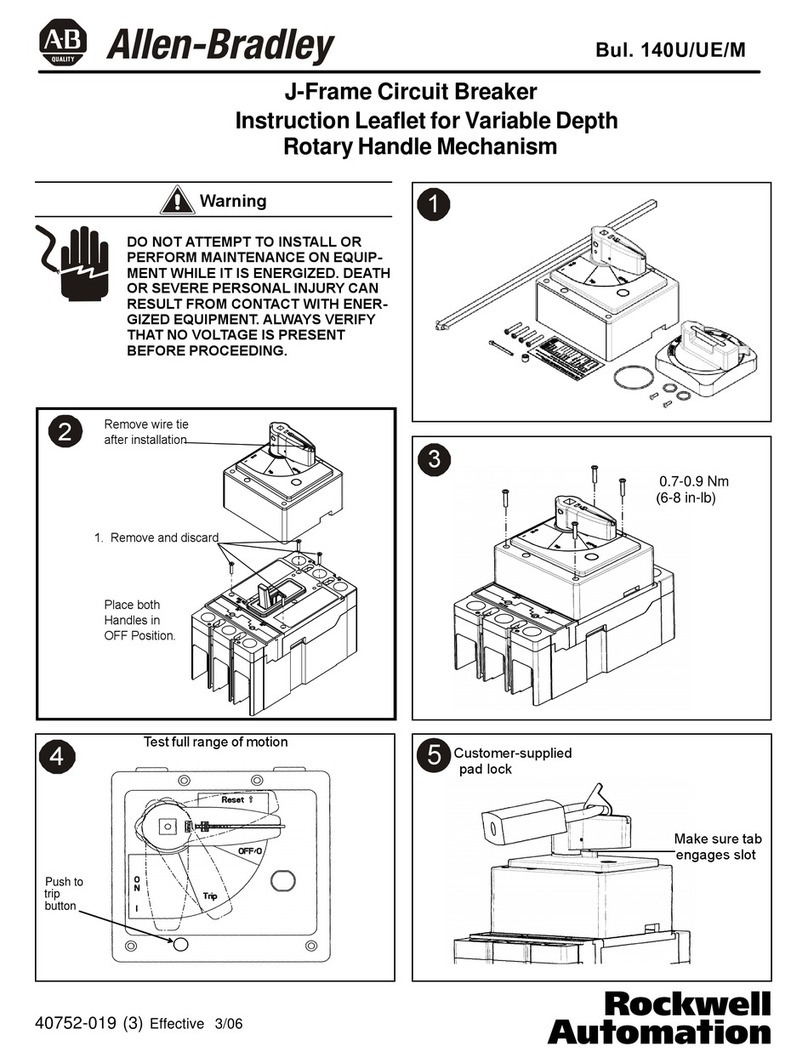

2

-

2.

Dependingon theequipment configuration, the

circuit breakercan be mounted usingdifferent styles

of

hardware. The following steps describe how

to

mount

the circuit breakerusingstandard hardware. When

special hardwareisneeded (for example,with the

electricaloperator), the instruction leafletdescribingthe

accessory

also

describesthespecial mounting

arrangements.

Note:

Beforemountingthe circuit breaker, check if the

termination devicesshould be installedfirst. See termi

-

nationsinstructions.

2

-

3.

To

mountthe circuit breaker,performthefollowing

steps:

