At outdoor sites or in case of a high corrosion hazard, all

weld seams should only be carried out as continuous, fillet

weld. The HY-weld of the LRBS fulfills this specification.

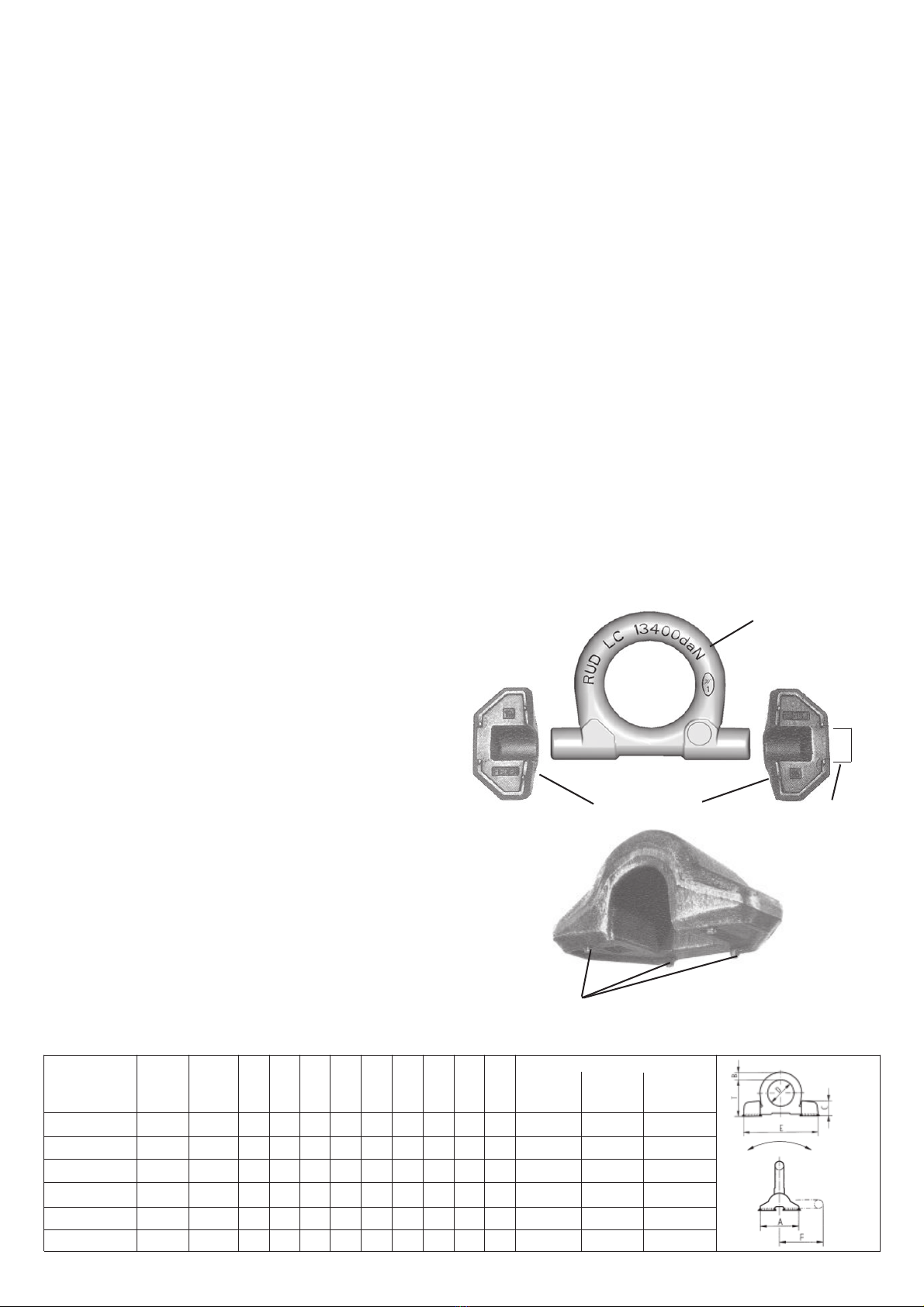

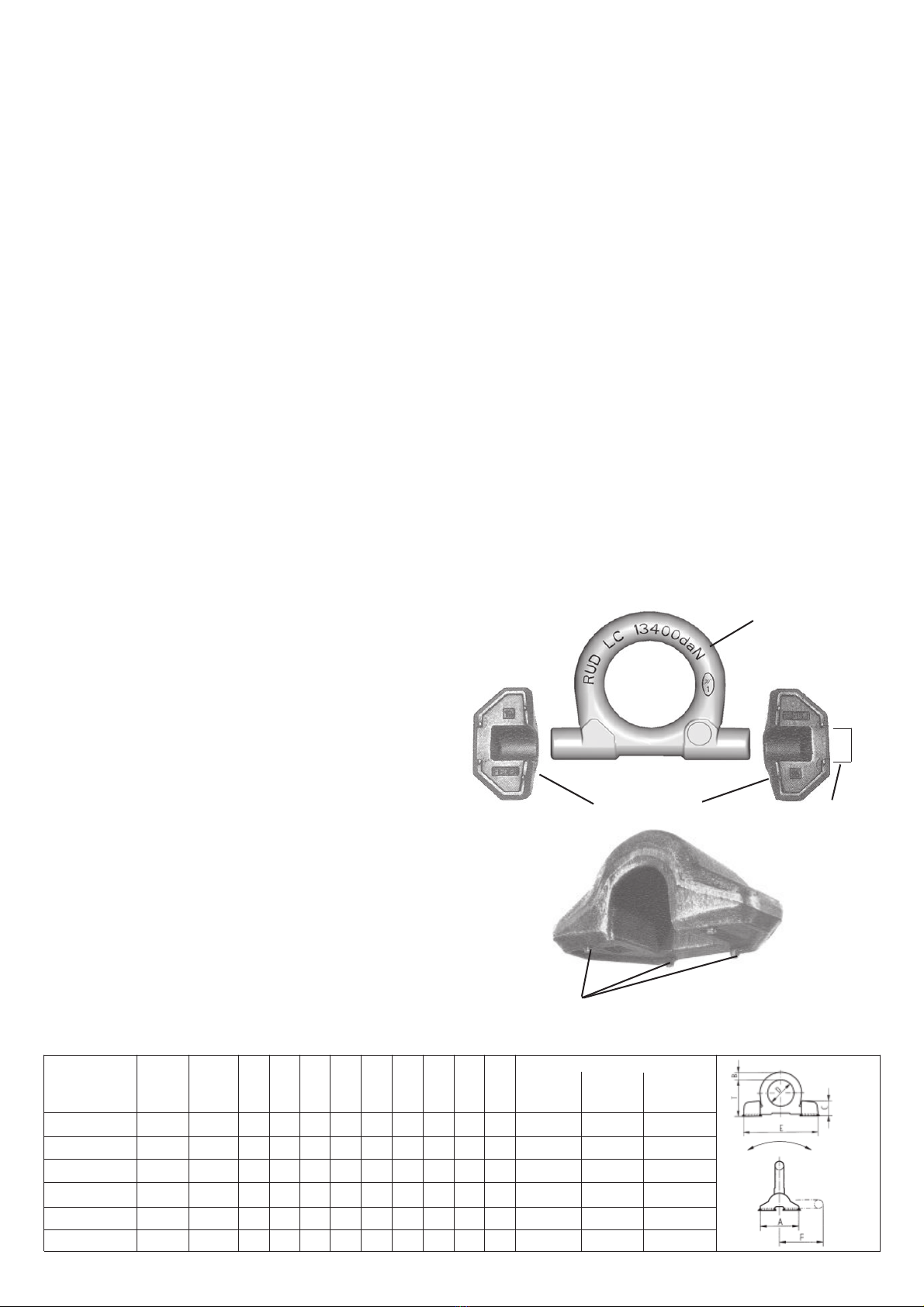

The distance lugs assist in achieving the correct air gap for

the root of seam weld (approx. 3 mm, or 1/8") Lugs must

not be removed!

