YOUR BATTERY

Please make sure your battery is in good condition

and no smaller than 750CCA. Using a battery smaller

than this could cause damage to your winch motor or

solenoid and void yourwarranty.

GEARBOX ROTATION

If you need to rotate your gearbox please

follow the instructions included, or visit

www.runvawinch.com.au/support

FITTING YOUR WINCH

Bolt the winch into your winch bar or other winch rated

plate as per that manufacturer instructions.

Runva is not able to provide fitting instructions or

technical support that is specific to your vehicle or bar.

If you are unsure how to fit your winch we recommend

going to a 4X4 specialist or installer.

For bolt torque settings visit the Support page

on www.runvawinch.com.au/support

WIRING YOUR WINCH

Your winch motor has clearly marked colour coded

insulators on all the terminals for easy wiring.

Simply attach the corresponding colour leads to the

corresponding terminals. The two longer 1.8M leads

supplied are your main powerleads.

The long red power lead that runs from the control box

connects to one of the terminals

on the isolator switch.

THANK YOU FOR CHOOSING ONE OF OUR PREMIUM EDITION WINCHES

Make sure you connect the earth lead from the winch

motor directly to the negative terminal on your vehicle

battery. (Connecting it to the chassis instead of to the

battery could cause damage to your winch motor or

solenoid and void your warranty).

If you have a smart alternator or vehicle which does not

allow the winch being connected directly to the negative

terminal on the battery, the winch earth lead will need to

be bolted to the battery earth on the chassis instead of

directly to the battery itself.

The thin black cable from the control box attaches

to the same terminal on the winch motor as the main

earthlead.

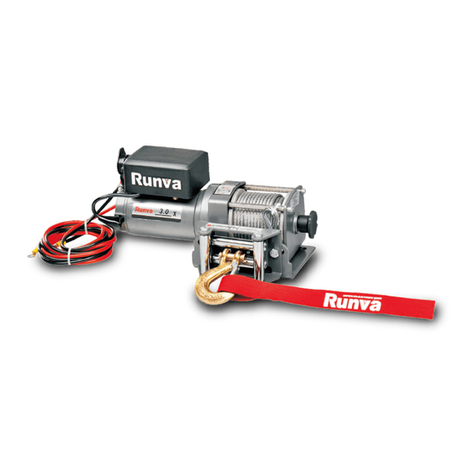

POWER ISOLATOR

The winch package you received is supplied with

a power isolating switch and easy to use mounting

bracket. With the main red power cable now attached

to one of the terminals on the isolator (as described

on point 4), the shorter 30cm power lead connects to

the other other terminal on the isolator and then to the

battery positive terminal. With the key in and turned on,

the power to the winch is live. When the key is turned to

the o position all power is cut o.

Theisolator must be installed. Theswitch must remain

in the OFF position with key removed until you need to

use your winch. Store the key securely in yourvehicle.

USING YOUR WINCH

Once your winch is fitted and wired, it is ready for

use. You can power your winch either by the plug in

handheld remote or the wireless remote.

Every recovery is dierent and all carry potential

risks. There is no manual on "how to do a recovery"

for this exact reason as no two recoveries would be

the same. You will need to understand basic recovery

techniques in order to safely use your winch. If you

are new to the 4X4 world joining a club would be

useful to learn all the skills. There are also many

videos on YouTube which go over using a winch and

recovery techniques in dierent scenarios.

Make sure to use the correct and safe recovery

equipment with your winch

BASIC MAINTENANCE

Make sure you run your winch cable/rope in and

out at least once, every 4 - 6 weeks. Failure to

do this will void your warranty. Winches do not

like to sit unused for long periods of time.

Also regularly check that all connections on

the winch motor is clean and tight. Refer to

www.runvawinch.com.au/support for more

information on the maintenance requirements.

Also refer to the Runva Warranty policy.

EXTENDING YOUR POWER LEADS

You can replace your power leads with longer ones

if required for your setup. Make sure to also increase

the diameter of the lead to avoid damaging your

winch due to potential voltage drop.

HIDING YOUR CONTROL BOX

If you choose to hide your control box we can

supply a remote extension plug so you can still use

your handheld remote. Please visit our website for

moreinformation.

PLEASE READ THIS CAREFULLY BEFORE YOU GETSTARTED

MAIN RED POWER

LEAD (1.8M) TO

CONTROL BOX

SHORT RED POWER

LEAD (30CM) TO

VEHICLE BATTERY