6

40752-195 (1) 2/2011

VOLTAGE IN ENERGIZED EQUIPMENT CAN CAUSE

DEATH OR SEVERE PERSONAL INJURY. BEFORE

MOUNTING THE CIRCUIT BREAKER IN AN ELECTRI-

CAL SYSTEM MAKE SURE THERE IS NO VOLTAGE

PRESENT WHERE WORK IS PERFORMED. SPECIAL

ATTENTION SHOULD BE PAID TO REVERSE FEED AP-

PLICATIONS TO ENSURE NO VOLTAGE IS PRESENT.

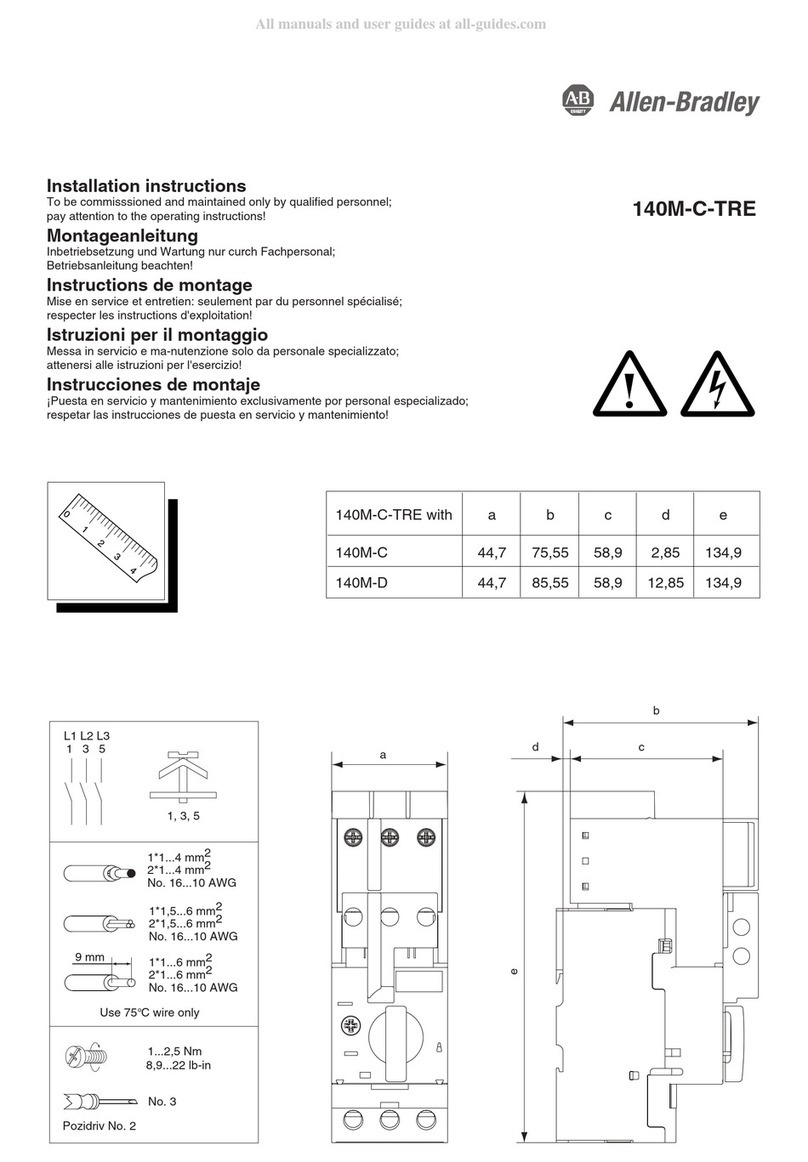

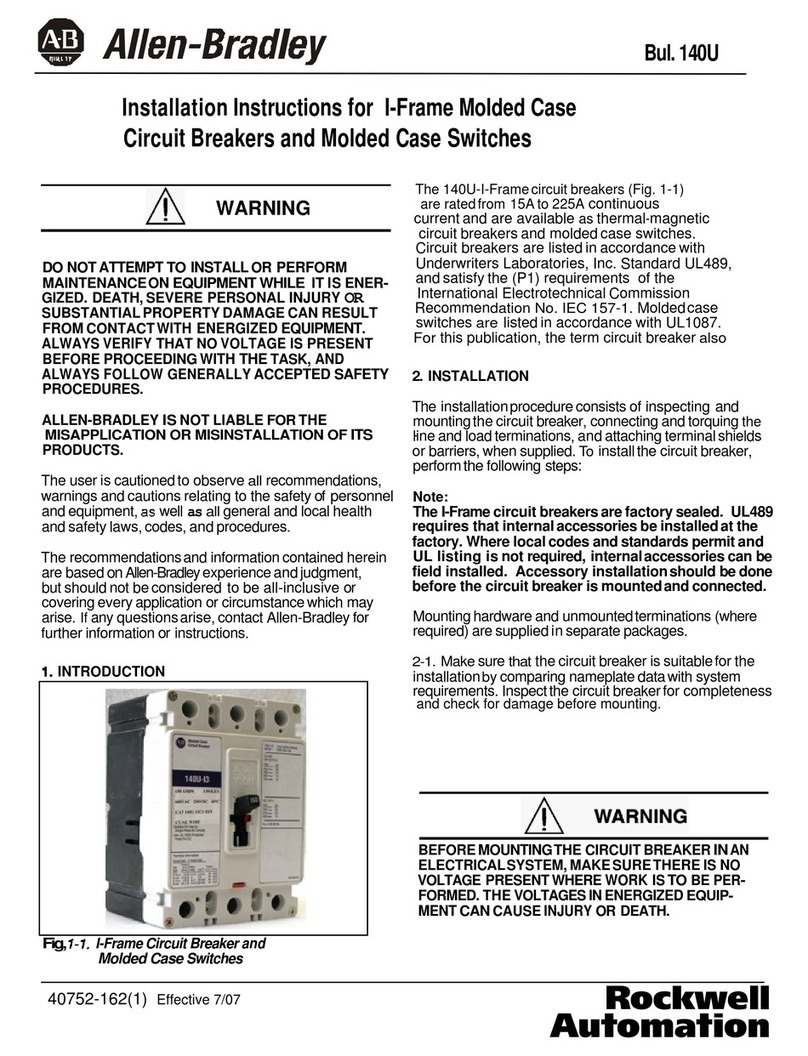

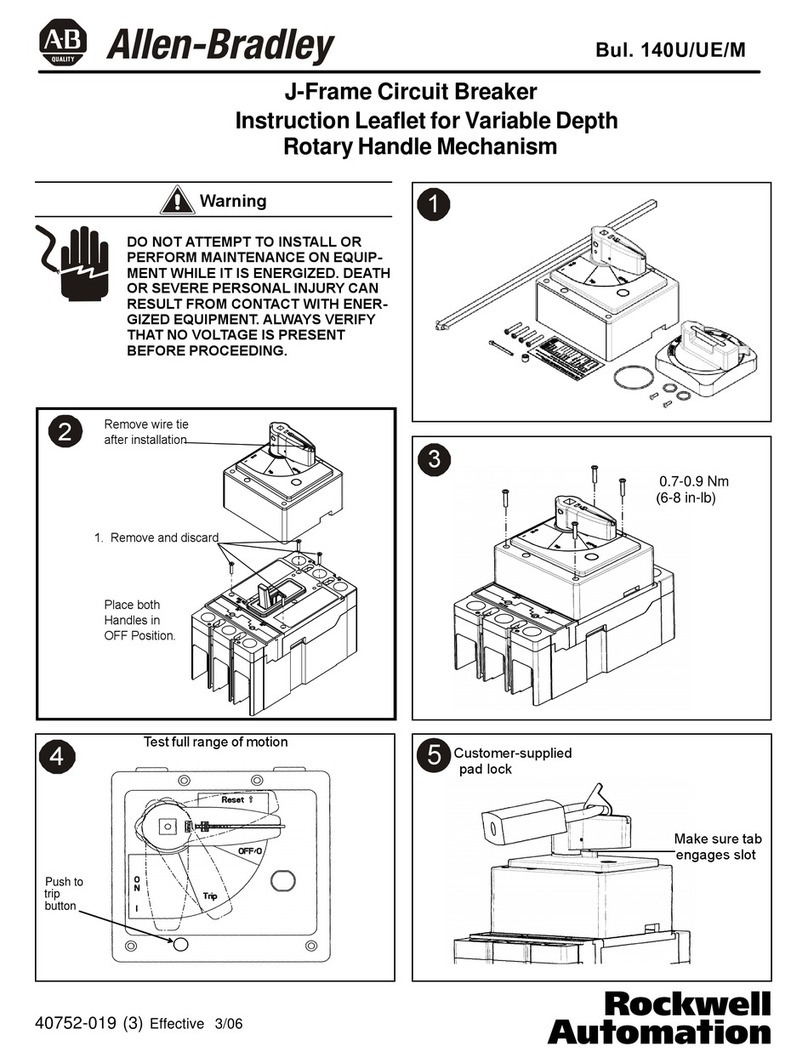

To mount the circuit breaker, perform the following steps:

1200A Front Connect Circuit

Breakers

a. For individual surface mounting, drill mounting panel

