PureLine M Operation and Maintenance Manual

Page 2 of 54

5.4 CONTROL CABINET CONNECTIONS......................................................................................19

5.5 INSTALLATION AND PREPARING FOR OPERATION............................................................21

5.5.1 General ...............................................................................................................................21

5.5.2 Mechanical installation........................................................................................................21

5.5.3 Electrical installation ...........................................................................................................21

5.5.4 Preparing for operation.......................................................................................................22

5.6 OPERATION...............................................................................................................................23

5.6.1 Switching on and off............................................................................................................23

5.6.2 Automatic cleaning system.................................................................................................23

5.7 REMOTE CONTROL EVENT SEQUENCES.............................................................................24

5.7.1 Single valve mode...............................................................................................................24

5.7.2 Multi-valve mode.................................................................................................................24

5.8 WARNINGS AND TRIPS............................................................................................................26

5.8.1 Alarms screen.....................................................................................................................26

5.8.2 Resetting the system ..........................................................................................................26

5.8.3 Alarm log.............................................................................................................................26

5.9 SETTINGS..................................................................................................................................27

5.10 TROUBLESHOOTING ...............................................................................................................31

5.10.1 Alarms.................................................................................................................................31

5.10.2 Malfunctions of the temperature sensor .............................................................................32

5.10.3 Other troubleshooting .........................................................................................................33

5.11 REPORTING DATA....................................................................................................................34

5.11.1 Database records................................................................................................................34

5.11.2 Backing-up data..................................................................................................................34

5.11.3 Replacing the memory card................................................................................................34

5.11.4 Generating reports..............................................................................................................35

5.11.5 Exporting reports.................................................................................................................35

6. MAINTENANCE OF THE REACTOR AND THE CONTROL CABINETS..............36

6.1 CLEANING THE QUARTZ SLEEVES........................................................................................36

6.1.1 General ...............................................................................................................................36

6.1.2 Chemical cleaning method..................................................................................................36

6.2 CLEANING THE UV SENSOR AND QUARTZ WINDOW .........................................................36

6.2.1 Cleaning procedure.............................................................................................................37

6.3 MAINTENANCE OF THE AUTOMATIC CLEANING MECHANISM..........................................39

6.3.1 Introduction and safety aspects..........................................................................................39

6.3.2 Wiper replacement procedure.............................................................................................39

6.4 VENTILATION OF THE CONTROL CABINET ..........................................................................41

6.5 EARTH LEAKAGE CIRCUIT BREAKER CHECK......................................................................41

6.6 CLEAN-IN-PLACE......................................................................................................................41

7. REPLACING LAMPS AND QUARTZ SLEEVES ...................................................42

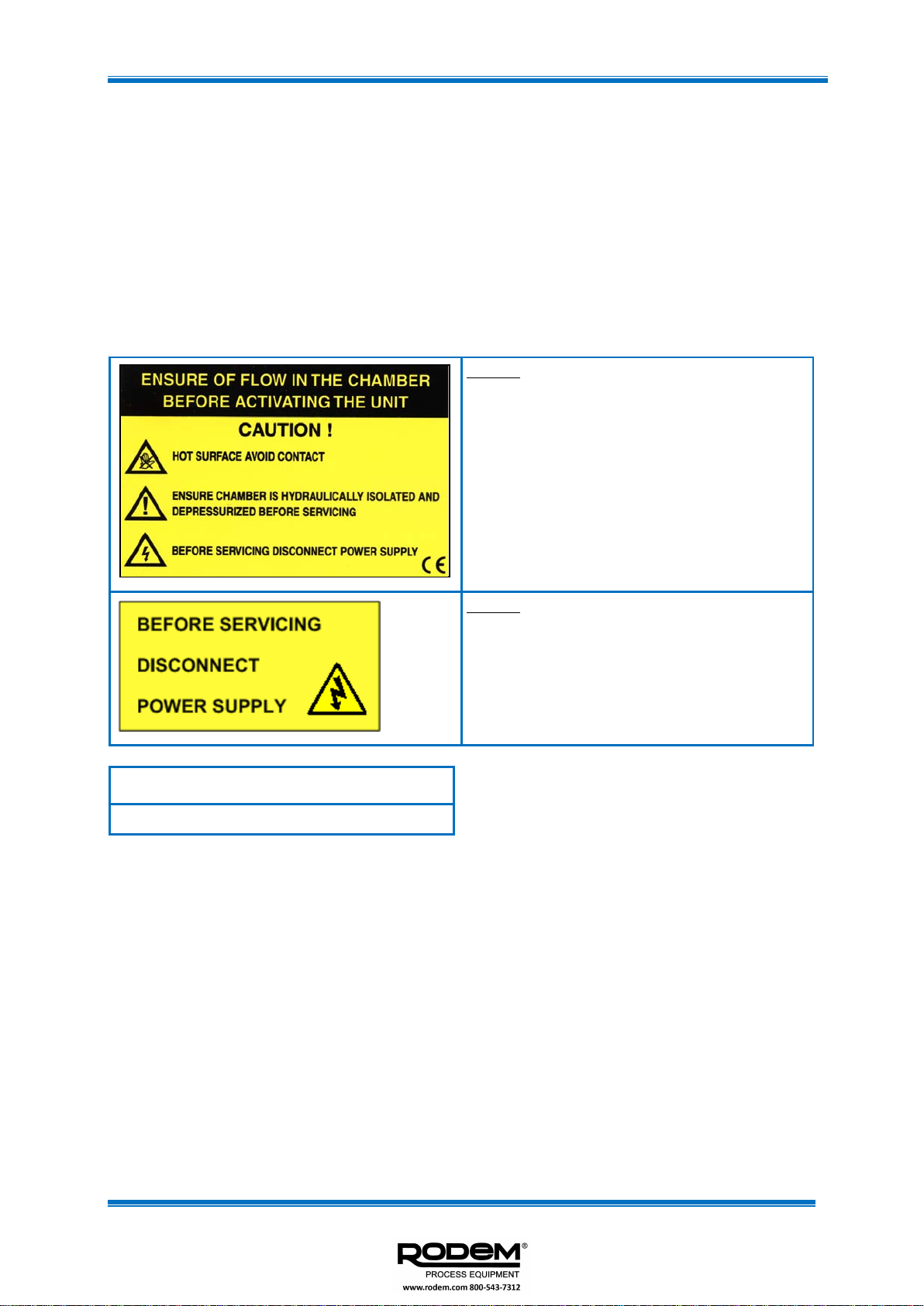

7.1 SAFETY PRECAUTIONS...........................................................................................................42

7.2 MAIN REPLACEMENT PROCEDURE ......................................................................................43

7.2.1 Resetting the service history...............................................................................................48

7.3 REMOVING QUARTZ SLEEVES WITH THE JUPITO ..............................................................49

8. DISPOSAL..............................................................................................................51

8.1 GENERAL...................................................................................................................................51

8.2 RETURNING OLD LAMPS.........................................................................................................51