2ICE-LBG-SR

Please read user instruction before initial

operation of the bolt-on lifting point ICE-LBG-

SR. Make sure that you have comprehend

all subjected matters.

Non observance can lead to serious per-

sonal injuries and material damage and

eliminates warranty.

In doubt or in misconception please note

that the German version of this document

is decisive.

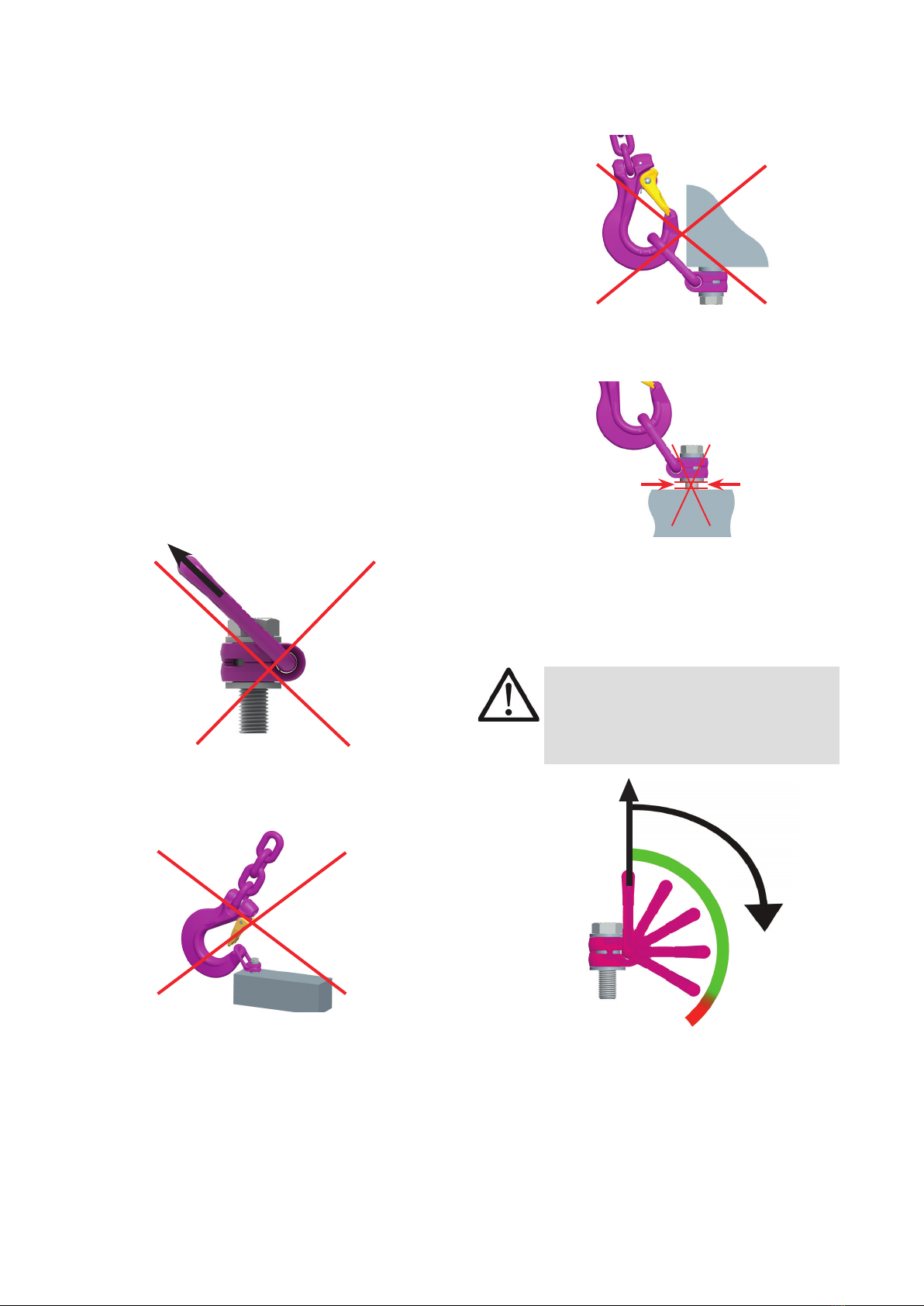

1 Safety instructions

ATTENTION

Wrong assembled or damaged ICE-LBG-

SR as well as improper use can lead to

injuries of persons and damage of objects

when load drops.

