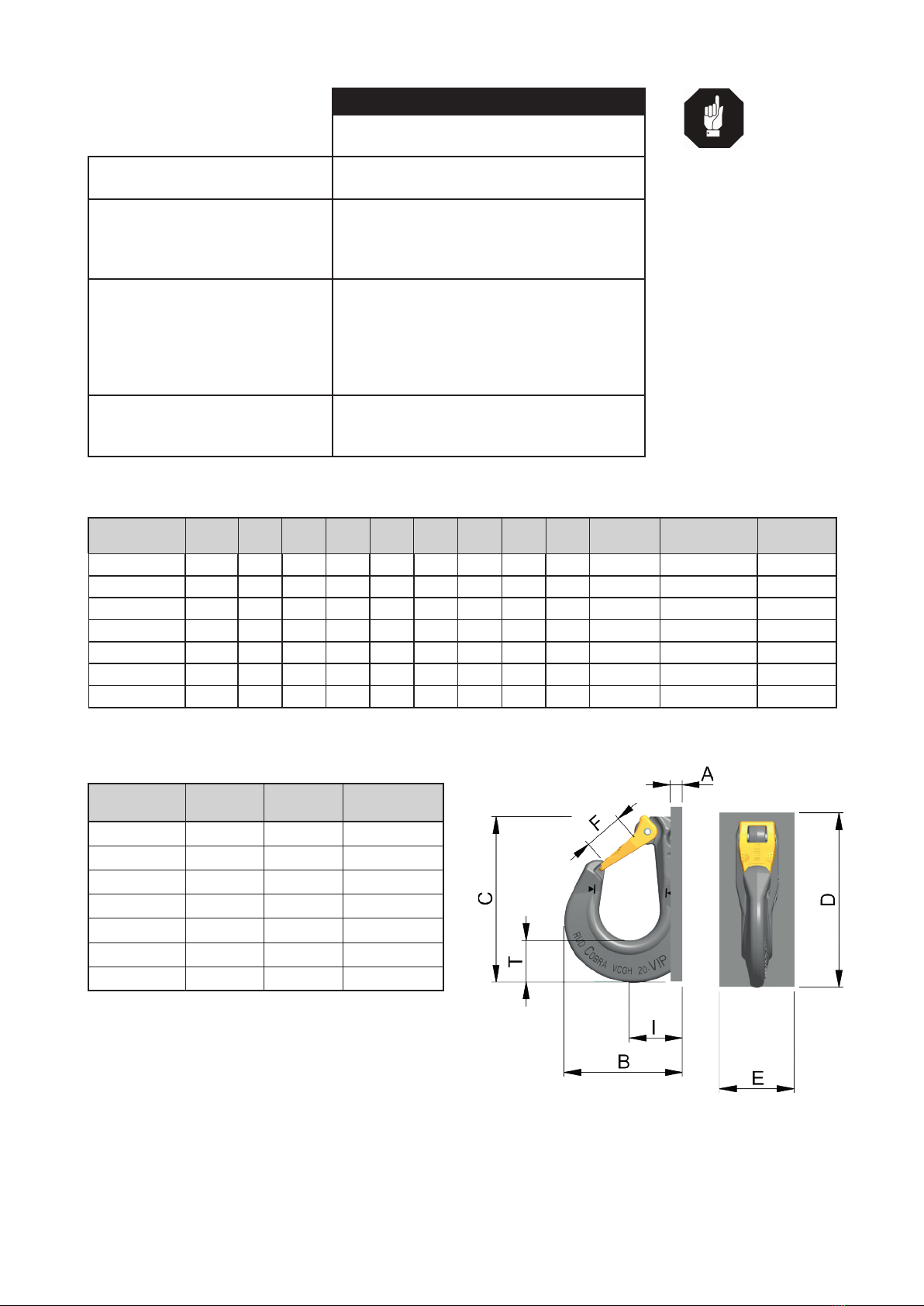

2VCGH-S

Before initial usage of the RUD VCGH-S,

please read carefully the safety instruc-

tions. Make sure that you have understood

all subjected matters.

Non-observance can lead to serious per-

sonal injuries and material damage and

eliminates warranty.

1 Safety instructions

ATTENTION

Wrong positioned or damaged weld-on

lifting points as well as improper use can

lead to injuries of persons and damage at

property, when load falls down.

Please check all lifting points carefully

before every usage.

• Remove all body parts (fingers, hands, arms,

etc.) out of the hazard area (danger of crushing or

squeezing) during the lifting process.

• RUD Lifting points VCGH-S must only be used

by instructed and competent persons considering

DGUV 109-017, and outside Germany noticing the

country specic statutory regulations.

• Do not exceed the working load limit (WLL) indica-

ted on the lifting point.

• No technical alterations must be implemented on

the VCGH-S.

• No people may stay in the danger zone.

• Jerky lifting (strong impacts) should be prevented.

• Always ensure a stable position of the load when

lifting. Swinging must be prevented.

• Damaged or worn VCGH-S must never be utilised.

