RDC6445GT5 Laser cutting system hardware user manualV1.1

深圳市睿达科技有限公司

Contents

Chapter 1 Overview ...............................................................................................错误!未定义书签。

1.1 RDC6445GT5 Control System Brief Introduction............................................................................2

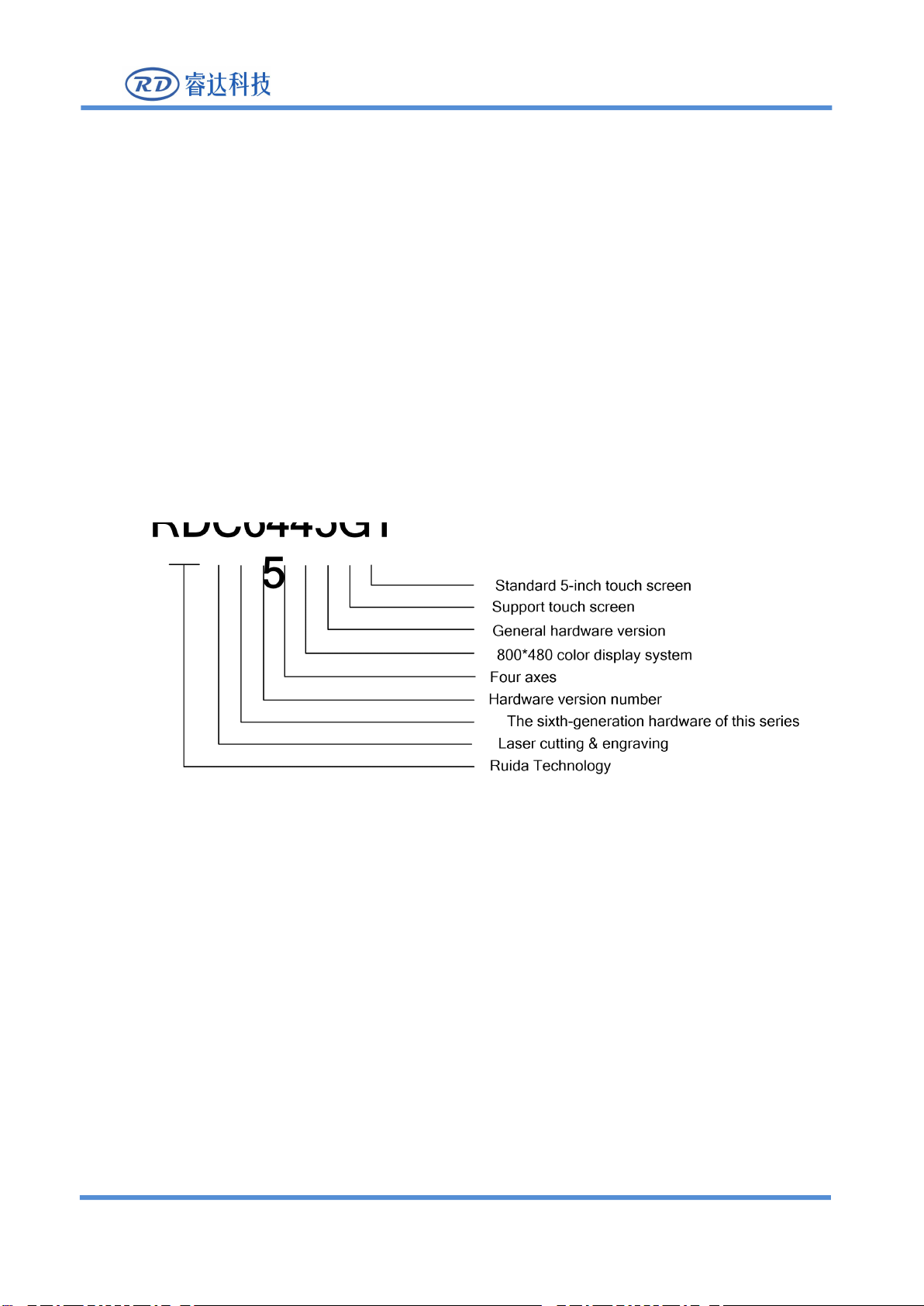

1.2 RDC6445GT5 Controller Model Description...................................................................................2

1.3 Comparison of Controller Performance....................................................... 错误!未定义书签。

Chapter 2 Installation Size.........................................................................................错误!未定义书签。

2.1 Mainboard Installation Size.......................................................................... 错误!未定义书签。

2.2 Touch screen Installation Size........................................................................错误!未定义书签。

Chapter 3 Physical pictures and Interfaces Overview............................................ 错误!未定义书签。

3.1 Mainboard Physical pictures..............................................................................................................7

3.2 Touch screen Physical pictures.......................................................................................................... 8

3.3 Control System Electrical Connectivity Diagram............................................................................... 9

Chapter 4 Mainboard Interface Signal Description.................................................. 错误!未定义书签。

4.1 Main Power Interface CN0.............................................................................. 错误!未定义书签。

4.2 Mainboard and touch screen connection port HMI........................................................................11

4.3 U Disk Interface U............................................................................................ 错误!未定义书签。

4.4 PC-USB Interface..............................................................................................错误!未定义书签。

4.5 Ethernet Interface............................................................................................................................ 11

4.6 General/Dedicated Output Port CN1...............................................................................................12

4.7 General/Dedicated Input Interface CN2..........................................................................................12

4.8 Four-Axis Limit Input Interface CN3/CN4........................................................................................ 13

4.9 X/Y/Z/U Four-Axis Driver Interface AXIS_X~AXIS_U........................................................................14

4.10 Laser Power Supply Control Interface CN5/CN6.............................................................................. 14

Chapter 5 Examples of Laser Power Interface.......................................................... 错误!未定义书签。

5.1 Overview.......................................................................................................错误!未定义书签。

5.2 Glass Tube Laser Power Supply Wiring Diagram..........................................错误!未定义书签。

5.3 RF CO2 Laser Source Wiring Diagram...........................................................错误!未定义书签。

Chapter 6 Examples of Stepper Motor Driver Interface........................................错误!未定义书签。

6.1 Overview.......................................................................................................错误!未定义书签。

6.2 Driver Connection Diagram.......................................................................... 错误!未定义书签。

Chapter 7 IO Port Wiring Examples........................................................................错误!未定义书签。

7.1 Input Port......................................................................................................错误!未定义书签。

7.2 Output Port.....................................................................................................错误!未定义书签。

Chapter 8 HMI Operation Instructions.................................................................. 错误!未定义书签。

8.1 Introduction.................................................................................................. 错误!未定义书签。

8.2 Main Interface Functions..............................................................................错误!未定义书签。

8.2.1 Main Interface...........................................................................................................................28

8.2.2 Speed Settings...........................................................................................................................29

8.2.3 Power Settings.......................................................................................................................... 30

8.3 File Parameters............................................................................................. 错误!未定义书签。

8.3.1 Layer Information......................................................................................................................31