using the drilling plan shown in Figure 2-5. For dead front

cover applications, cut out cover to correct escutcheon

dimensions, see Figure 2-6.

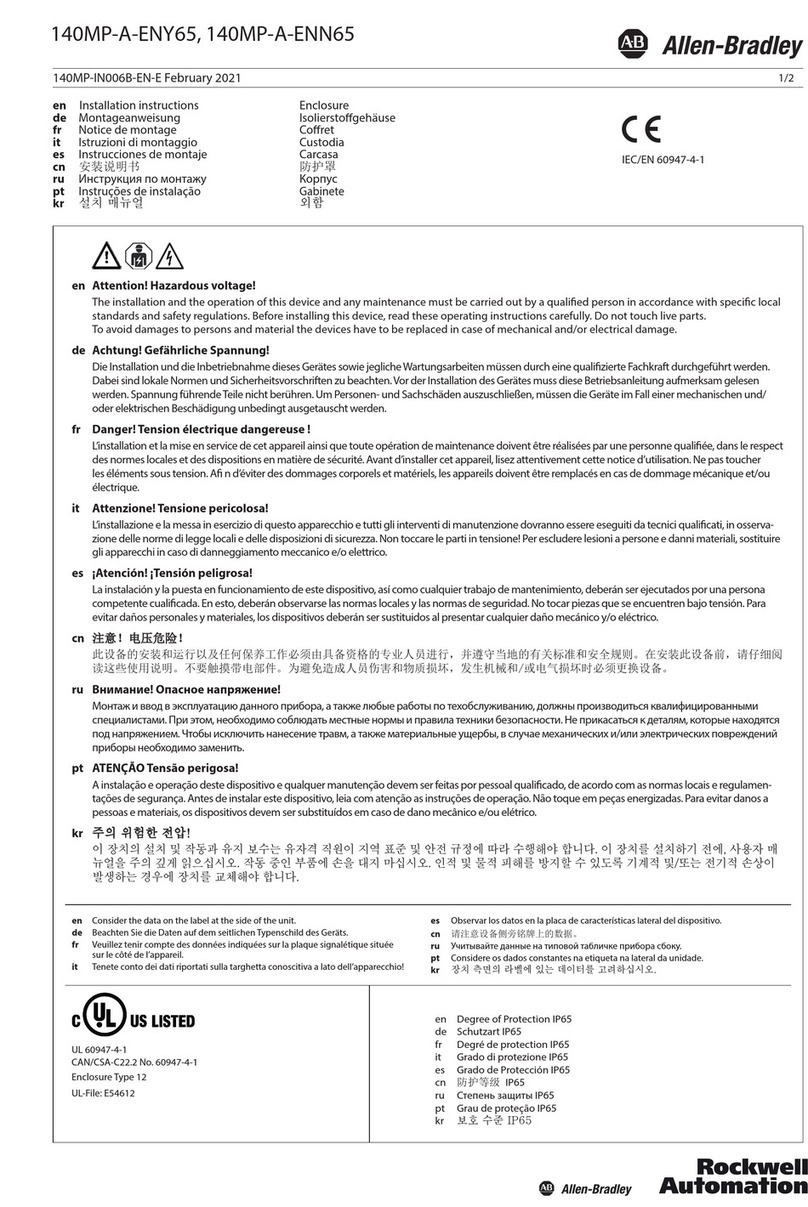

internal accessories, make sure the accessory wiring can

be reached when the circuit breaker is mounted.

