CONTENTS

0CAUTION ................................................................................................................................................ 3

0.1 Preliminary Safety Information ............................................................................................................ 3

1INTENDED USE ..................................................................................................................................... 4

2OPERATOR TRAINING ....................................................................................................................... 4

2.1 General Preventive Measures ............................................................................................................... 4

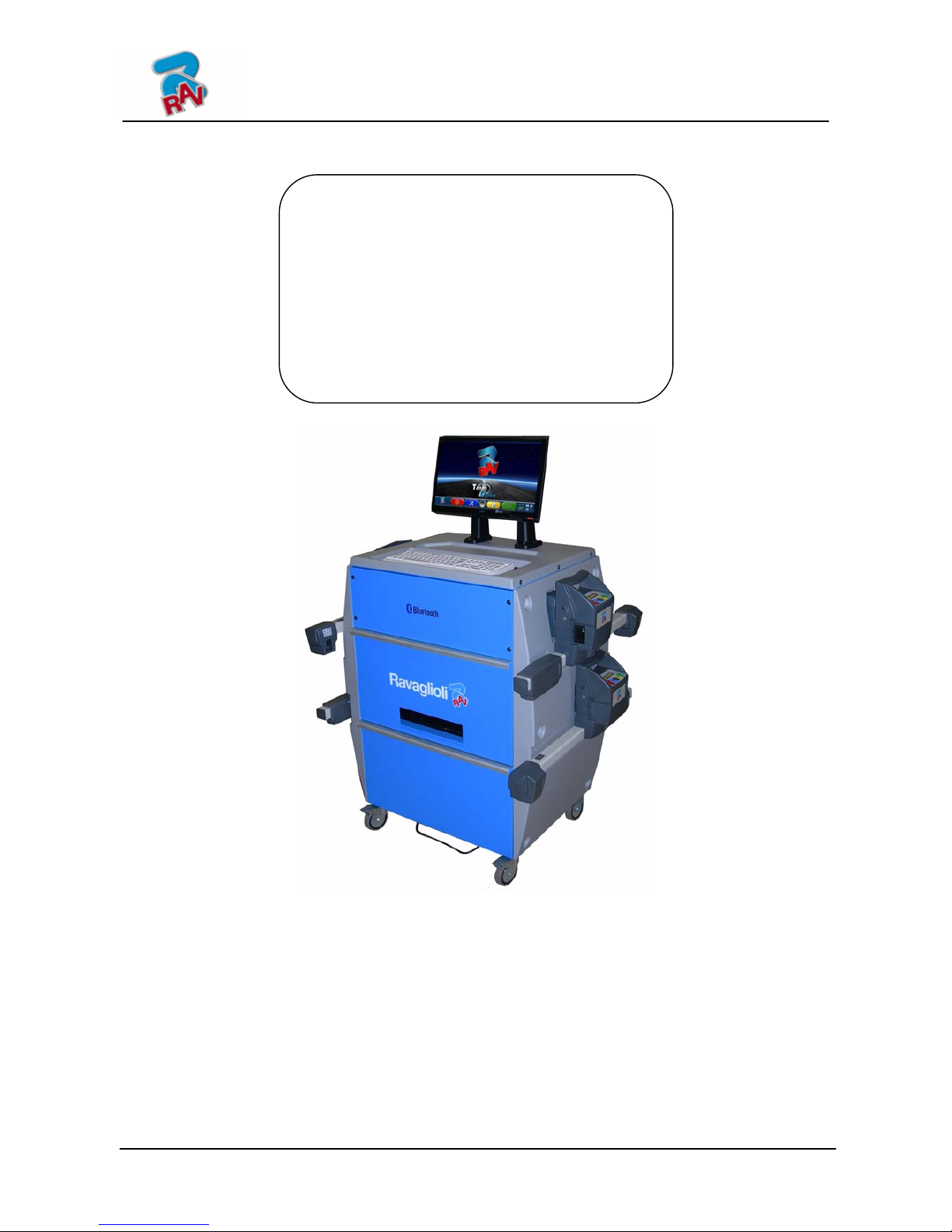

3MACHINE COMPOSITION ................................................................................................................. 5

3.1 Models RAVTD1780WS – RAVTD1760WS Composition ................................................................ 5

3.2 Safety Devices ...................................................................................................................................... 6

3.3 Measurement Range and Accuracy ...................................................................................................... 6

