6) Remove the vibration sensor from its protective

packaging. Remove the liner from the adhesive

backing. Avoid touching the tape. Align the

sensor as shown in figures 1 and 2. Apply the

vibration sensor to the prepared area of the

feeder. Press the sensor very firmly onto the

feeder surface for at least 10 seconds.

7) Allow the vibration sensor at least 20 minutes to

cure before operation. Note it takes 72 hours for

the adhesive to fully cure at 70°F.

Alternatively, #8 or M4 screws can be used to mount

the sensor to the feeder. The hole centers are 1.375”

(3.49cm) apart.

D. ROUTE THE SENSOR CABLE to protect it from

strain due to vibration. The cable that attaches to the

sensor will not break from normal vibration; however,

some care should be used when routing the sensor

cable from the sensor to the control. The cable

should hang straight down from the sensor without

touching the feeder bowl or anything else. Then, the

sensor cable should curve towards the power control

with a bend radius larger than 3 inches (8cm).

Use a cable tie and an adhesive-backed mount to

attach the sensor cable to the side of the drive base.

See Figure 2. Clean the mounting area before

applying the adhesive-backed mount.

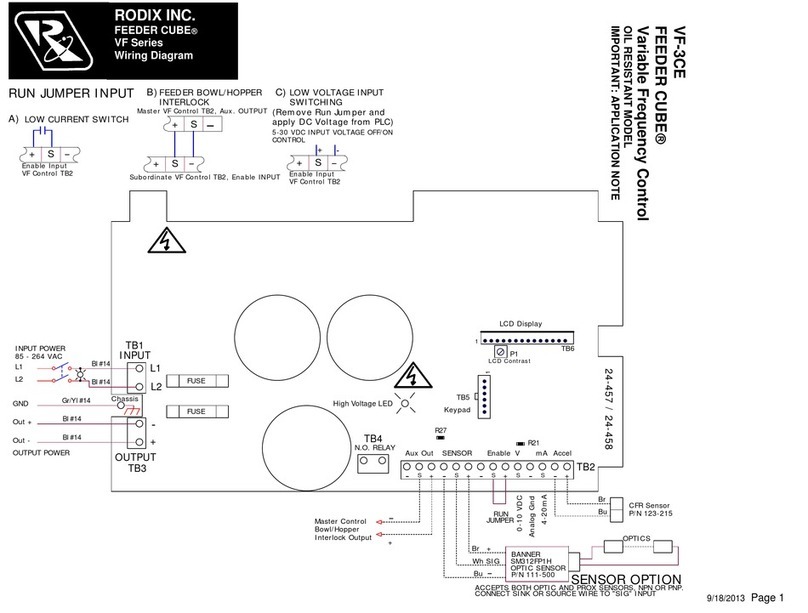

E. CONNECT THE SENSOR to the control. The

sensor’s brown wire connects to +12VDC at TB2-9.

The blue wire connects to the signal input at TB2-12.

14. SETTING CFR GAIN SELECTION

The CFR response rate can be increased with “High

Gain”. If the response is too quick, oscillating or

unstable, use “Low Gain”. See the S1 switch

selections for the “High” and “Low” CFR Gains.