Note: Labels with accessory connection schematic

diagrams are provided on the side of the circuit break-

er. A note should be made of the diagrams if the labels

cannot be seen when the circuit breaker is mounted.

c. Position the circuit breaker on the mounting surface.

d. Secure the circuit breaker with the supplied hardware

CAUTION

OVERHEATING CAN CAUSE NUISANCE TRIPPING

AND DAMAGE TO THE CIRCUIT BREAKER. WHEN

ALUMINUM CONDUCTORS ARE USED, THE APPLICA-

TION OF A SUITABLE JOINT COMPOUND IS RECOM-

MENDED TO REDUCE THE POSSIBILITY OF TERMI-

NAL OVERHEATING.

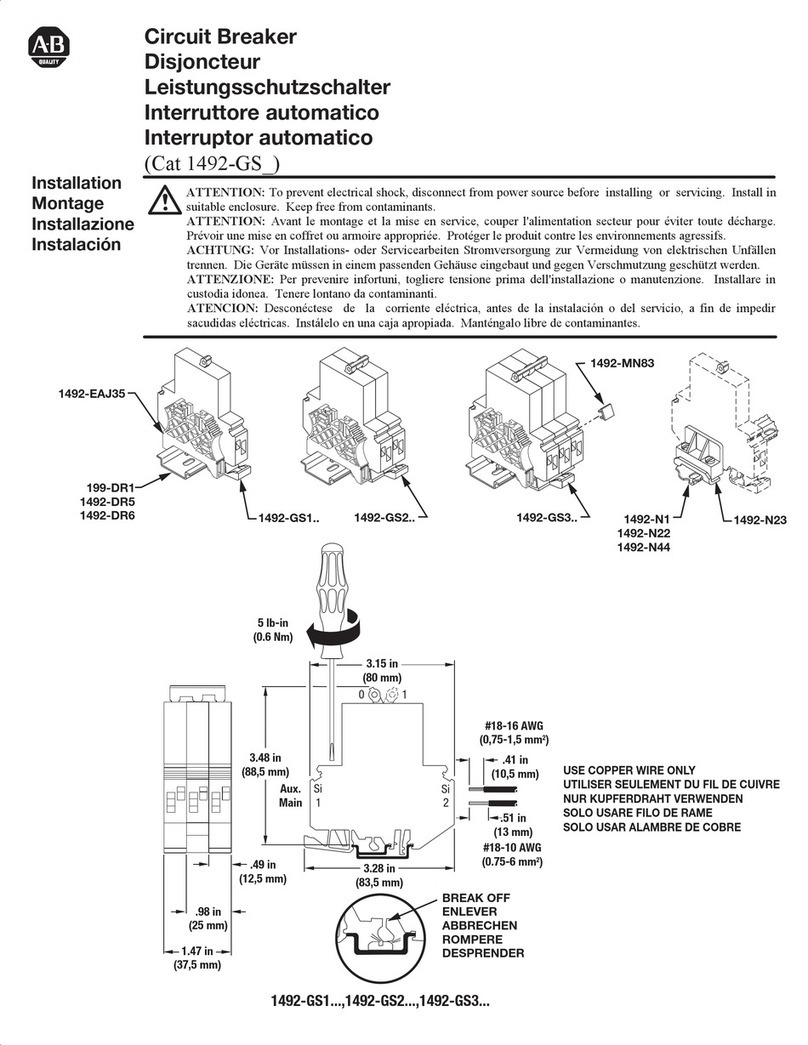

Connect line and load conductors and accessory leads. If

the circuit breaker includes ground fault protection, connect

the neutral current sensor and ground fault alarm unit as

.

HAZARDOUS VOLTAGE CONDITIONS CAN CAUSE

DEATH OR SEVERE PERSONAL INJURY. MAINTAIN

ORIGINAL ELECTRICAL CLEARANCE AND CREEPAGE

SPACINGS AT TERMINATIONS .

After the circuit breaker is installed and all connections are

made, check all mounting hardware and terminal connec-

tion hardware for torque loading. Torque values for line/

load terminal lugs are given on table in Figure 2-1. Torque

mounting screws to 30-35 lb-ft. (41-47 Nm).

