Installation Instructions

Original Instructions

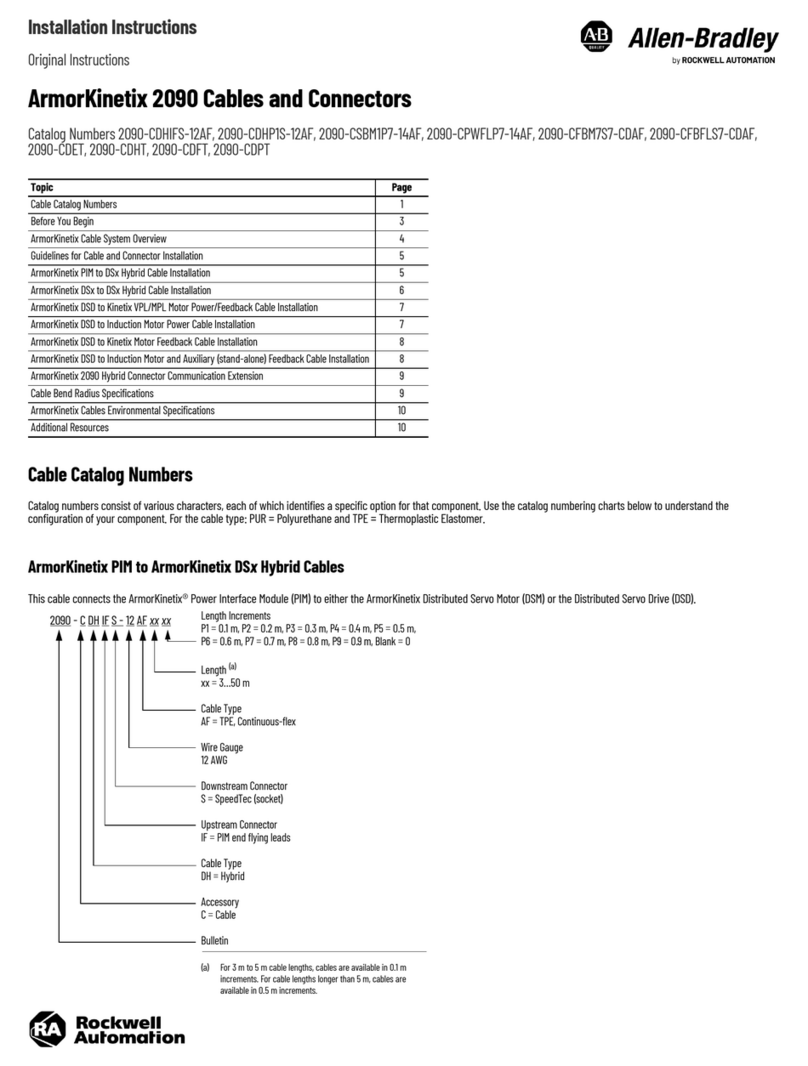

Build Your Own Kinetix TLP Motor Cables

Catalog Numbers

2090-KTPC-MA-AA, 2090-KTPC-MA-AE, 2090-KTFB-MA-AA, 2090-KTFB-MA-AE, 2090-KTBK-MB-AA, 2090-KTBK-MB-AE, 2090-KTFB-MF-AA,

2090-KTFB-MF-AE, 2090-KTPC-MC-AA, 2090-KTPC-MC-AE, 2090-KTPC-MD-AA, 2090-KTPC-MD-AE, 2090-KTPC-ME-AA, 2090-KTPC-ME-AE

For reference, see Kinetix Motion Accessories Specifications Technical Data, publication KNX-TD004, for Kinetix TLP motor and cable combinations and Kinetix TLP motor

power and feedback cable specifications.

Summary of Changes

This manual contains new and updated information as indicated in the following table.

Before You Begin

Remove all packing material from within and around the item. After unpacking, verify the catalog number against the purchase order, and visually inspect each connector

for damage. If necessary, notify the carrier of any shipping damage immediately.

Topic Page

Before You Begin 1

Wiring Connectors 2

Rectangular Connectors 3

Military-style Connectors 8

Catalog Number Descriptions 12

Additional Resources 12

Topic Page

Updated figures with enhancements to help you understand how the kits are assembled. Throughout

Added Military-style Power/Brake Connector (extension) Cable Examples. 9

Added Ring Lug Specifications. 9

Added Catalog Number Descriptions. 12

ATTENTION: Arcing or unexpected motion can occur if the power, brake, or feedback cables are connected or disconnected while power is applied.

Always remove power to the servo drive before connecting or disconnecting cables at the drive or at the motor.

ATTENTION: To avoid the hazard of electrical shock, make sure that shielded power cables are grounded at a minimum of one point. To help prevent

the build-up of electrical energy, factory-supplied power cables use one of these grounding techniques:

• The overall shield is bonded to the connector housing.

• A section of the overall shield is exposed for connection to ground.

• The overall shield is connected to a ground wire.

If the exposed cable braid or a ground wire is present, connect it to the power cable clamp, housing, or another suitable chassis ground on the drive.

ATTENTION: Do not tightly gather or coil the excess length of a power cable. Heat is generated within a cable whenever power is applied. Always

position a power cable so it can freely dissipate any heat. A power cable must not be coiled, except for temporary use when building or testing a

machine. If you temporarily coil a power cable, you must also derate the cable to meet local code or follow an authoritative directive, such as

Engineering Section 310.15(C) of the NEC Handbook.

IMPORTANT The following factors must be considered when selecting bulk cable.

• Power cables must be rated to voltage higher than the system voltages at all operating conditions.

• Cable conductor current carrying capacity (after all applicable deratings) must be ≥ the connected motor continuous rated current.

• Cables must meet all local and global regulatory requirements.

• Cable must have overall shield to meet the applicable electromagnetic radiation/emission requirements.