7

Rollerdor RD77 Installation Guide, Edition 2022/01

3. PREPARING GUIDE RUNNERS

FOR INSTALLATION

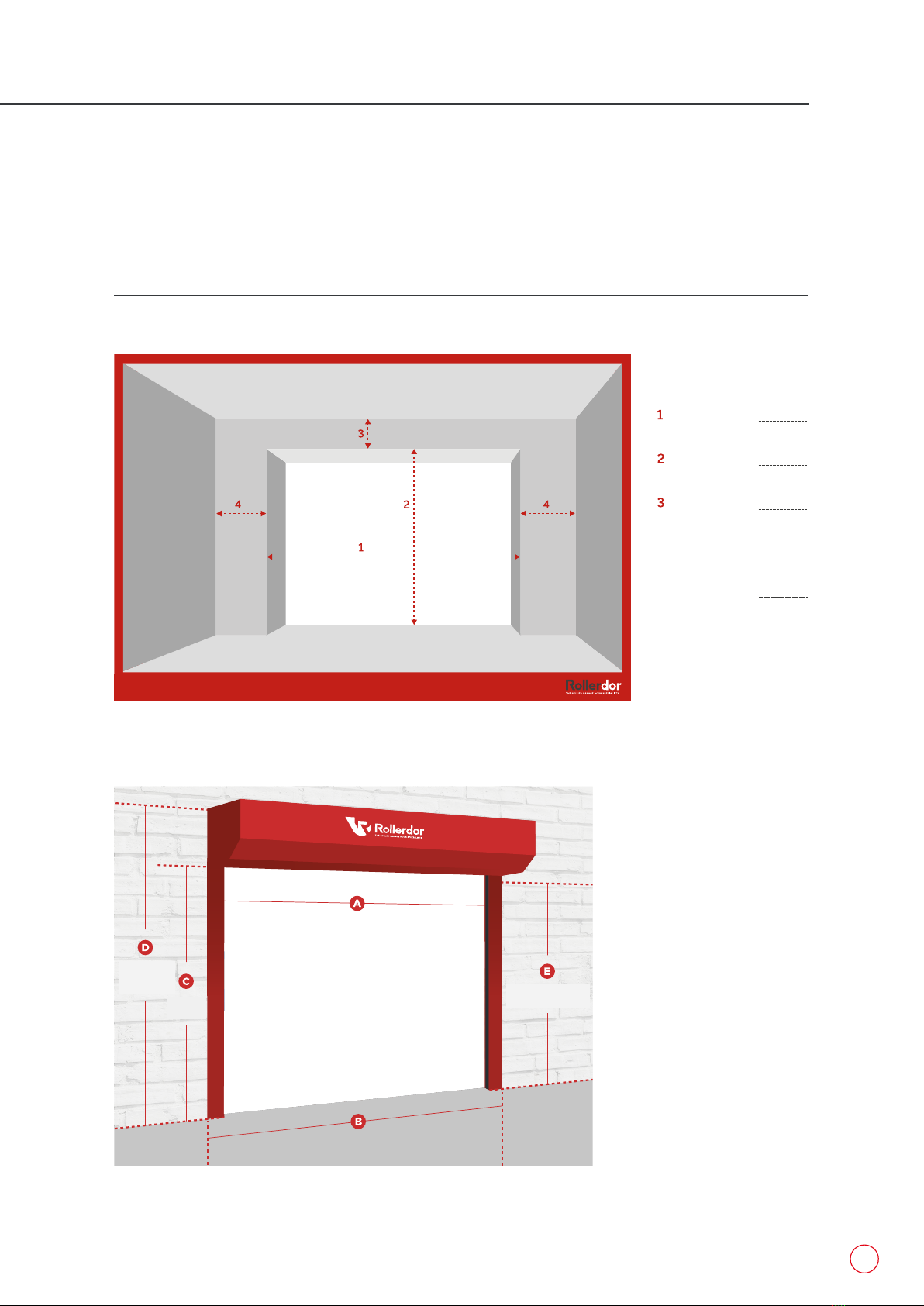

1 We use 2 types of guide runners

whichever is supplied with your kit will

be marked with the letter ‘F’ to indicate

the front, as seen in (fig.3.1 type 1) and

(fig.3.1 type 2). This marked face will

fit against the wall for a standard back

fixing or face out of the opening for a

between fixing (fig.3.5).

2 Your guide runners are supplied

oversize and need to be CUT down

to size, check the lintel is level then

measure from floor to lintel both sides

before referring to (fig3.6) and making

the cuts as necessary (for best results,

install the guide runners so that the cut

end is against the floor).