Please inspect all ICE-LBG-SR before

each use.

• Remove all body parts (fingers, hands, arms,

etc.) out of the hazard area (danger of crushing

or squeezing) during the lifting process.

• The ICE-LBG-SR must be used only by authorised

and trained people in adherence to BGR/DGUV

regulations 100-500, Chapter 2.8 and, outside

Germany, when observing the relevant specic

national regulations.

• Do not exceed the working load limit (WLL) indi-

cated on the lifting point.

• Only original ICE-Bolts from RUD must be used.

• ICE-LBG-SR must be rotatable in the screwed tight

status through 360 °.

• No technical alterations must be implemented on

the ICE-LBG-SR.

• No people may stay in the danger zone.

• Jerky lifting (strong impacts) should be prevented.

• Always ensure a stable position of the load when

lifting. Swinging must be prevented.

• Damaged or worn ICE-LBG-SR must never be

utilised.

2 Intended use

ICE-LBG-SR lifting points must only be attached at

a load or used at load accepting means.

Their usage is intended to be used as lifting means.

ICE-LBG-SR are suitable to turn and ip loads. Please

observe to this the permissible load directions.

RUD ICE-LBG-SR lifting points can also be used as

lashing points for xing lashing means.

ICE-LBG-SR lifting points must only be used in the

here described operation purpose.

