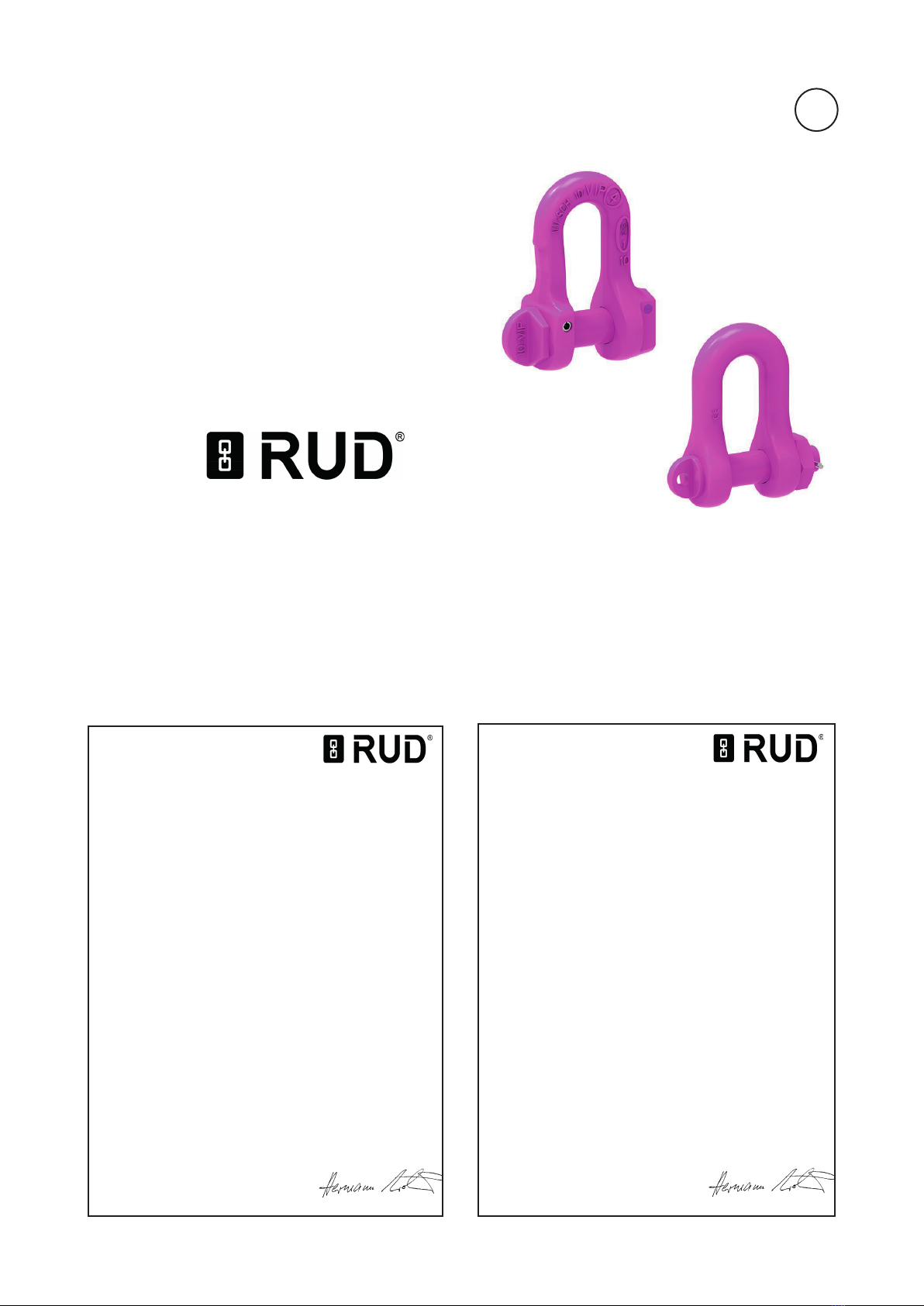

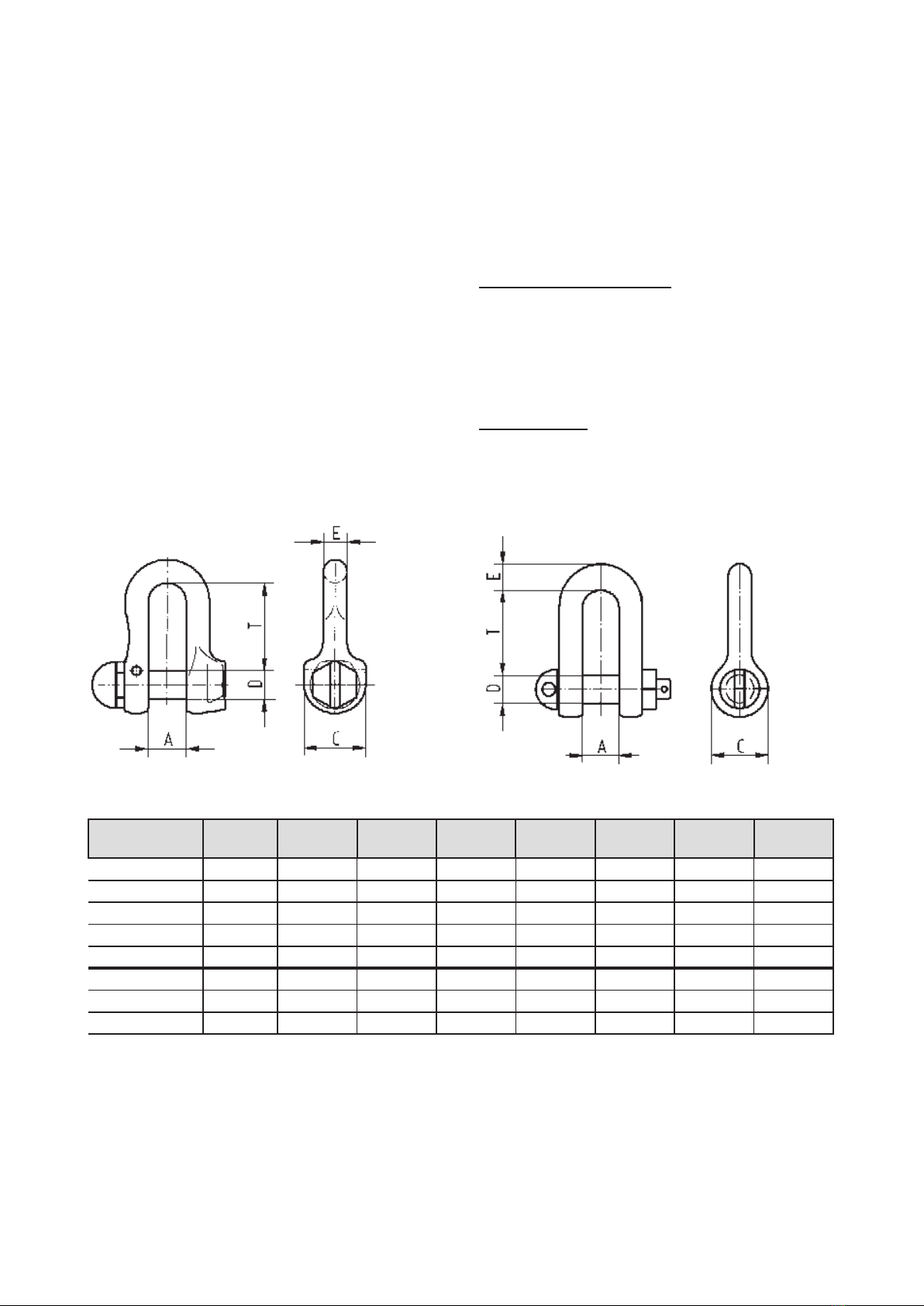

2VV-SCH / VC-SCH

Please read user instruction carefully

before initial operation of VV-SCH

and VC-SCH.

Make sure to understand all volumes.

Non-observance of this user`s manu-

al can lead to serious physical injury

and property damage and eliminates

warranty.

In doubt or in misconception please note that the

German version of this document is decisive.

This user instruction is valid in addition to the safety

instructions for RUD Sling chains, RUD Ref. No.

7101649

1 Application and warning information

ATTENTION

Wrong assembled or damaged lifting me-

ans as well as improper usage can lead

to physical injury and damage of property

while failing.

Inspect lifting means before each use ca-

refully!

• Keep all body parts like ngers, hands, arms, etc.

out of the hazardous area during the lifting operation.

