ROJEK a.s. 4 RFS 410, 510

Introduction

This manual was conceived at the manufacturer and is an indivisible part of the delivery

enclosed with the machine. It contains basic information for qualified operating staff and dis-

cribes the surroundings and using ways of the machine for those it is intended. It contains

also all necessary information for a correct and safe operating.

The machine is equipped with various safety equipment protecting the operator and ma-

chine as well at usual technological using. These regulations, however, cannot sheet all

other safety aspects. That is why the operator must peruse and make sense of this manual

before starting of using the machine. Installation and operation mistakes will be foreclosed

herewith.

Do not try to start the machine before having read all instructions manual delivered

with the machine and understood every function and technique.

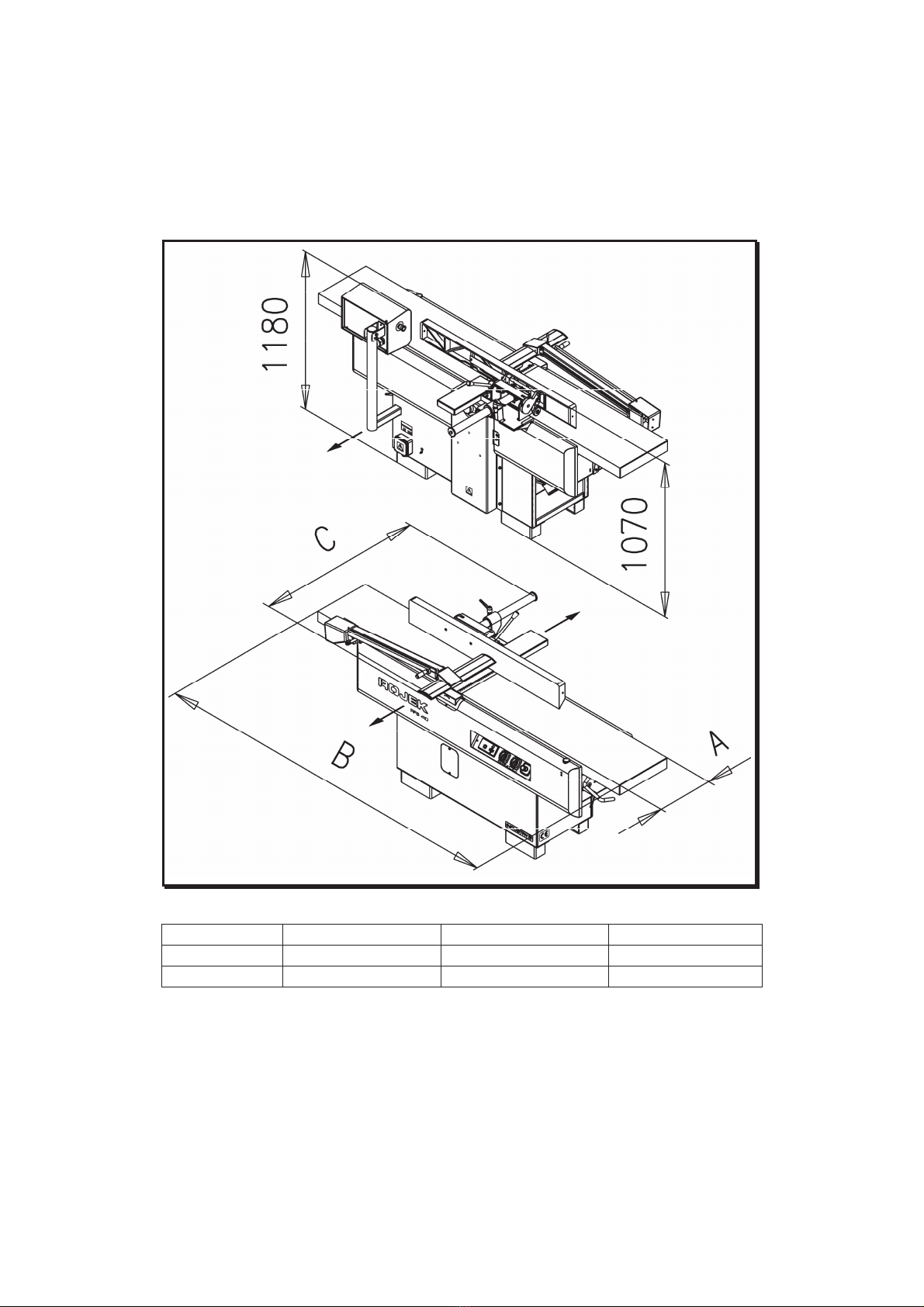

Some information or drawings need not be intended especially for by yours bought type,

for this manual contains all information of other this type variants we produce.By comparing

of competent manual part with your machine - you will learn whether they correspond.

The producer reserves himself the right for particular variants in frames of a fluent tech-

nical development of the machine.

To stress the importance of some basic passages better, they are printed in heavy letters

and marked by some preceding symbols - Appeal recommending to follow entirely following

regulation :

Breach of these regulations may cause the death or a grave

health exposure of operating personnel.

Warning against improper techniques or using of machine

that may cause an exposure of human health, machine

functioning and environment or cause economic losses.

The caution is an appeal to a due care for practising of fol-

lowing operations. Non-performing this caution may cause a

human injury or damage of the machine.

The caution is an appeal to a due care for practicing following operations. Non-performing

this caution may cause a human injury or damage of the machine.

Notice

The text and pictures of this manual is a know how of the ROJEK Co. No part of it can

be copied and third persons are not allowed to learn it or its part without the company´s

approval.