Safety Instructions

Special Conditions for Safe Use

Harmonized/Designated Standards

Conformed To (800G “-EX” Assembled Station)

Assemble, Install, and Commission

GeneralAssembly

Plastic Cable Gland Installation

WARNING:

For gas and dust installations: Potential electrostatic

charging hazard. Clean only with anti-static cloths.

• EN 60079-0 • EN 60079-1 • EN 60079-7 • EN 60079-31

• IEC 60079-0 • IEC 60079-1 • IEC 60079-7 • IEC 60079-31

ATTENTION:Risk of serious injury due to incorrect assembly,

installation, and commissioning.

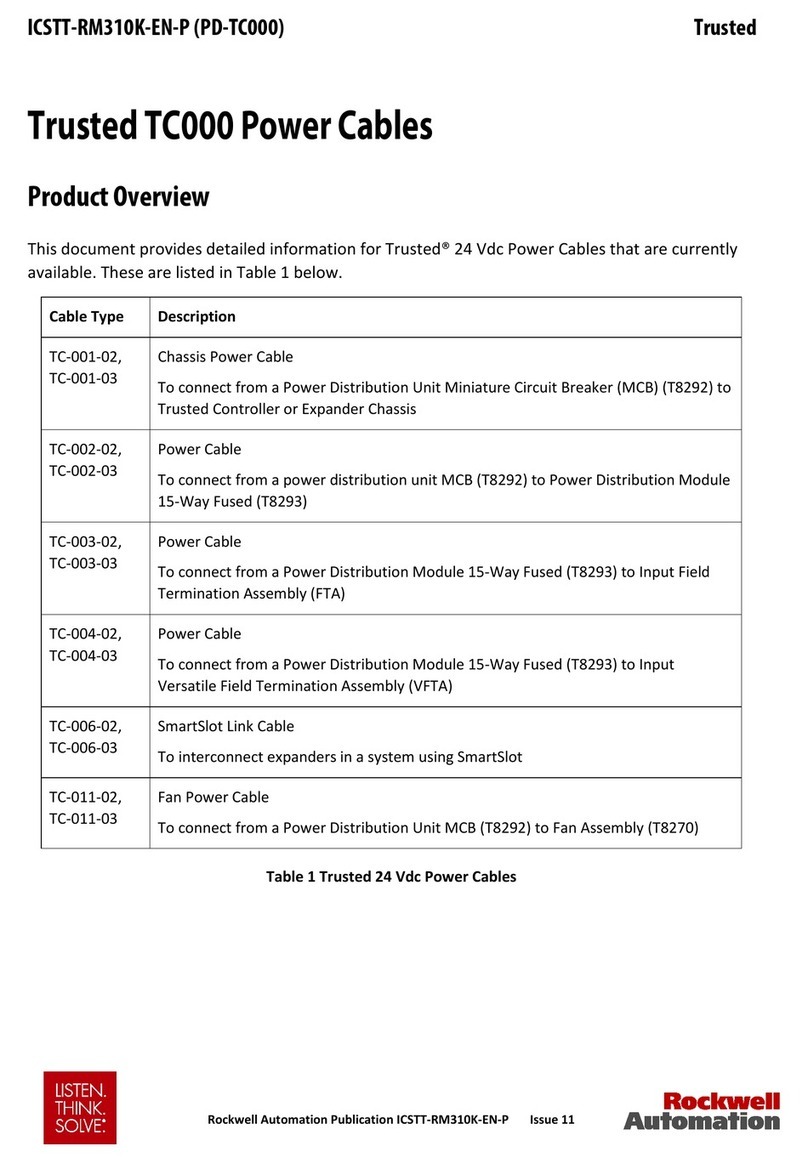

Earth Bracket 0.7…1.0 N•m

(6…9 lb•in)

Cable

Gland

Improper installation can cause malfunctioning and the loss of

explosion protection.

Cable glands can only be used within the specied ambient

temperature range and must be installed in a manner that maintains the

specied ingress protection raiting.

Use in areas other than those areas specied or the modication of the

product by anyone other than the manufacturer is not permitted and

exempts Rockwell Automation from liability for defects and any

further liability.

The applicable statutory rules and other binding directives that relate

to workplace safety, accident prevention, and environmental

protection must be observed.