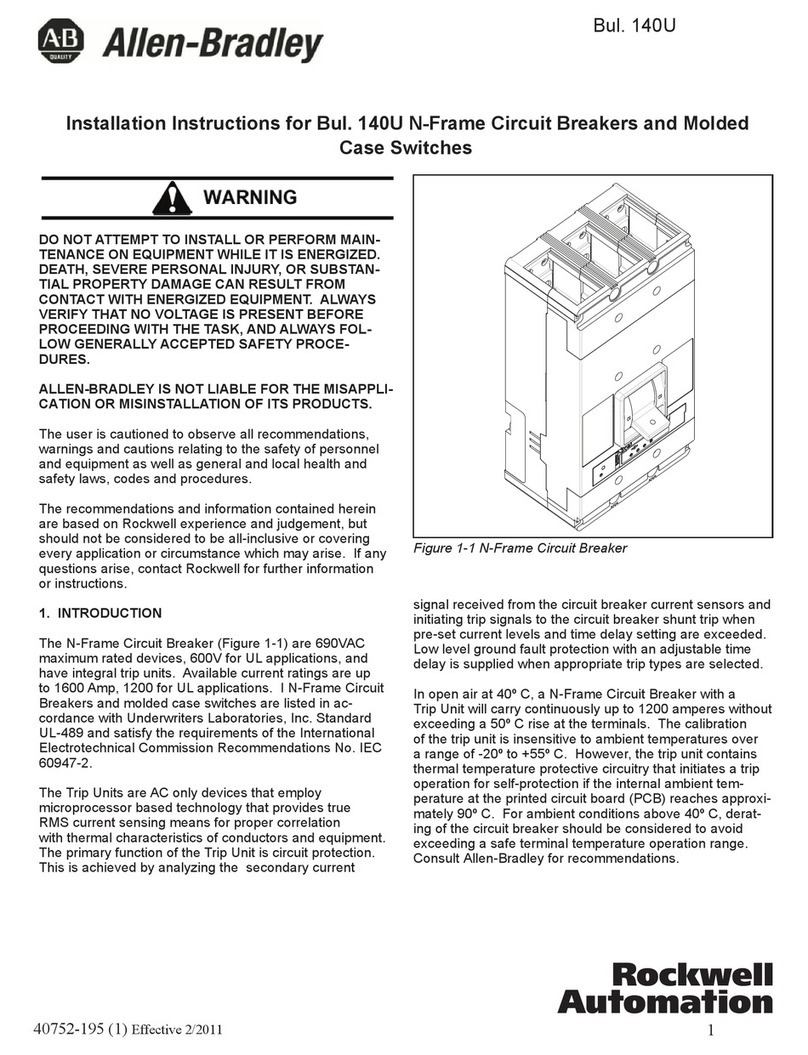

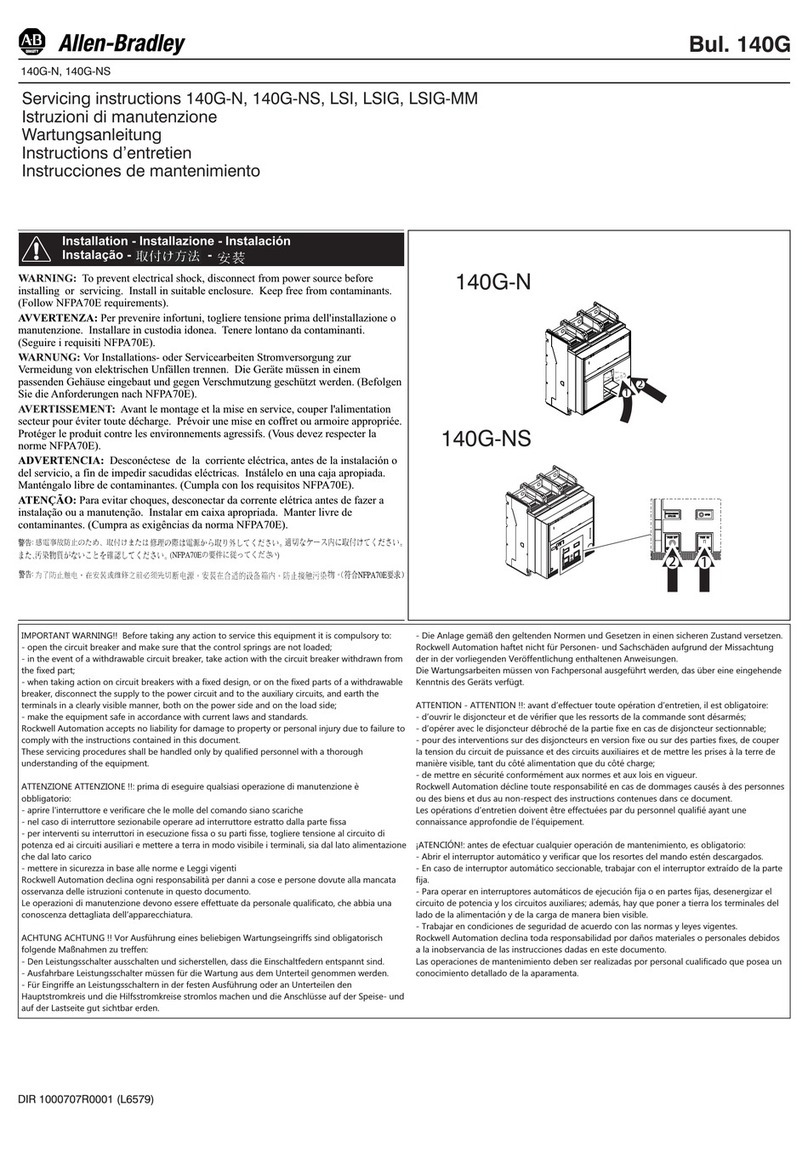

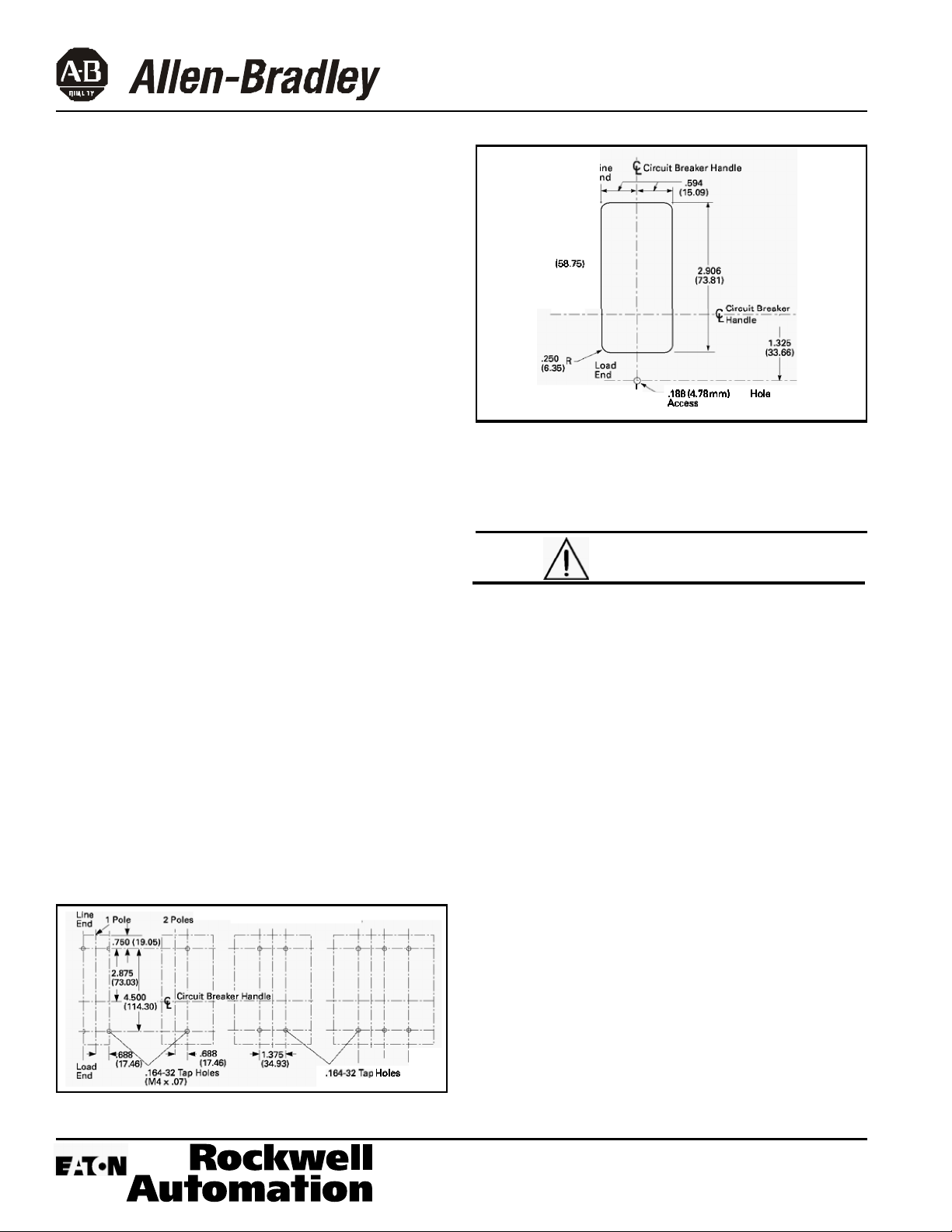

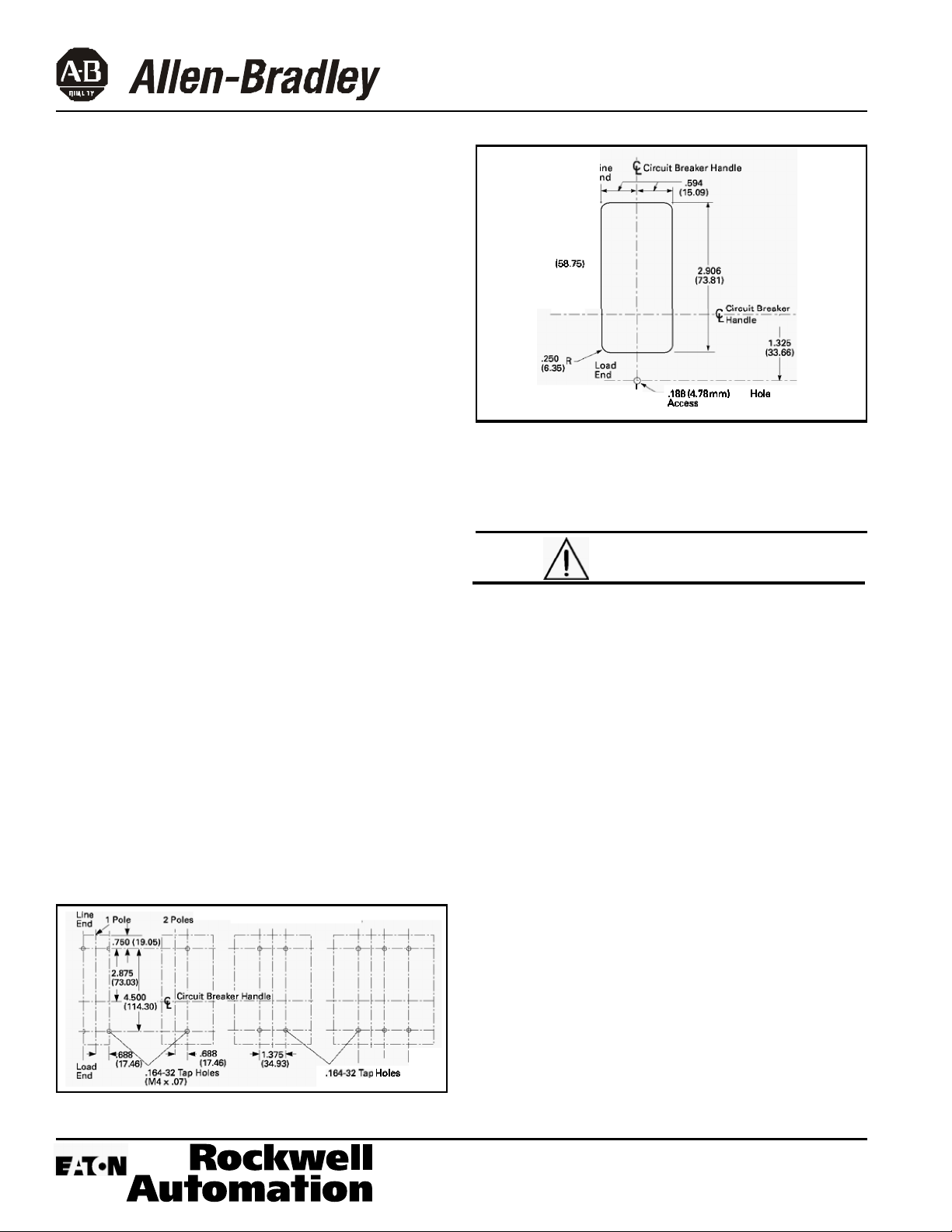

a. For individual mountingpanels, make sure that

mountingpanelis predrilled using boltdrilling plan

(Fig.

2

-

1).

Fordeadfront cover applications

make

sure panelcover iscut out to

correct escutcheondimensions (Fig. 2-2)

).

T

2913

158.751

I

'

,188

(478

mm)

Dia.

Hde

for

Access

to

Push

-

to-Trip

Fig.

2

-

2. Circuit

Breaker

Escutcheon Dimensions

2

-

4.

If

anoptional terminal endcover isto beinstalled

with thecircuit breaker (usually line end only), it must be

positionedbeforecable is connectedtoterminals.

b.

If