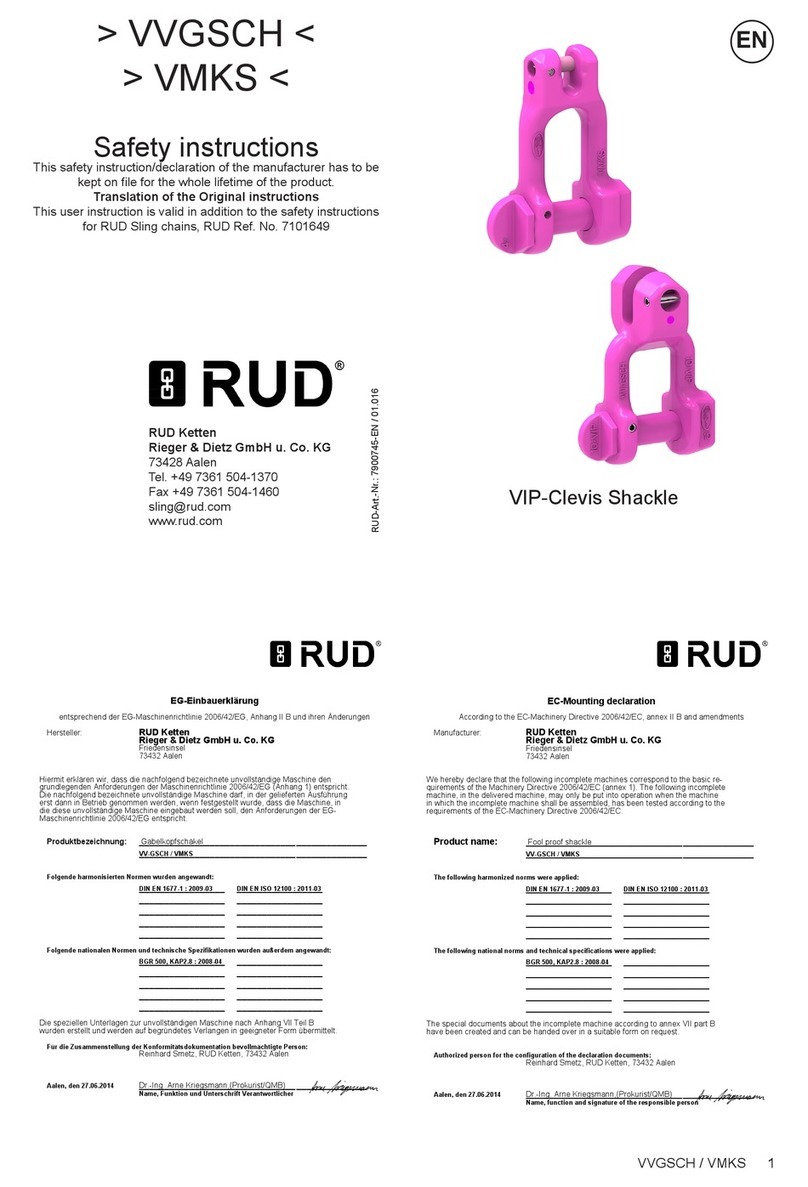

• The VIP fool proof and the VIP-VC shackles must

only be used considering the DGUV 109-017,

and outside Germany acc. to the coun-try specic

requirements.

• Consider extreme circumstances or schock loading

when choosing the utilised product.

• Side loading is due to the design not allowed.

• At the VC-SCH the weld-on nut must not be re-

moved.

• No technical alterations must be implemented on

the VIP fool proof and the VIP-VC shackles.

• No people may stay in the danger zone.

• Damaged or worn VIP fool proof and VIP-VC

shackles must never be utilised.

2 Intended use

Foolproof VIP and VIP VC-shackles are high-strength

straight shackles within a range from 1.5 to 31.5 t

WLL.

They can be used as an end component for chain

slings or lugs. Side load ist not allowed.

The fool proof VIP and VIP VC-shackles must only

be used in the here described usage.

3 Installation and user information

3.1 General information

• Capability of temperature usage:

When used in temperatures higher than 200°C

the WLL of the VIP foolproof and VIP-VC-shackles

must be reduced as follows:

• -40°C up to 200°C no reduction

• 200°C up to 300°C minus 10 %

• 300°C up to 400°C minus 25 %

• Temperatures above 400°C are prohibited!

• VIP foolproof and VIP-VC shackles must not be

used together with aggressive chemicals, acids

and vapours.

3.2 Hints for the assembly

• VIP chains can be connected to shackles either

with the VIP coupling or with an end link VA/VB.

• Please pay attention during selection and assembly

to the correct sizing.

