1. Safety Precautions

31/3/2022 Written and illustrated by Ben Sprules

Rosemor International Ltd 2022 © 5

1.1 Preliminary Remarks

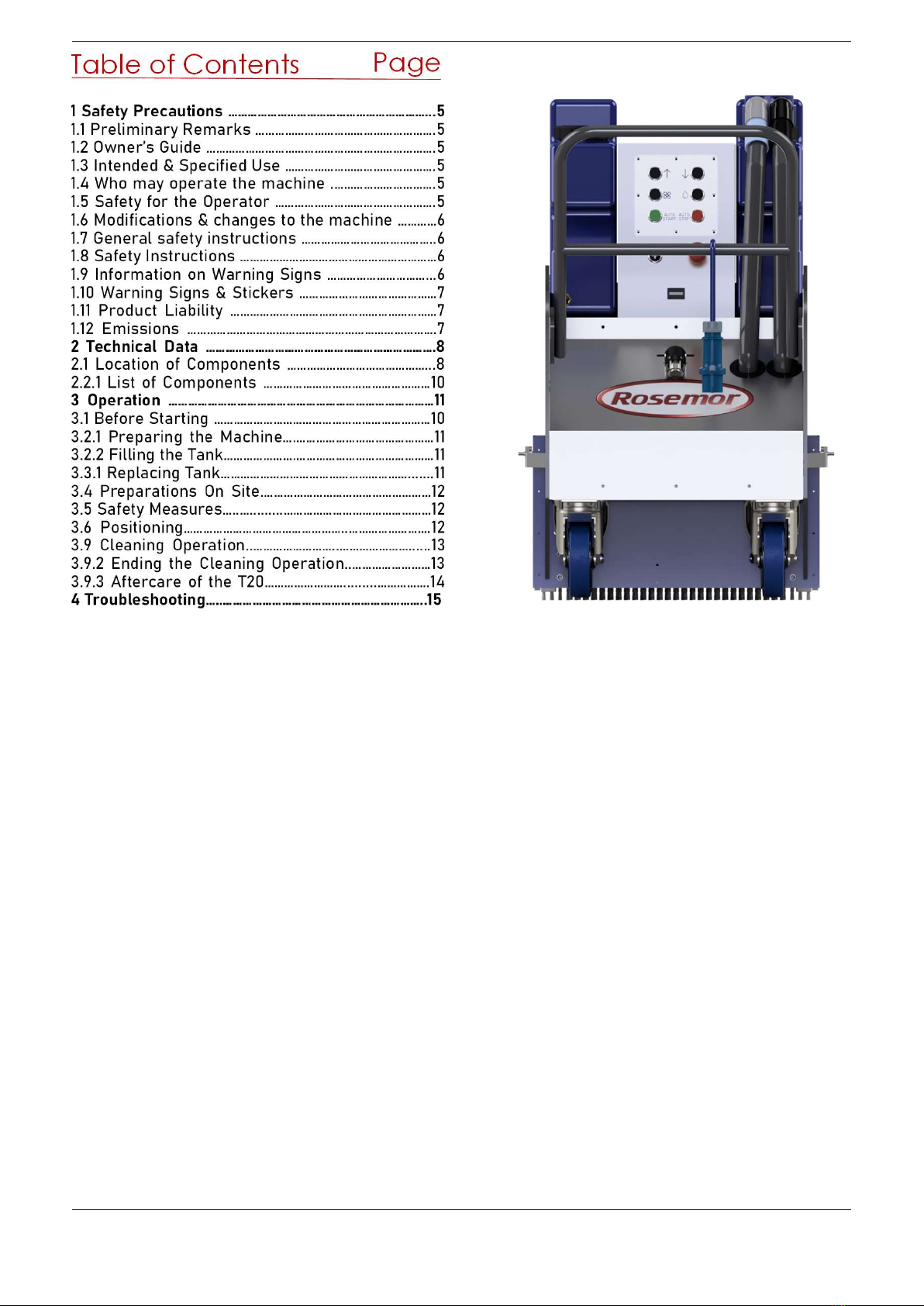

The automatic escalator/travelator deep

cleaning machine (T20i) was designed and

manufactured according to state-of-the-art

technology and in compliance with all relevant

regulations. This, however, does not guarantee

that some other unavoidable dangers for

persons and property can occur. All personnel

working with this machine must therefore read

and follow these operating instructions, and in

particular, be fully trained in all of the relevant

safe operating procedures provided by Rosemor

International Ltd or one of its authorised

specialists.

These operating instructions must remain at the

machine for use by the operator. Each operator

must receive thorough training on handling and

working with the machine.

1.2 Owner’s duties

In accordance with EU directive on the use of

operating equipment 89/655/EEC Art.6(1) and 7

and EU framework directive 89/391/EEC Art.1(1)

and Art. 6(1), the owner of the equipment is

obliged to instruct all persons, particularly with

regard to safety, who will be authorised to work

on assembly, operation, maintenance, repair or

dismantling of the machine.

The owner is also obliged in accordance with EU

directive on the use of operating equipment

89/655/EEC Art.4a to inspect the machine before

start-up, following repair work and following

faults or malfunction.

1.3 Intended and specified use

The automatic escalator/travelator deep

cleaning machine (T20i) is exclusively intended

for basic cleaning of indoor and outdoor

escalators and travelators. Any use beyond this

stipulation must be considered as contrary to

the manufacturer’s intentions. The manufacturer

will not be liable for any damage resulting from

such work; all risk in this case will be borne

exclusively by the operator. Correct use of the

machine also includes compliance with the

conditions of operation and maintenance

stipulated by the manufacturer.

• The automatic escalator deep cleaning machine

T20i are not intended, nor suitable for cleaning

hazardous dirt or substances.

• The machine is not fire-proof.

• The machine is also not licensed for use in

cleaning public streets and paths.

1.4 Who may operate the machine?

The machine may only be used by persons who

have been trained in its operation and who are

expressly authorised to carry out such work.

These persons should be at least 18 years old.

All relevant accident prevention regulations and

other generally recognised rules of safety,

engineering, industrial medicine and the

Highway Code must be strictly observed.

Assembly, equipment, maintenance and repair

work demand special knowledge and may only

be carried out by specially trained persons.

1.5 Safety for the operator

• The user must under no circumstances touch

the plug of the power supply with damp hands.

• When the machine is being disconnected from

the power network, only the plug itself may be

pulled - never the power cable.

• The machine may be repaired or opened only

by qualified personnel.

- Non-Slip safety footwear is essential when

using this machine.

- The operator should never be allowed to

become distracted or startled when

operating this machine. Do not try to engage

in conversation or attain the attention of the

operator when they are using this machine.

If work on the opened machine within

connected current is absolutely

necessary, such work may be carried out

only by a qualified electrician who is

familiar with all attendant dangers and

the relevant work stipulations (VDE0100).

When work is carried out on machine or

parts when live, only tools specially

intended for this purpose may be used.