Before you commission or restart operator, check compliance with all

applicable laws and directives.

All cable gland kits can only be used if they are in a clean and

undamaged condition. Do not modify these components in any way.

The cable glands must be mounted at the electrical apparatus in a way

that helps prevent accidental rotation and loosening. The cable glands

are only suitable for xed installations. Cables must be eectively

clamped to help prevent pulling or twisting.

The certicate does not cover hazards that come from environmental

conditions dierent from the hazards clearly and precisely indicated in

EN 60079-0 Clause 1.

•Only qualied personnel are allowed to assemble, disassemble,

install, and commission the device.

•Protect devices against mechanical damage or electrostatic

discharge.

•Use suitable tools and install cable rmly.

•Use cable that is rated with an appropriate temperature range

siutable for the application.

•In appropriate enclosures with “Ex e” increased safety type of

protection. The clearance and creepage distances under IEC/

EN60079-7 Clauses 4.3 and 4.4 must be observed.

•In an enclosure that corresponds to another approved type of

protection that is specied in IEC/EN 60079-0 Clause 1.

•Within an 800G “-EX” assembled station that has been

drilled/tapped at the manufacturing facility. Field

modication of 800G “-EX” enclosures is not permitted and

voids all certications and hazardous location ratings.

In hazardous areas, the cable glands must be used in the following ways:

