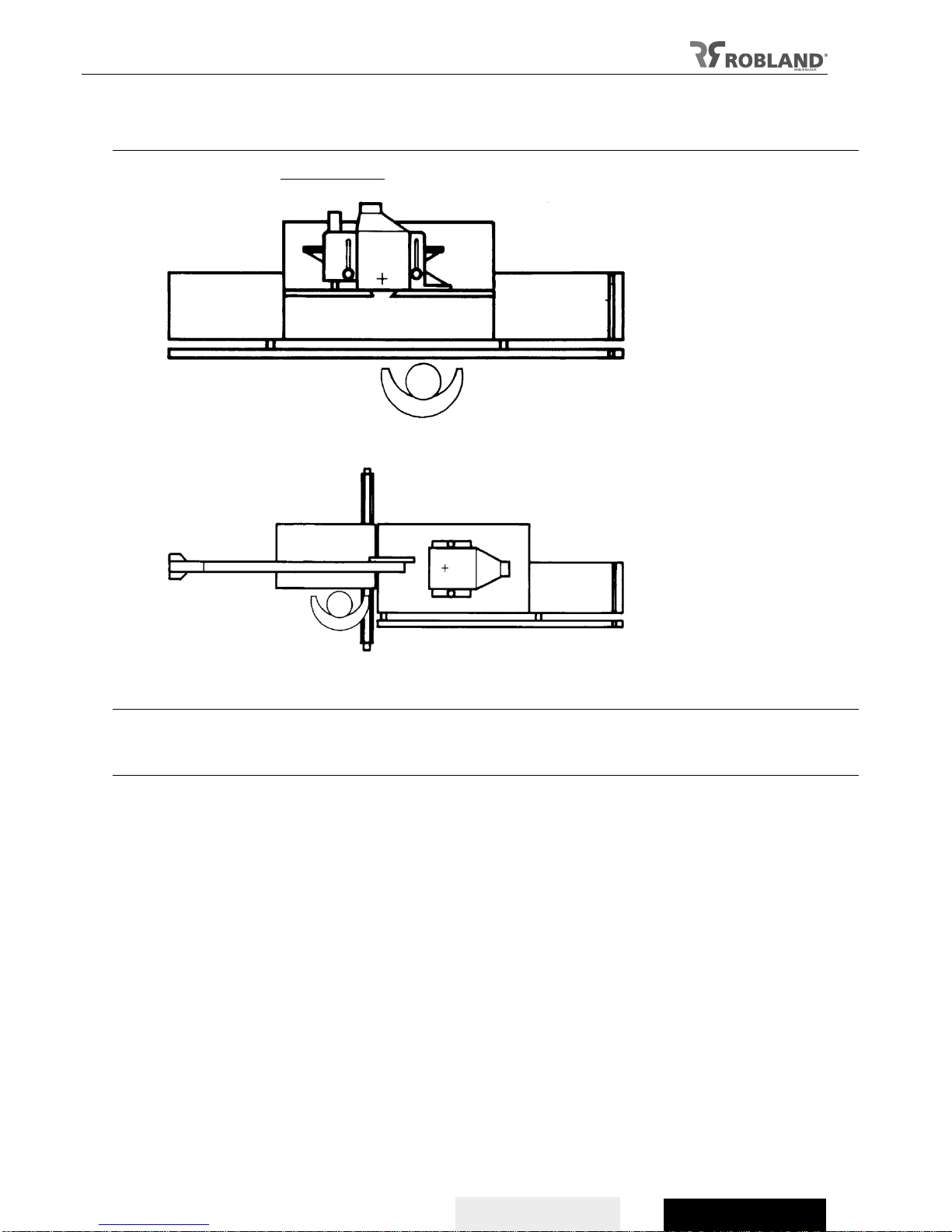

Using a power feeder can prevent most serious accidents involving hands. Such feeders easily are

adjusted and adapted to the size of the pieces.

When no power feeder is used, the wood pushers have to be used, the horizontal and vertical springs

making a tunnel where the piece can slide in. This pusher, together with other safety equipment,

reduces the gap between the cutting tool and the guide fences.

Using the spindle fence when the total length of the machine has to be

machined

In most cases a straight guard fence is used. In this way the pieces can be guided in the angle made

by the table and the fence. The vertical and horizontal pushers can be placed in such a way that a

tunnel is formed in which the first piece can be pushed. The second piece is then used to push the

first, the final piece has to be pushed forward with a wood pusher.

Special blocks have to be used relative to the dimensions of the work piece.

When working thin panels, only the top of the spring has to be used, on condition the thickness

matches.

On a spindle-moulder, the distance between the extremities of the spindle guard fences must be large

enough to leave enough space for the cutter block. Thus the knives, the cutter block and the spindle

shaft may be exposed and the extremity of the piece may come in contact with the nose of the exit

guard fence.

These risks can be avoided by using a false fence between the spindle guard fences, thus limiting the

opening between them.

Using the spindle guard fence when only a part of the piece is machined

When using the spindle fence between 2 stops fixed onto the machine table or fences, only a part of

the work piece is machined. By doing so, the cutting tool starts machining the work piece in the full

section of the wood and doesn't start at the front, this way the cutting action is more gradual and less

severe, and the cutting action is stopped before the workpiece end is reached. This action is very

dangerous and needs special attention and care.

A stop solidly fixed at the front and back has to be used (see the example used further in this manual).

A piece may only be guided by hand when it is sufficiently large. In all other cases a gauge or a

support with protection has to be used in order to avoid serious accidents. By means of the gauge, the

piece can quickly and precisely be put in place and firmly be held there. A quick clamping system,

working with tumblers or cams, is the most practical to hold the piece. When front and backstops are

fixed to the spindle guard fence or to the table, a better control of the gauge is possible.

Working with the ring guard

When working with the ring guard, a support has to be used, unless a certain process doesn't allow

this, i.e. when the work piece is too large or too small, or when too difficult to machine it cannot be

held in the support without danger. The final shape is obtained by holding the gauge against a

guidance bearing which is fixed to the spindle while the piece is held against the tool. The gauge can

be part of the support.

Chamfering

When chamfer7ing a solid support or a tilt adjustable spindle, a guard fence has to be used. A wood-

pusher has to be used for the final part of the machining.

Working in the direction of the tools

It is extremely dangerous to work in the direction of the tools, as the operator cannot exert force to

resist the strong movement of the piece when the tool comes into contact. Working in the direction of

the tools is forbidden, even when a support is used.

Other machining

For other types of work, e.g. tenoning, special gauges or supports can be used in order to avoid

accidents.

The following safety accessories can be used to help the operator during his work:

- supports,

- wood pushers,

- power feeders,

- rollers,

- stops.

Reasons for tool rupture

Following reasons may lead to a tool rupture: