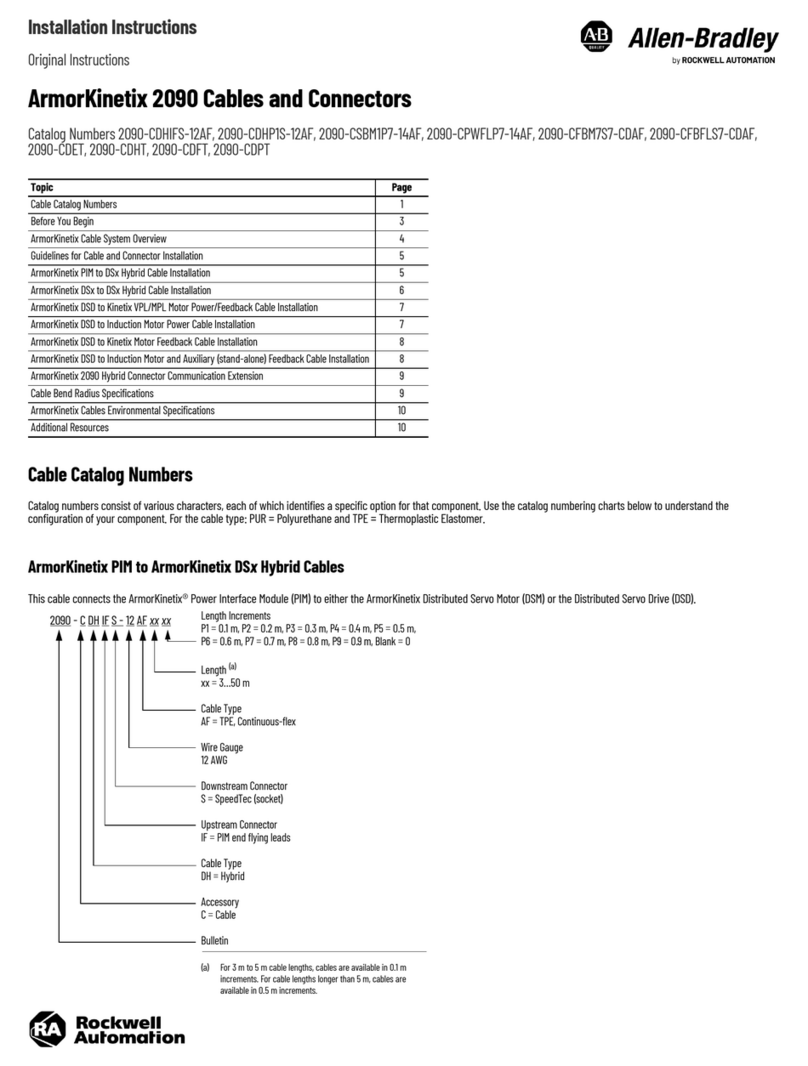

2Rockwell Automation Publication 2090-IN046B-EN-P - August 2020

2090-Series Kinetix TLP Power and Feedback Cables Installation Instructions

Before You Begin

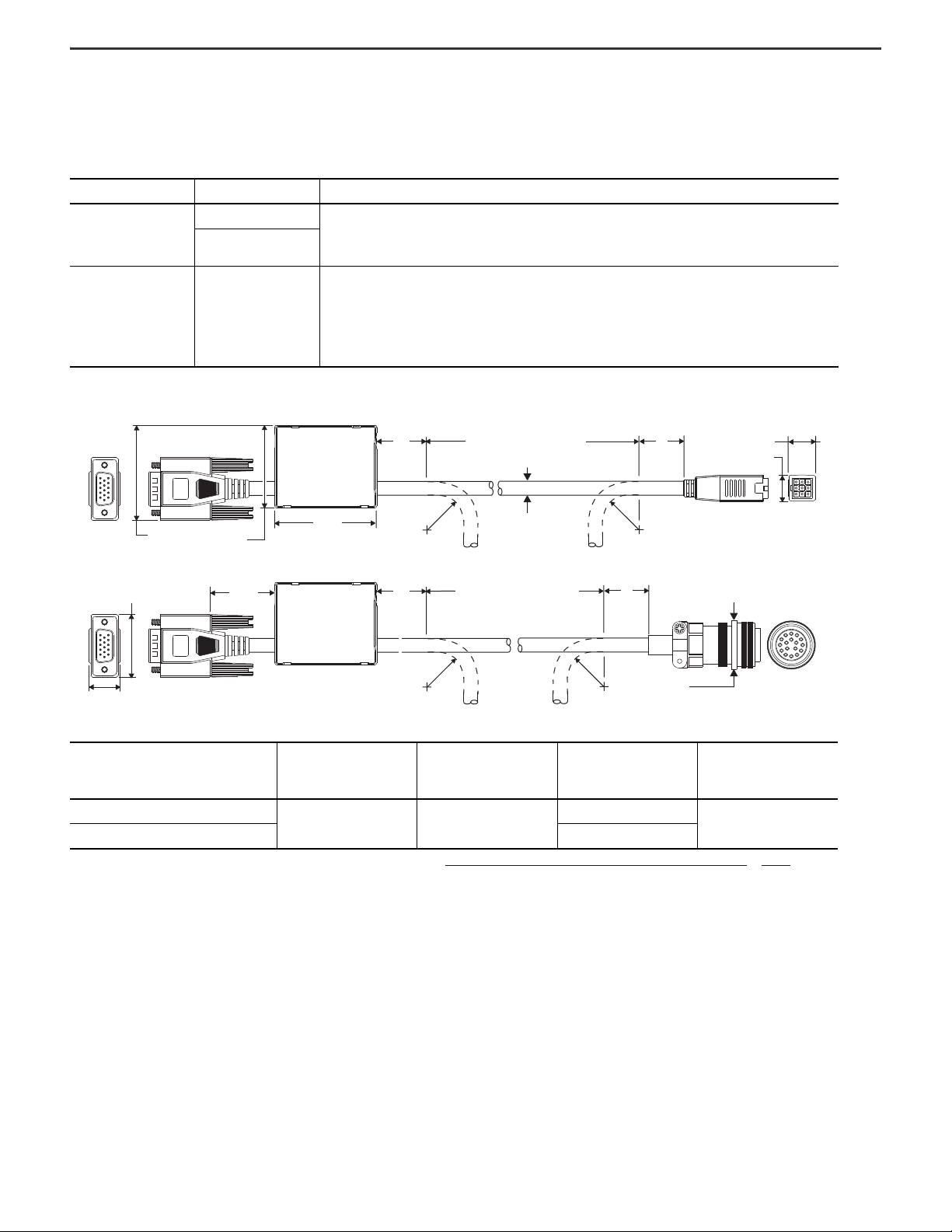

Remove all packing material from within and around the item. After unpacking, verify the catalog number against the purchase order and visually inspect the cable and

each connector for damage. If necessary, notify the carrier of any shipping damage immediately.

Cables are stored and shipped in a coil. Cables retain this shape until you straighten the cable. To straighten a cable, hang a short cable from its mid-point or lay a long

cable on the floor in a straight line. Any coiling that remains in the cable is straightened out within the next 24 hours. This practice makes the cable easier to install.

ATTENTION: Observe the following precautions when installing cables in a servo system. Failure to observe these safety notices can result

in personal injury or damage to the motor and equipment.

• Arcing or unexpected motion can occur if the power/brake or feedback cables are connected or disconnected while power is applied to the

drive. Always remove power to the servo drive before connecting or disconnecting cables at the drive or at the motor.