circuit breakerincludesfactory installedinternal

accessories, makesure accessorywiring can be

reachedwhen the circuit breaker is mounted.

c. Positioncircuit breaker on mountingsurface.

d.

Installmountingscrews, washers, and nuts.Tighten

screws firmly, but do not exceed

28

pound

-

inches

(3.16 N.m.).

N.m.).

3

Poles

4

Poles

.164-32Tap

Holes

(M4

x

.07)

WHEN ALUMINUM CONDUCTORSARE USED,

THE

APPLICATION OF

A SUITABLE

JOINT

COMPOUND

IS

RECOMMENDED

TO

REDUCE

THE

POSSIBILITY

OF

TERMINALOVERHEATING.TERMINALOVERHEATING

CAN

CAUSE NUISANCE

TRIPPING

AND DAMAGE

TO

THE

CIRCUIT

BREAKER.

2

-

5.

After mountingthecircuit breaker, line and load

terminals andaccessory leads should be connected.

(See accessoryschematic diagram on side of circuit

breaker.

)

Note:

If

terminalshield

or

interphase barriersare

to

be

installedon the circuit breaker,installthem afterthe

terminals are connected.

2

-

6.

If

required, installterminalshieldon circuit breaker

coverwith mountingscrews provided.

2

-

7.

If

required, installan interphase barrier by sliding

barrierintodovetail grooves betweenterminals.

2

-

8.

After the circuit breakeris installed, check all

mounting hardwareand terminalconnectinghardware

for correct

torque loading.

Torque values for line/load

terminals are given inTables

2

-

1

and

2

-

2

andon the

circuit breakernameplate.

Fig,

2

-

1. Circuit Breaker Mounting Bolt Drilling Plans

40752-162(1)

Effective

7/07

CAUTION