2 Intended use

RUD Lifting points VCGH-S must only be used for the

assembly at the load or at lifting means.

They are designed and intended to attach lifting

means.

RUD Lifting points can also be used as lashing points

to attach lashing means.

RUD Lifting points must only be used in the hereby

specied case of operation.

3 Assembly- and instruction manual

3.1 General information

• Capability of temperature usage:

RUD Lifting points VCGH-S are suitable for the

temperature range from -20°C up to 400°C.

For the use within the following temperature range,

the working load limit (WLL) must be reduced by

the following factors:

-20°C up to 200°C no reduction

200°C up to 300°C minus 10 %

300°C up to 400°C minus 25 %

Temperatures exceeding 400°C are prohibited!

• RUD Lifting points VCGH-S must not be used

with aggressive chemicals such as acids, alkaline

solutions and their vapours.

• Please mark mounting position of lifting point with

a coloured contrast paint for better visibility.

3.2 Hints for the assembly

Basically essential:

• The material construction to which the lifting

point will be attached should be of adequate

strength to withstand forces during lifting wit-

hout deformation. The weld-on material must

be suitable for welding and the contact are-

as must be free from dirt, oil, colour, ect.

The material of the forged welding block is:

S355J2 (1.0577+N (St52-3))

• The position of the lifting points must be carried

out in such a way that unintended movement like

turning or ipping will be avoided.

• For single leg lifts, the lifting point should be

vertically above the centre of gravity of the load

• For two leg lifts, the lifting points must be

equidistant to/or above the centre of gravity

of the load.

• For three and four leg lifts, the lifting points

should be arranged symmetrical around the

centre of gravity, in the same plane if possible.

• Load symmetry:

Determine the necessary WLL of each lifting point

for a symmetrical load by using the following phy-

sical calculation formula:

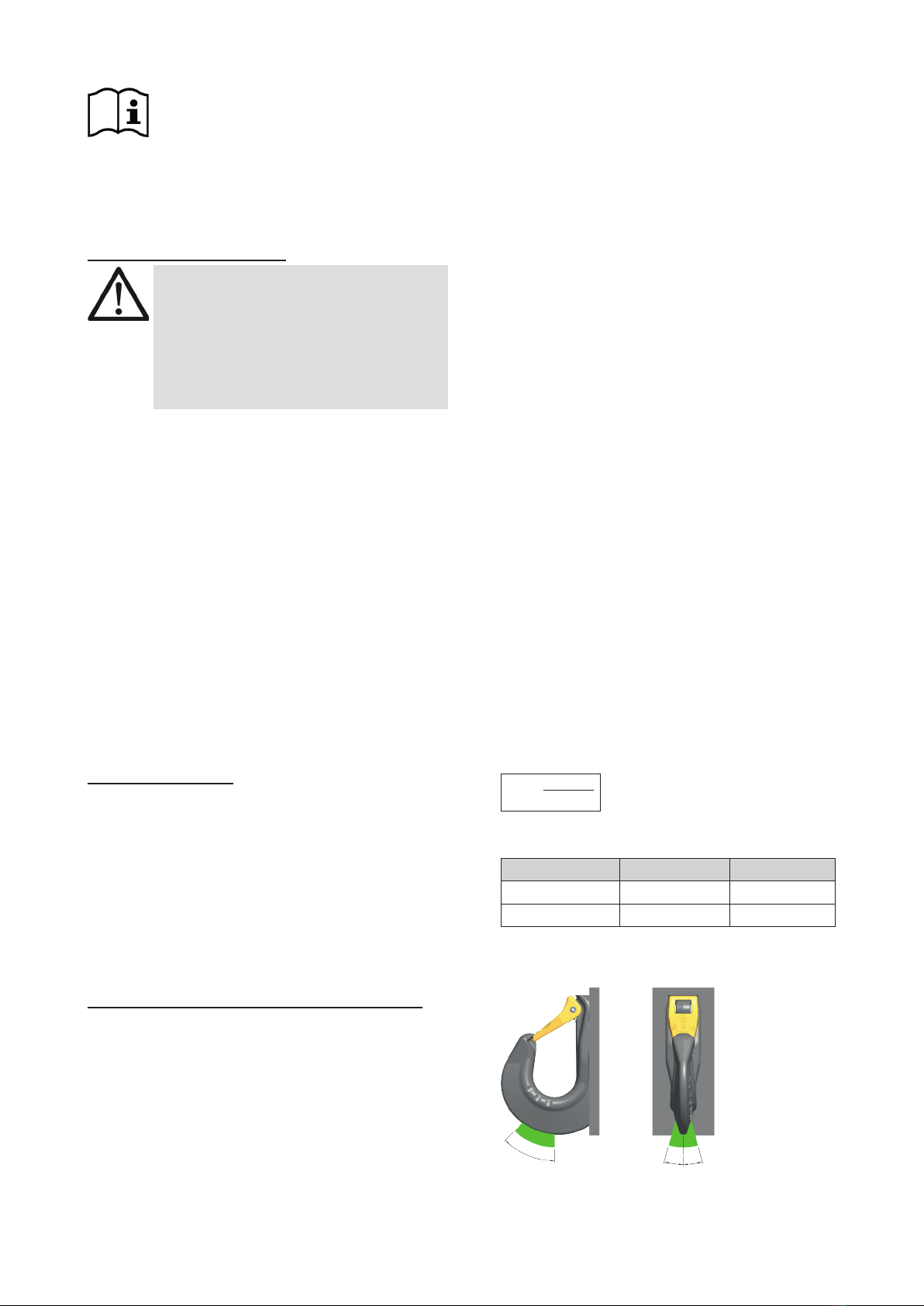

WLL = necessary WLL of lifting point /

single strand (kg)