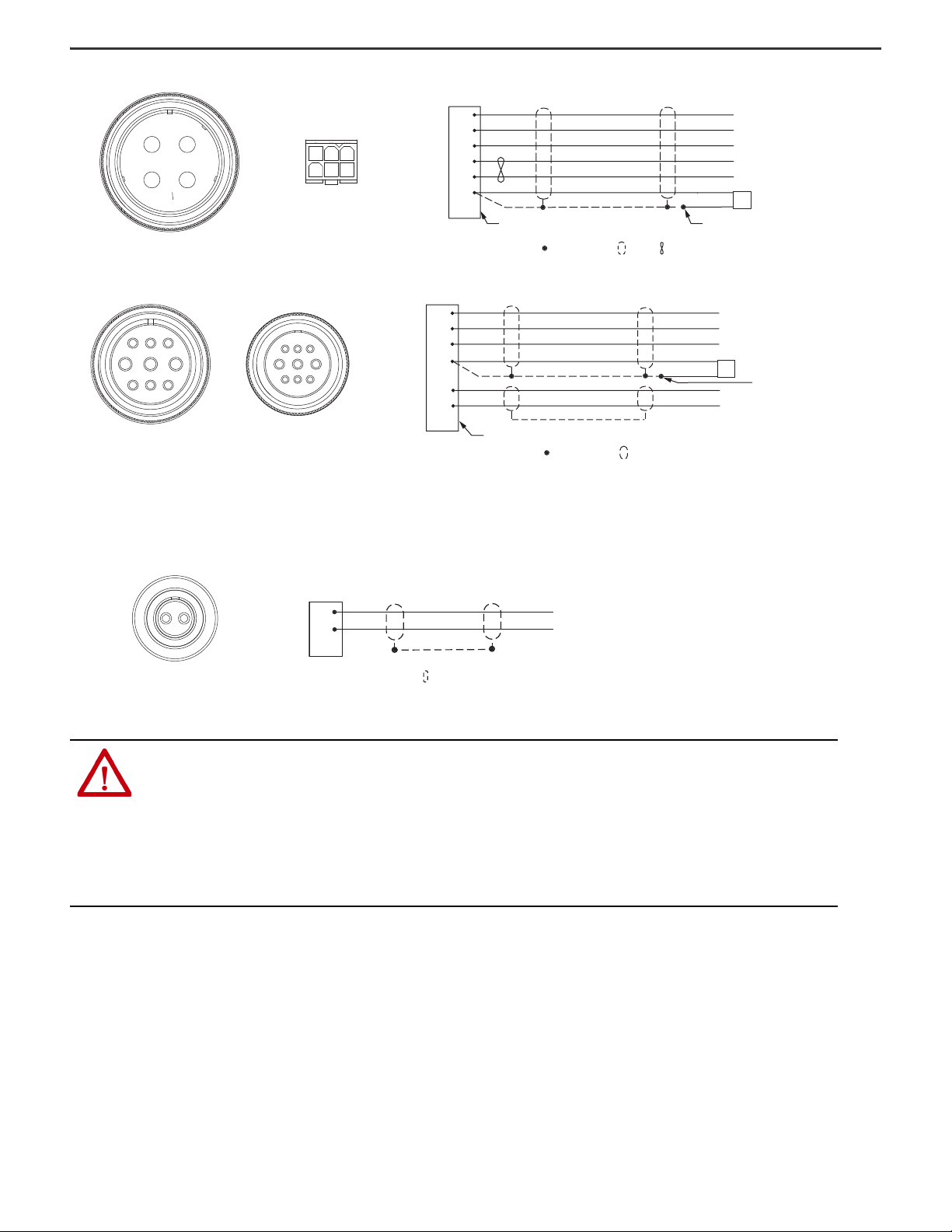

• To avoid electrical shock, make sure that shielded power cables are grounded at a minimum of one point. To prevent the build-up of

electrical energy, factory-supplied power cables use one of these grounding techniques:

– The overall shield is bonded to the connector housing.

– A section of the overall shield is exposed for connection to ground.

– The overall shield is connected to a ground wire.

If the exposed cable braid or a ground wire is present, connect it to the power cable clamp, housing, or another suitable chassis ground on the drive.

• The maximum cable length between the drive and the motor varies, depending on the application, but never exceeds 50 m (164 ft) for Kinetix®

5100 drives, See Kinetix Servo Drives Specifications, publication KNX-TD003, for additional information.

• Do not tightly gather or coil the excess length of a power cable. Heat is generated within a cable whenever power is applied. Always position a

power cable so it can freely dissipate heat.

– Do not coil a power cable except for temporary use when building or testing a machine. If you temporarily coil a power cable, you must

also derate the cable to meet local code or follow an authoritative directive, such as Engineering Section 310.15(C) of the NEC Handbook.

• The examples in this publication show all available connections. Some connections are not used for specific installations. See your drive

installation instructions or user manual for recommended wire trim lengths and wiring examples for your drive and motor application.

– Do not connect unused wires. Trim and finish unused wires to prevent accidental contact with other wires or wire shields, or with a

ground connection.

IMPORTANT Standard (non-flex) cables can be bent or reformed during installation and maintenance. Continuous-flex cables can be flexed

repeatedly within a specified bend radius when properly installed.

Do not use standard cables in a continuous-flex operation.