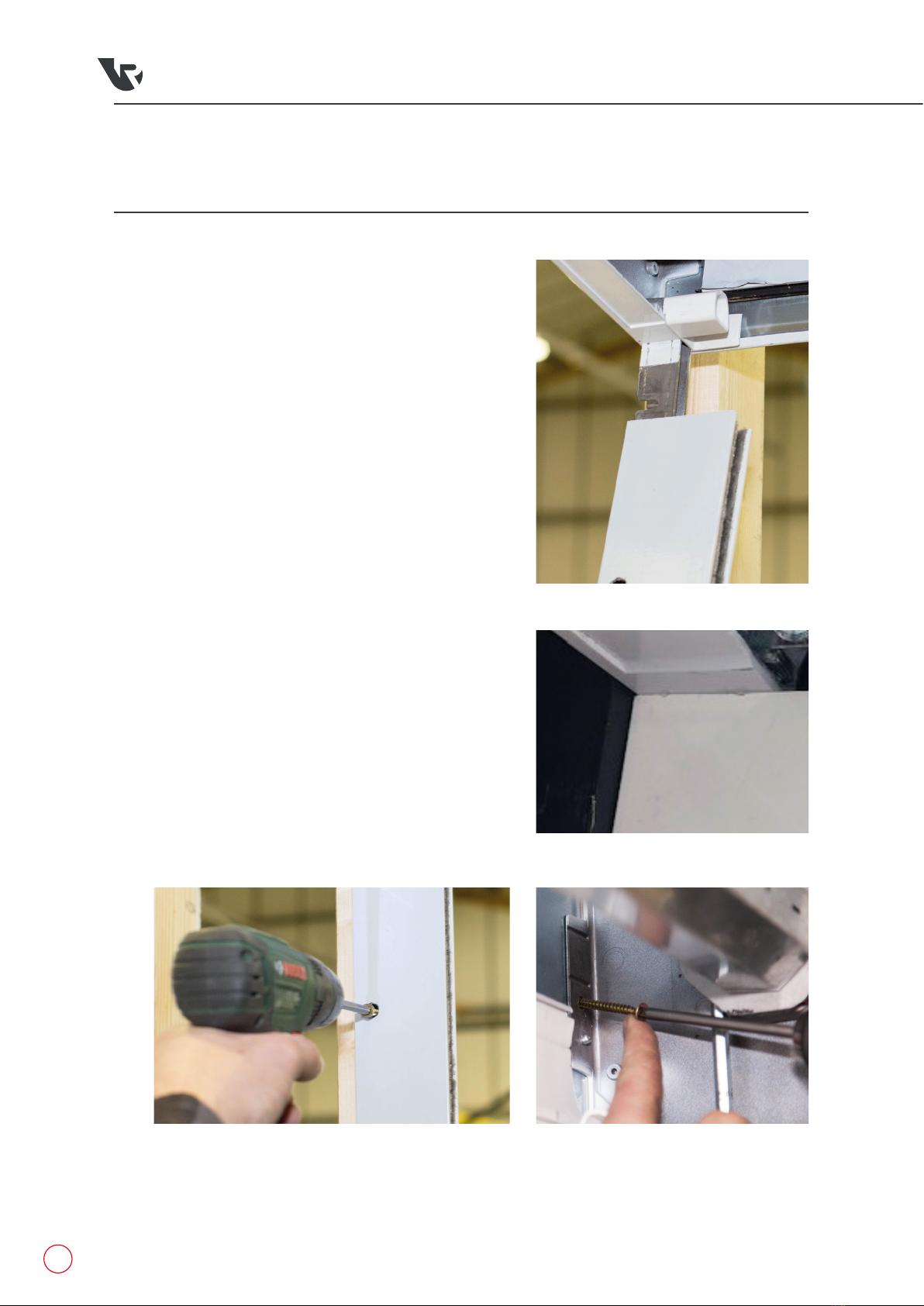

3 Offer both cut guide runners up against

the walls they will be fixed to and mark

the fixing points, either on the flat face

for a behind fixing (fig.3.3) or for a

between fixing in the opening (fig.3.4).

For best results these should be as

follows;

A Top fixing between 50mm to

100mm down from the top of the

guide rail.

B Bottom fixing 50mm to 100mm

up from the floor.

C Marking as many fixings as

necessary but must be at least

two extra fixings. Spread these

evenly between the two already

marked points on the guide

runners so that you have a secure

fix.

D Drill a 7mm hole all the way

through each of the marks

and then drill a 10mm hole to

countersink through the first layer

only so you can get the screw

head through.

fig.3.2

fig.3.4

fig.3.3

(fig.3.1 type 1)

Front Face

(fig.3.1 type 2)

Front Face