G = weight of load (kg)

n = number of load bearing strands

ß = inclination angle of single strand

WLL=G

n x cos ß

Number of load bearing strands:

Symmetric Unsymmetric

two leg 2 1

three / four leg 3 1

Table 1: Load bearing strands (compare to Table 2)

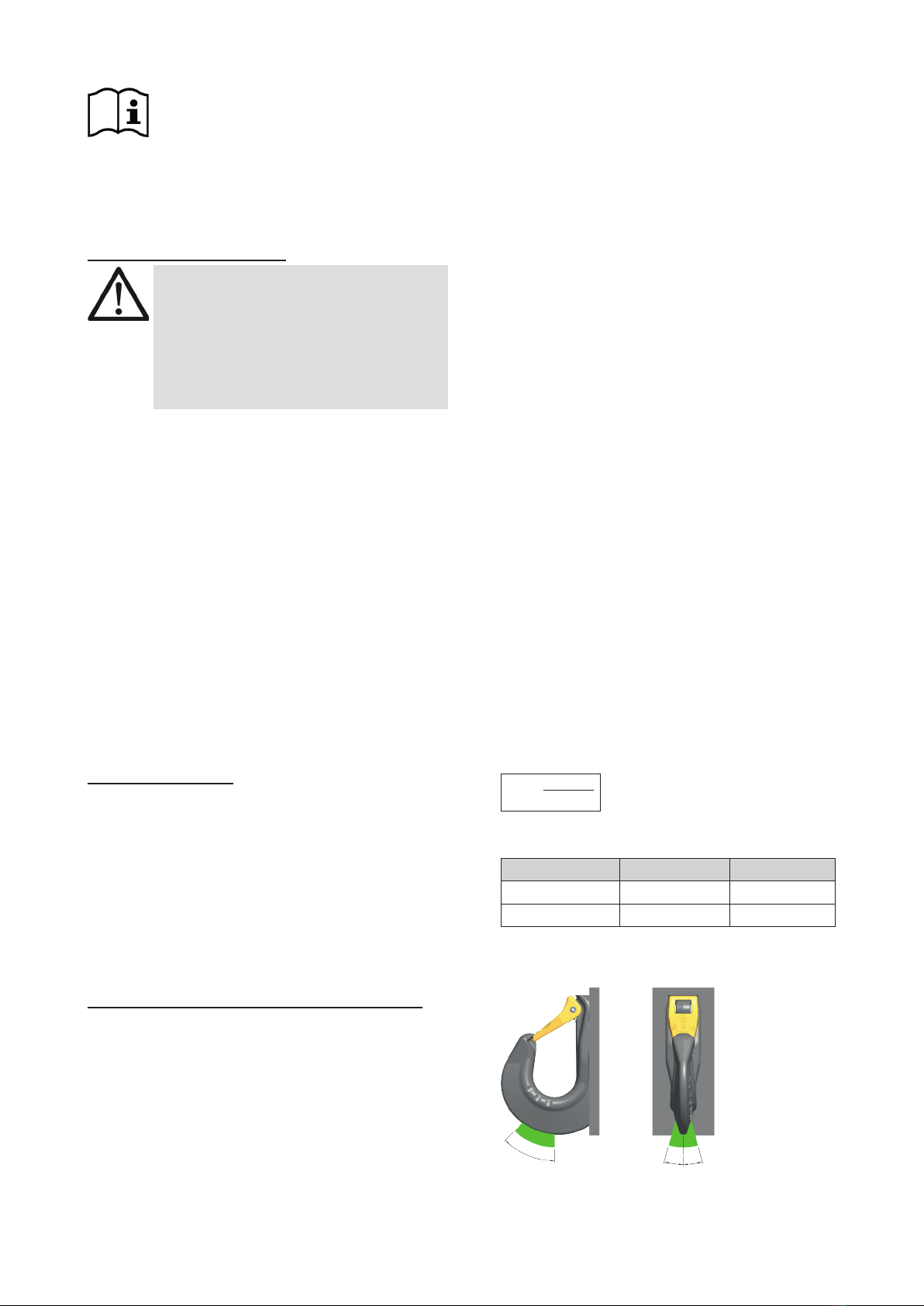

• Arrangement of the Excavator hooks: The instal-

lation should be in the direction of pull.

45°

15°

15°

Pic. 1: Possible use area