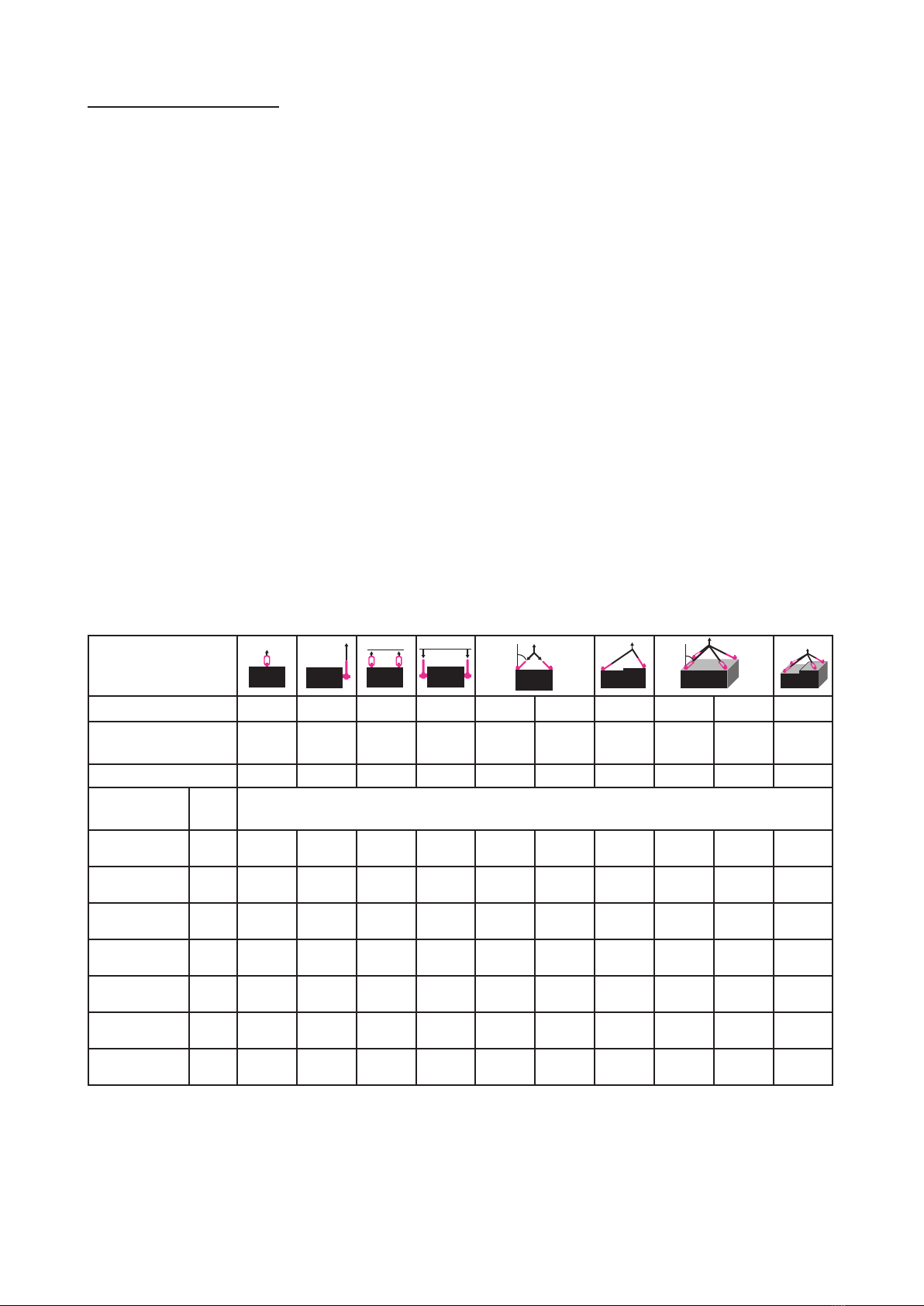

3 Assembly- and instruction manual

3.1 General information

• ICE-LBG-SR can be used for ipping and turning

of loads. Please observe the hints at chapter 3.2

Hints for the assembly.

• Eects of temperature:

The WLL of the ICE-LBG-SR lifting points must be

reduced as follows:

-40°C up to 100°C no reduction

100°C up to 200°C minus 15 % (212 up to 392°F)

200°C up to 250°C minus 20 % (392 up to 482°F)

250°C up to 300°C minus 25 % (482 up to 572°F)

Temperatures above 300°C (572°F) are not per-

mitted!

Please observe the maximum usage temperature

of the supplied nuts (optionally):

• Lock nuts acc. to DIN EN ISO 7042 (DIN 980)

must be used to max. +150° C (302°F)

• Collar nuts acc. to DIN 6331 can be used up

to +300°C (572°F). In addition to that observe

the reduction factor

• RUD-Lifting points must not be used under chemi-

cal inuences such as acids, alkaline solutions and

vapours e.g. in pickling baths or hot dip galvanising

plants. If this cannot be avoided, please contact the

manufacturer, indicating the concentration, period

of penetration and temperature of use.

• The place where the ICE-LBG-SR lifting points are

xed should be clearly marked with colour.

• RUD ICE-LBG-SR lifting points from RUD are

supplied with a crack test inspected hexagon bolt

(length up to Lmax, see table 3).

M8-M24: ICE-Bolt

M30: 10.9 bolt

ATTENTION

Use only the appropriate strength class of bolt, for

each specic size. For sizes M8-M24, only original

RUD-ICE-Bolt must be used.

• Original bolts (ICE bolt and 10.9 bolts) are available

as a spare part from RUD.

• When using 10.9 bolts of the size M30 from other

suppliers, make sure that they have been 100 %

inspected in regards of cracks. A written conrma-

tion of the absence of cracks must be added to the

documentation.

The middle notch toughness at the lowest appro-

ved use temperature must be at least 36 J. This

is required for the test principles for GS OA 15-04

lifting points.

HINT

The dismantling / assembling for the ex-

change or inspecting of the bolt may only be

executed by a competent person (compare

with Section 3.4 Dismantling / Assembling

the RUD bolt).

• Versions

• The metric vario length can either be equipped

with a washer and a crack detected nut acc. to

DIN EN ISO 7042 or with a collar nut acc. to

DIN 6331.