R X 2 5 0 0 A S S E M B L Y I N S T R U C T I O N S & M A N U A L 32- 0 0 1 6 R E V . B

2

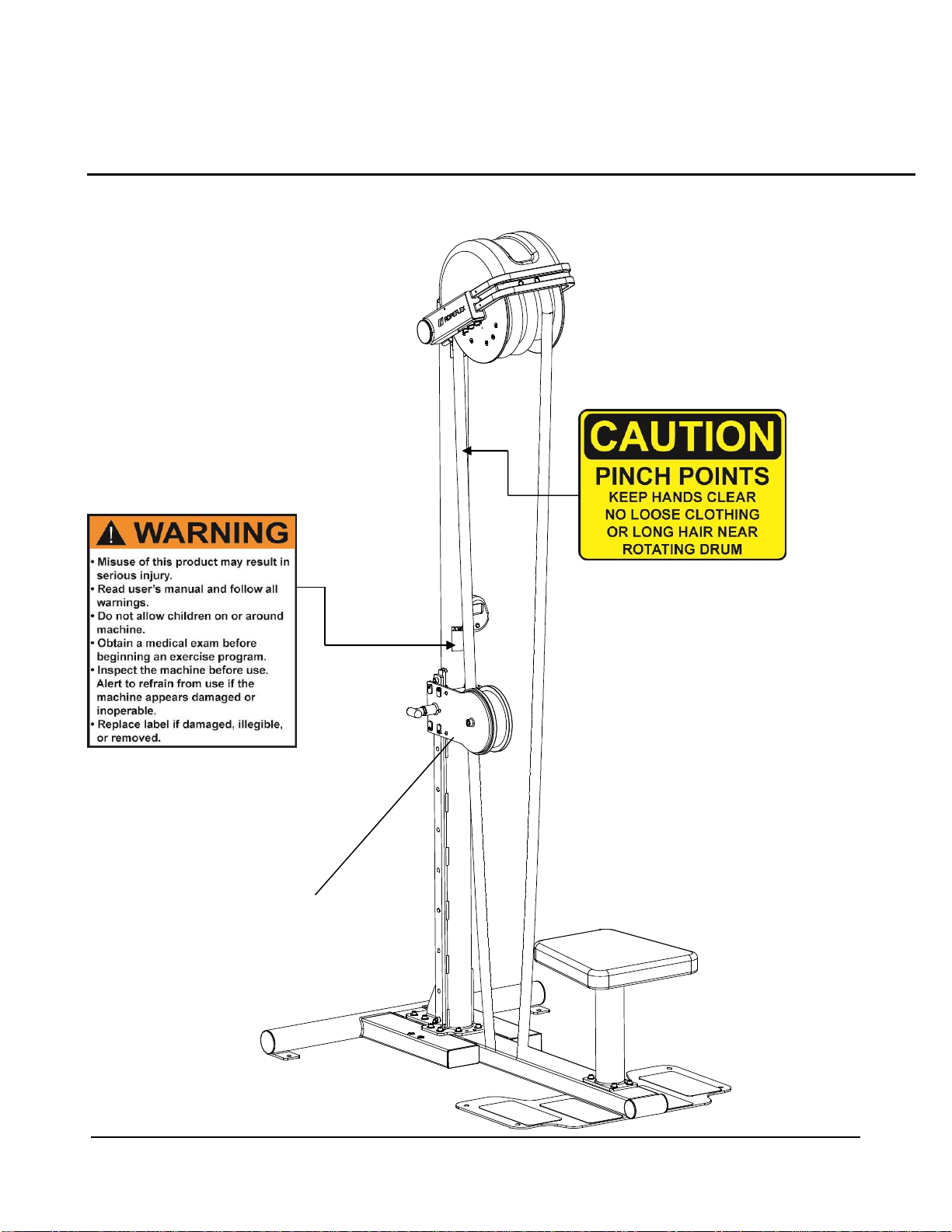

IMPORTANT PRECAUTIONS

WARNING: To reduce the risk of serious injury, read the following important precautions

before using this equipment.

1. Read all instructions in this manual and

assemble as described before using this

equipment.

2. It is the responsibility of the owner to ensure

that all users of this equipment are

adequately informed of all precautions.

3. Use this equipment only on a level surface.

Cover the floor beneath to protect the

surface.

4. Keep children under 12 and pets away from

the equipment at all times.

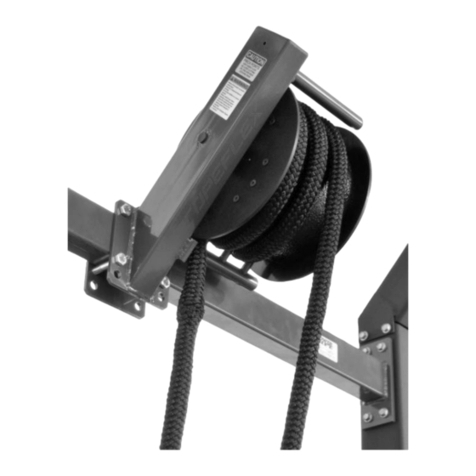

5. Make sure all parts are properly tightened

each time you use this machine. Replace

any worn parts immediately.

6. Make sure the adjustment knobs are fully

engaged / disengaged before using the

equipment.

7. Always wear athletic shoes for foot

protection while exercising.

8. This equipment is designed to support a

maximum user weight of 300 pounds.

9. Pull on one the rope only and never grab a

rope in a way that prevents the drum from

rotating. Never attempt to hang on the rope.

Pull rope with hands only.

10. If you feel pain or dizziness at any time

while exercising, stop immediately and

begin cooling down.

WARNING: Before beginning this or any exercise program, consult your physician. This is

especially important for persons over the age of 35 or persons with pre-

existing health problems. Read all instructions before using. HIPEQ assumes

no responsibility for personal injury or property damage sustained by or

through the use of this product.