10. After welding, or sooner if conditions dictate, an annual

inspection should be undertaken by a authorized person to

check the continuance of the appropriateness.

Inspection criteria concerning paragraph 2 and 10:

•Completeness of Lashing Point

•Complete and readable marking of Lashing Capacity

as well as manufacturer sign

•Deformation at supporting structures like Basic

Components and Lashing Rings.

•Mechanical damage like strong notches, particully

in areas with tensile stress

•Reduction of cross sectional diameter caused by wear

> 10 %

•strong corrosion (pittings)

•Cracks on supporting structures

•Cracks or any other damage of the weld seam

Warning: Failure to read, understand and follow the

instructions, Lashing Capacity and specifications in this and

other RUD publications could result in serious injury or

property damage!

User Instruction

1. Usage only by authorized and trained persons.

2. Check Lashing Points regular and before every usage

in regard of cracks at weld seam, strong corrosion, wear,

deformations etc.

3. Design location of Lashing Points in such a way that

the base material can withstand lead in forces without

deformation. The weld on material must be free of

impurities, oil and paint.

Material of weld blocks S355J2+N (1.0570+N (St52-3))

B.S. 4360.50 D or AISI 1019

4. The quantity and the arrangement of the Lashing

Points on vehicles have to be determined acc. EN 12640

or EN 75410 (for RORO traffic; Roll-On - Roll-Off) as long

as the vehicles are not designated acc. their design and

mechanism for the transport of specific goods with special

demands for load securing. The Lashing Points shall be

arranged as wide as possible to use the full loading area

and they should not protrude in steady position. Execute

the position of the Lashing Points with the load in such a

way that unacceptable stress like twisting or tilting will be

avoided.

Warning: Lashing Points must not be used for Lifting

of loads.

5. Determine the required, permitted Lashing Capacity

acc. EN 12 195-1 „Load securing devices on road

vehicles“ - calculation of Lashing Capacities and acc.

VDI 2700. RUD-Lashing Points are marked at the

welding block with the permitted lashing capacity

„LC“ in daN.

6. The Lashing device must be free moveable within the

LRBS. During hang up and unhinge of the lashing devices

there must no crush, cutting or traps occur for the

handling.

7. Suitability of temperature use: RUD-Lifting points LRBS

are suitable for the temperature range from -20°C up to

400°C. For the use within the following temperature range,

the WLL must be reduced by the following factors:

200°C up to 300°C: by -10 % and

300°C up to 400°C: by -25 %

The lifting points LRBS can be stress-relieved one-time in

an unloaded condition, together with the load (e.g. welded

construction): Temperature < 600°C (1100°F, without a

reduction of the WLL).

The evidence of the suitability of the used weld metal must

be mentioned by the respective filler material manufacturer.

8. Please make Lashing Point easy visible by using a

contrasting colour as paint.

9. Weld seam arrangement (continuous HY) fulfills the

following requirements: DIN 18 800 Structural steel

elements specifies:

welding block

Lashing Ring

Type pem. Part.-No.:

LC weight A B C D EFTO Q

daN kg LRBS Lashing Ring welding block

LRBS 8000 8000 0.9 62 16 28 48 135 71 65 19+0,5 77+1 7993148 7993477 7992004

LRBS 13400 13400 2.1 88 20 39 60 170 92 84 25+0,5 101+1 7993149 7993478 7992005

LRBS 20000 20000 3.0 100 22 46 65 195 100 95 30+0,5 106+1 7993150 7993479 7992007

LRBS 32000 32000 6.9 130 30 57 90 266 134 127 38+0,5 147+1 7993151 7993480 7992008

chart 1

Pivots

180 °

water outlet

distance lugs approx. 3 mm

(1/8", 0.125 inch)