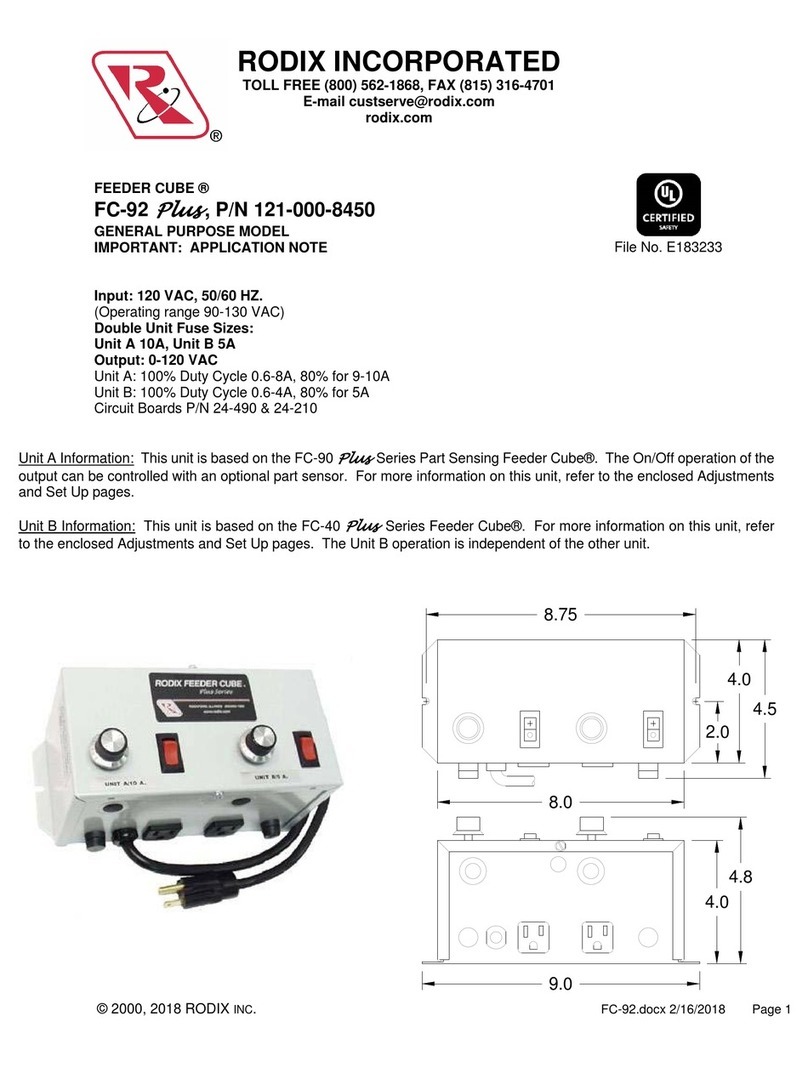

15. OUTPUT CONNECTIONS

The 120V models in general purpose enclosures

provide a standard North American receptacle

(NEMA 5-15R) for connection to the feeder. 240V

models have a pigtail output cord. Power cords are

optional on Oil Resistant models.

16. SUPPLEMENTARY FEATURES

Special supplementary software features can be

enabled on the 24-490/24-491 circuit boards.

Included features: Constant On, High/Low Track level

control, 60 pulse polarity reversal, low pulse rate,

linear pot taper, Constant Feed Rate response time,

bowl out of parts, and two speed pots. See the S1

Switch Programming Chart. For more feature

information download (or request from RODIX) the

FC-90

Plus Series

Advanced Application Note.

17. STATUS LEDs

When the Sensor input is active, either the PNP or

NPN LED will be ON. When the RUN input circuit is

complete, the RUN LED will be ON. The AUX LED is

ON whenever the Aux output is turned ON.

TROUBLESHOOTING

For the control to run: The RUN LED must be lit (see

Run Jumper Input chart on wiring diagram). The Main

Control Dial or 4-20mA signal must be present. Turn

the ON and OFF delay pots down CCW. The DIP

switch S1 must be set to match the sensor’s output

type, PNP or NPN. The PNP or NPN LED must light

up and turn off when making and breaking the 3- wire

DC parts sensor. If no parts sensor is connected, set

theS1INV/NORMswitchto“Invert”. Ifthefeederonly

hums, toggle the 60/120 dip switch.

For more troubleshooting helps, download the FC-90

Plus

Troubleshooting Guide at rodix.com

WARNING:

Fuses should be replaced with Bussman ABC or

Littelfuse 3AB "Fast Acting" type or equivalent of

manufacturer's original value.

Mounting this control on a vibrating surface will

void the warranty.

WARRANTY

Rodix Control Products are Warranted to be free from

defects in material and workmanship under normal use

for a period of two years from date of shipment. For the

full description of the warranty, terms, and software license,

please contact the factory.

For assistance installing or operating your Rodix Feeder

Cube® please call the factory or visit our web site.

Technical help is available to answer your questions and

email any needed information. To return a control for IN or

OUT of warranty service, please ship it prepaid to:

Rodix Inc., ATTN: Repair Department

If under warranty, Rodix will repair or replace your control

at no charge; If out of warranty, we will repair it and you will

be billed for the repair charges (Time and Material) plus the

return freight. Quotes for repairs are available upon

request. A brief note describing the symptoms helps our

technicians address the issue.

Feeder Cube® is a registered TM of Rodix Inc.

Banneris a registered Trademark of Banner Engineering Corp,

9714 10th Ave, Minneapolis, MN 55441

RODIX, INC.

2316 23rd Ave., Rockford, IL 61104

Toll Free (800) 562-1868, FAX (815) 316-4701

rodix.com

FC-90 Plus Set Up J.docx 2/21/2018 Page 5

S1 Pro

rammin

Chart

Pro

ram Description S1 Sw. Positions

Switch 6 7 8 9 10

Standard Pro

ram 0 0 0 0 0

Constant ON 0 0 0 0 1

Hi

h/Low Track 0 0 0 1 0

Linear Pot Taper 0 0 0 1 1

0-20m

00100

2-Speed Operation 0 0 1 0 1

Bowl Out Parts, Stop 0 0 1 1 0

BOP stop/ with alarm 0 0 1 1 1

BOP alarm w/o stop 0 1 0 0 0

30/15 hertz operation 0 1 0 0 1

ux Invert 0 1 0 1 0

ir Jet Timers 0 1 0 1 1

40 Pulse operation 0 1 1 0 0

Low Amplitude at “1” 0 1 1 0 1

Low CFR Gain 0 1 1 1 0

Hi

h CFR Gain 0 1 1 1 1

Waveform Reversal 1 0 0 0 0

Constant ON, WR 1 0 0 0 1

Hi

h/Low Track, WR 1 0 0 1 0

Linear Pot Taper, WR 1 0 0 1 1

0-20mA, WR 1 0 1 0 0

Option Pro

. 1 0 1 0 1

Option Pro

. 1 0 1 1 0

Option Pro

. 1 0 1 1 1

+

TB2

12 9

-

Brown

CFR SENSOR

123-170

11

Blue

10