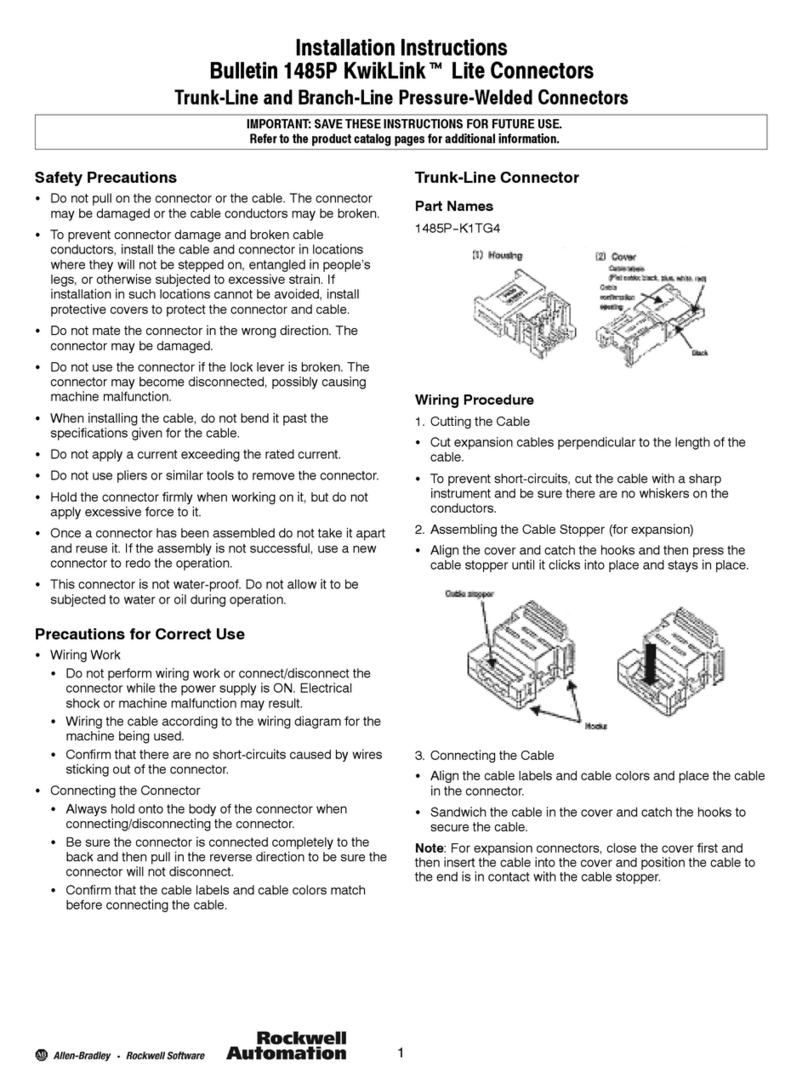

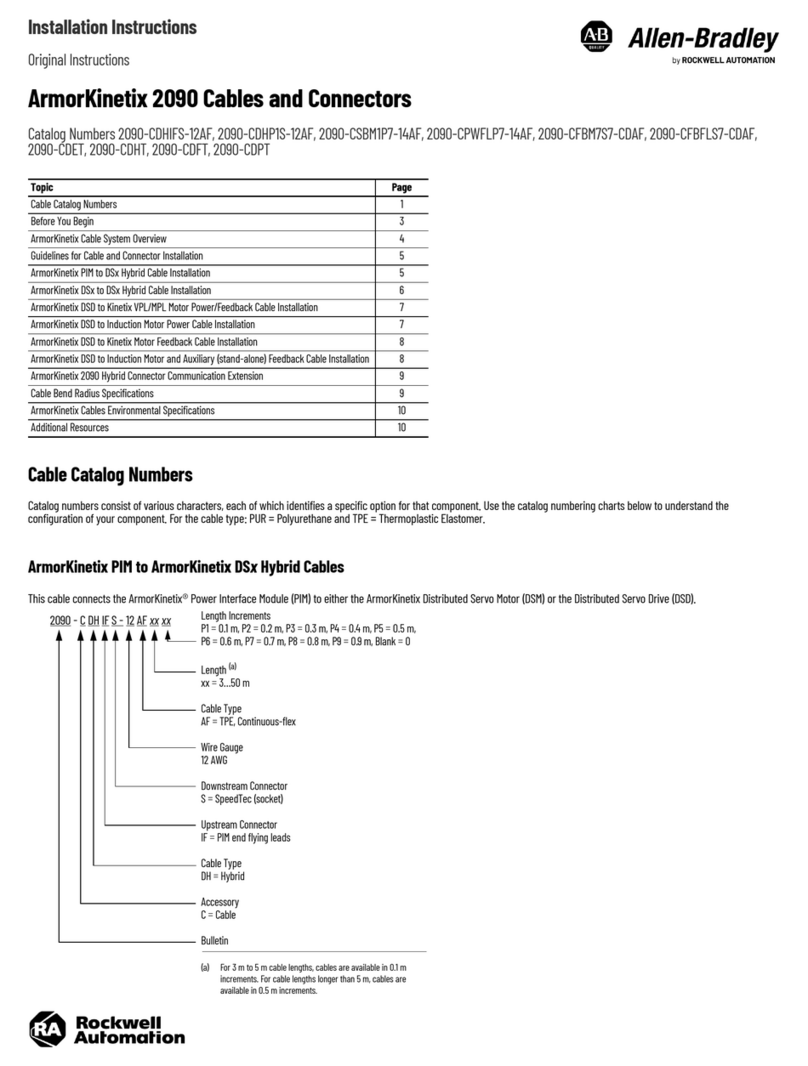

Follow these steps to install the plastic cable gland:

1. Verify that the cable gland and earth bracket are intact with no

physical damage.

2. Thread the cable gland onto the appropriately sized opening

on the top or bottom of the Bulletin 800G“-EX” enclosure,

verifying that the red sealing washer is between the cable gland

body and the 800G “-EX” enclosure.

3. Tighten the gland to the following torque range:

• M20 cable glands - 1.5...2.5 N•m(13.3...22.1 lb•in)

• M25 cable glands - 2.0...3.0 N•m(17.7...26.6 lb•in)

4. Remove the red dust plug and route the eld cable through the

seal of the cable gland. Adjust the free length of the cable so it

can connect to all back-of-panel components inside of the

enclosure.

5. Position the earth bracket where the cable gland is installed

(top or bottom) and push the earth bracket between the rib

and inside wall of the enclosure.

6. Open the terminal cages of the earth bracket and insert the

conductors that must be grounded.

7. Tighten the earth bracket

terminals to a torque range

of 0.7...1.0 N•m (6...9

lb•in).

8. Tighten the cable gland

cap to the following torque

range:

• M20 cable glands -

5.5...6.5 N•m (48.7...57.5 lb•in)

• M25 cable glands - 8.0...10.0 N•m (70.8...88.5 lb•in)

PN-534159 DIR 10004603657 (Version 01)

Publication 800G-IN006B-EN-P - May 2022

Installation instruction for BUL. 800G, Cable Gland Kits

2/4