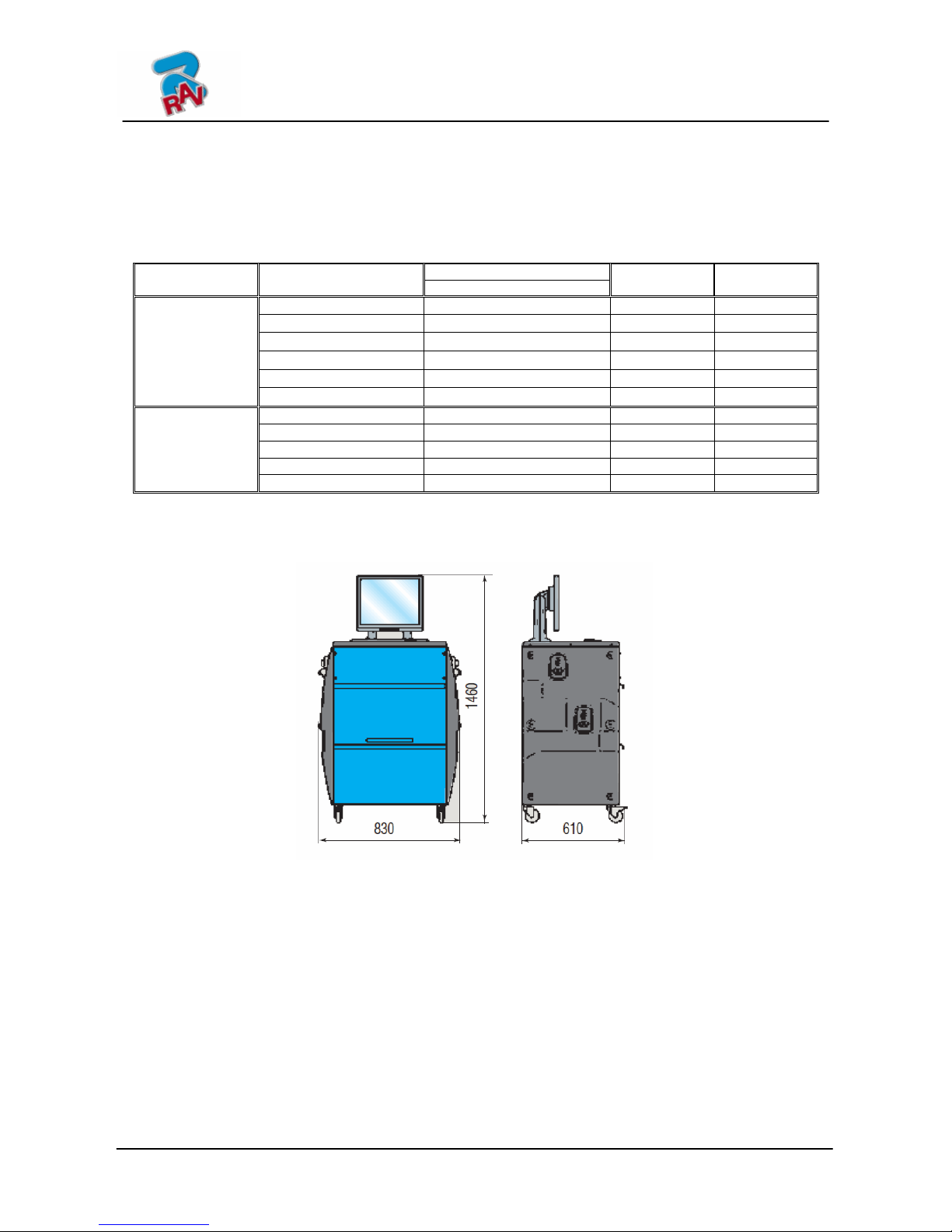

3.4 Overall Dimensions .............................................................................................................................. 6

3.5 Managing PC ........................................................................................................................................ 6

3.6 Detectors............................................................................................................................................... 7

3.6.1 Front Detectors............................................................................................................................................... 8

3.6.2 Rear Detectors RAV TD1780WS..................................................................................................................... 8

3.6.3 Rear Detectors RAV TD1760WS..................................................................................................................... 8

3.6.4 Detector Keypads............................................................................................................................................ 9

3.6.5 LED indicating Levelling and Tolerance during Adjustment.......................................................................... 9

3.7 Clamps................................................................................................................................................ 10

3.7.1 Clamps STDA33............................................................................................................................................ 10

3.7.2 Clamps STDA34............................................................................................................................................ 10

3.7.3 Clamps STDA35............................................................................................................................................ 11

3.7.4 Clamps STDA46............................................................................................................................................ 11

3.8 Rotating Plates.................................................................................................................................... 12

3.8.1 Rotating Plates S110A7 ................................................................................................................................ 12

3.8.2 Electronic Rotating Plates Connected to Detectors with STDS43 Via Radio Transmission......................... 12

4SWITCHING THE MACHINE ON AND OFF.................................................................................. 13

4.1 Switching the Machine On ................................................................................................................. 13

4.2 Switching the Machine Off................................................................................................................. 13

5DETECTORS AUTOMATIC SWITCHING OFF............................................................................. 15

6FLAT BATTERY INDICATION.........................................................................................................15

7PROGRAMME CONFIGURATION .................................................................................................. 16

7.1 DATABASE Groups Configuration...................................................................................................17

8VEHICLE DIAGNOSIS AND ADJUSTMENT ................................................................................. 19

8.1 Introduction Page................................................................................................................................ 19

8.2 Vehicle Make and Model Selection.................................................................................................... 19

8.3 Selected Vehicle Technical Specification Displaying ........................................................................ 22

8.4 Preliminary Operations....................................................................................................................... 23

8.4.1 Vehicle Check Preliminary Operations......................................................................................................... 23

8.4.2 Run-Ou Preparation ..................................................................................................................................... 23

8.5 Run-Out .............................................................................................................................................. 24

8.5.1 Run-Out with Raised Wheels......................................................................................................................... 24

8.5.2 Thrust Run-Out with Automatic Acquisition ................................................................................................. 27

8.5.1 Inclinometer-controlled Run-Out.................................................................................................................. 29

8.6 Measurement Preliminary Operations ................................................................................................ 32

8.7 Detectors Alignment and Levelling.................................................................................................... 33

8.8 Steering Procedure.............................................................................................................................. 34

8.9 Vehicle Diagnosis............................................................................................................................... 35

8.10 Adjustment Preliminary Operations ................................................................................................... 36

8.11 Rear Axle Adjustment ........................................................................................................................ 36