7

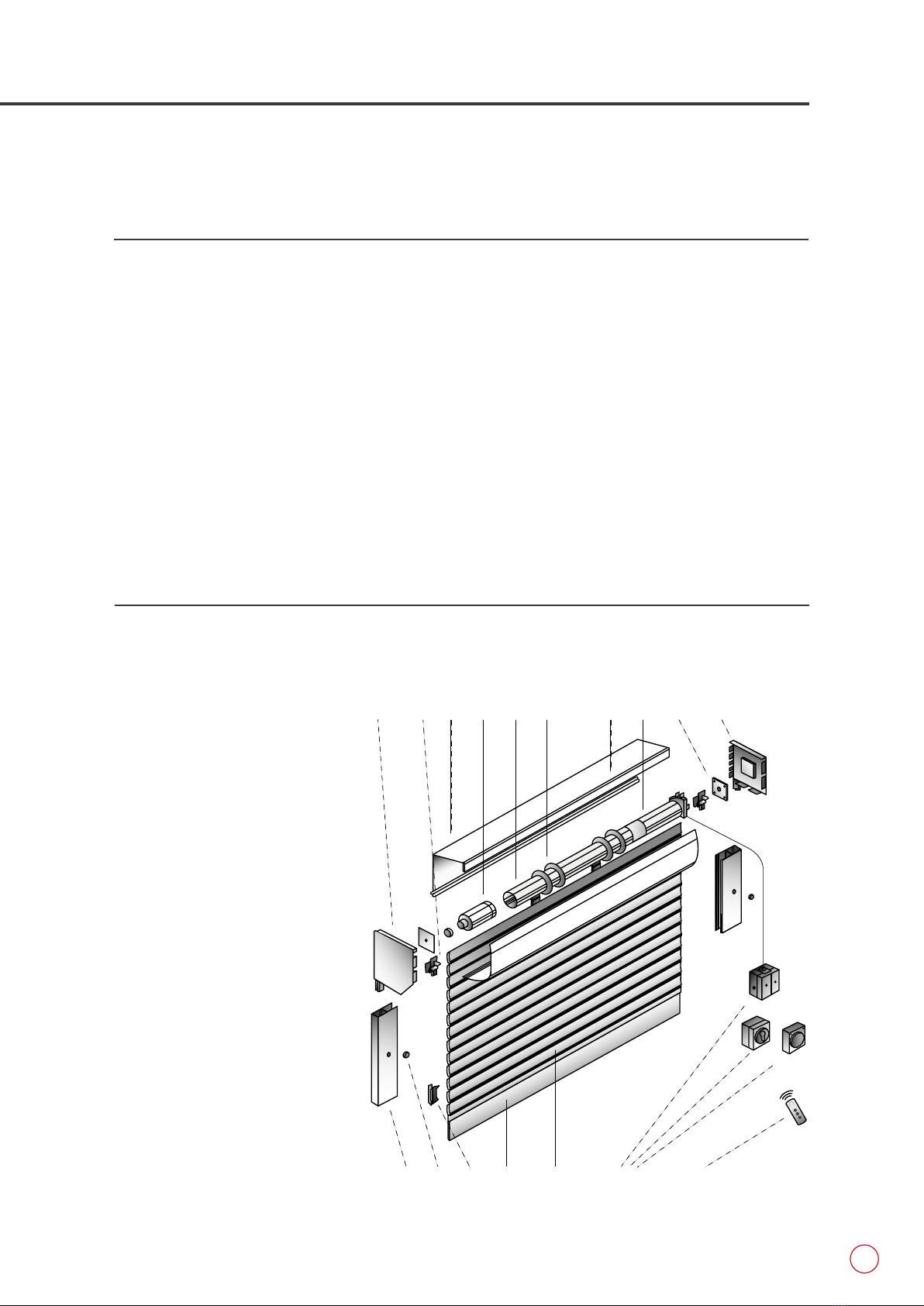

3. INSTALLING HEADER ASSEMBLY

1 Place your hop ups / step ladders

and one guide runner each side of

the opening.

2 With one person each end, lift the

header assembly by the header

plate up and into place, then guide

the locating stem at each end into

the hollow section of guide runners

(this can be made easier by slightly

angling the header if there is not

enough room to simply drop the

locating stem in) (fig.3.1).

3 Lift the whole unit flush into place

and check that the top box and

guide runners are plumb level and

square (fig.3.2 & fig.3.3).

4 Drill a 7mm fixing through the

top hole in the guide runners and

secure into place (fig.3.4).

5 Check the case and guide runners

are still level and square, then

proceed to drill a 7mm fixing

through the remaining holes,

remembering to check the guide

runners are square and plumb after

each fixing.

6 Check to make sure all fixings have

not caused the front fascia to be

pulled in, as this will rub against

the slats causing damage and

scratching to the face.

7 Seal down the sides and along

the top case (silicon sealant is

recommended).

fig.3.1

fig.3.3

fig.3.2

fig.3.4

8 (For Internal Manual Override system)

Remove winding stem from your winding

handle where it has been taped securely.

9 (For External Manual Override system)

remove metal shaft via the plastic circlet

(p.34, fig.15.1, number 4 ).

10 Remove screw from end of stem and keep

safe for later.

11 Cut cable ties and release curtain, and place

available curtain into guide rails through the

mouth of the guides.

12 Insert winding stem through pre-drilled

hole in header plate. Turn to release

more curtain into guides, roughly 4

slats in total, remove winding stem and

keep safe for later.