Re-install load end and line end covers and secure with

pan head screws provided. Torque large screws to 35-45

lb.-in. (4.0-5.0 Nm) and small screws to 24-30 lb-in. (2.7-3.4

Nm). When using the terminals TA700NB1 or T700NB1,

or when prospective fault currents of cabled installations

exceed 65kA, (such as NDC applications), the conductors

are to be braced in accordance with Figure 2-9.

CAUTION

CAUTION

UNSUPPORTED CABLES CAN CAUSE MINOR PER-

SONAL INJURY OR EQUIPMENT DAMAGE UNDER

SHORT CIRCUIT CONDITIONS.

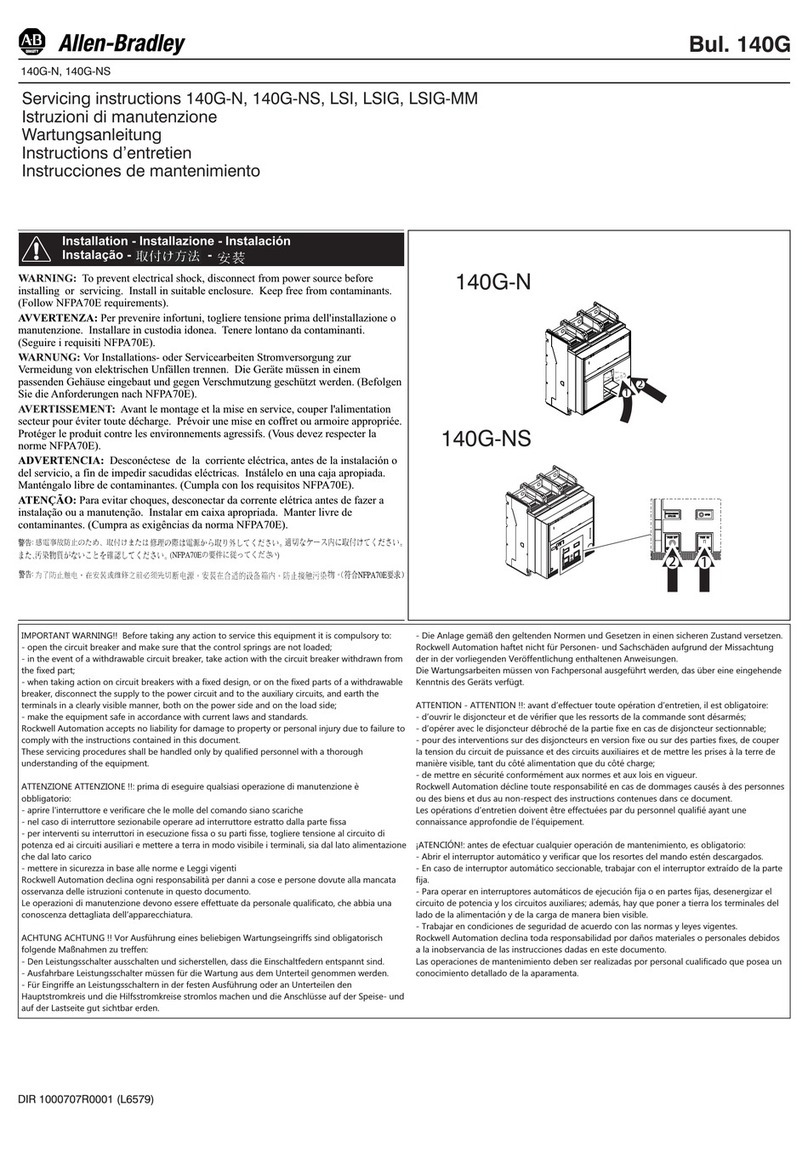

Wrap conductor cables with 3/8” nylon or equivalent

rope as shown in Figure 2-9, having a minimum tensile

strength of 2000 lbs., at 6” from terminals and every ad-

ditional 6” with 5 wraps or every additional 1” with 1 wrap.

2.6. Adjusting Trip Settings

The N-frame circuit breakers have the trip unit built in as

an integral part of the breaker. The trip unit is not field

replaceable. The various trip unit settings are described

in section 4. They should be adjusted as required

at this point.

2.4 Mounting

2.5 Connecting Line and Load Conductors