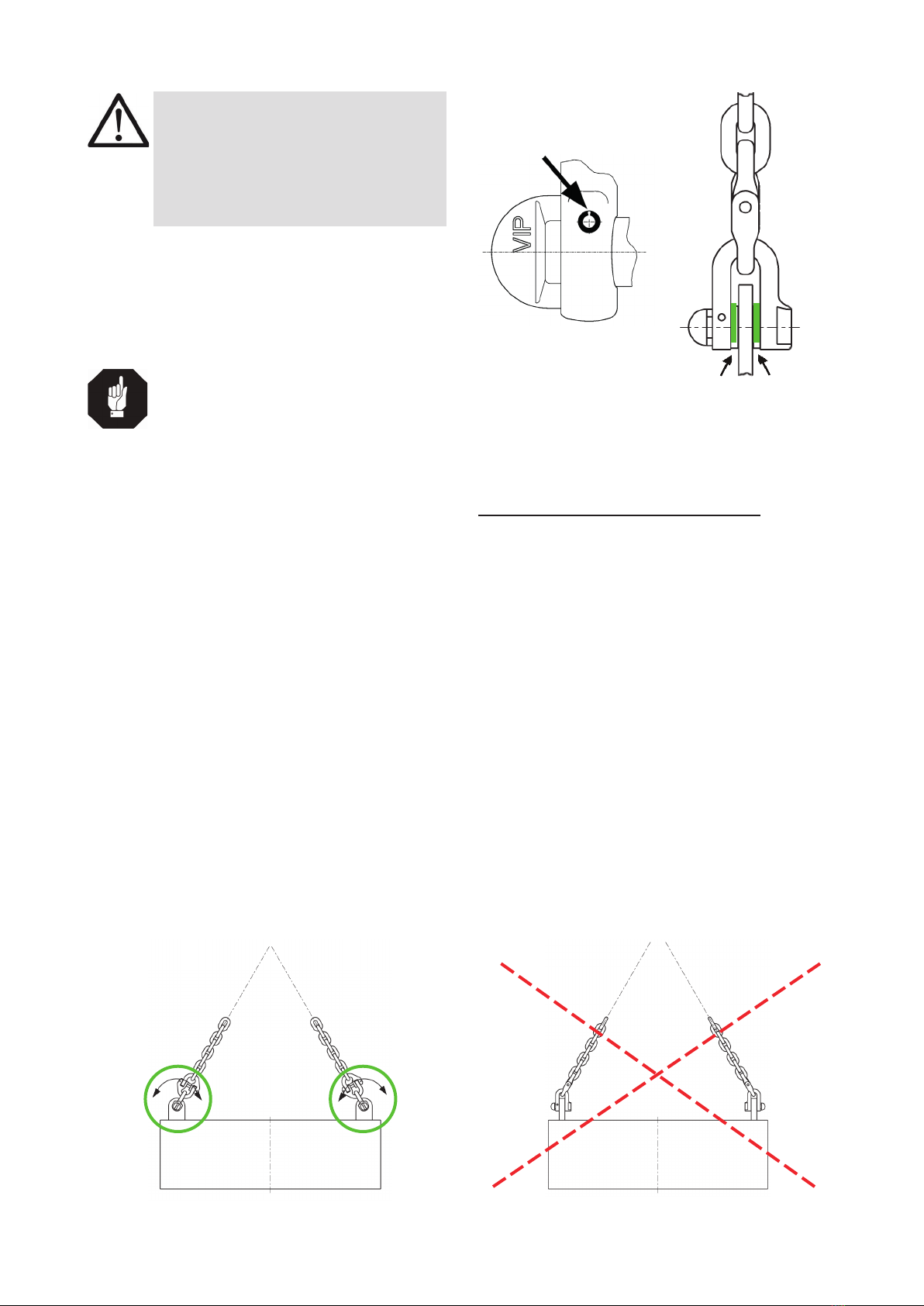

• Screw shackle bolt proper into the eye of the

shackle and secure it as follows:

• VC-SCH: by assembly of cotter-pin

• VV-SCH: By punching in the securing sleeve.

Pay attention to the slash (see picture 1)!

The shackle bolt of the VV-SCH is pivot moun-

ted.

• To avoid single sided loading, washers on

both sides of the bolt are allowed to be used

(see picture 2).

The inside width must not be reduced by welded-in

washers, distance parts or bending of the legs. All

these damages are leading to adverse consequen-

ces of the shackle properties.

Common rule:

• Assemble only shackle components with H1-10

embossement.

• Pay attention to the correct sizing of the connecting

components.

• Use only original RUD spare parts.

3.3 Sequence of assembly

1 Insert connecting part into the shackle.

2 Screw shackle bolt in.

3 Assemble cotter-pin respectively securing sleeve.

4 Check nally the correct assembly (see chapter 4

Inspection / repair / disposal).

3.4 Hints for the usage

• Make sure before loading that the shackle bolt is

fully engaged. This is the case when the end of the

shackle bolt at the thread is in line with the eye of

the shackle and the bolt can be turned in the bus-

hing easy. When shackle is permanently or

more than once used, please secure bolt by using

a hammer to punch the roller pin.

• Control frequently and before each operation the

total lifting mean in regard of ongoing ability, strong

corrosion, wear, deformation etc. (see chapter 4

Inspection / repair / disposal).