4

Airflow-IQ Start-up & Commissioning Guide

IMPORTANT: Only a qualified service technician should install this system. To avoid unsatisfactory operation

or damage to the product, strictly follow the instructions provided and do not substitute parts. Damage to the

product resulting from not following the instructions or using unauthorized parts may be excluded from the

manufacturer’s warranty coverage.

IMPORTANT: In addition to these instructions, the installation contractor shall comply with all local and

International codes and standards to ensure proper and safe installation.

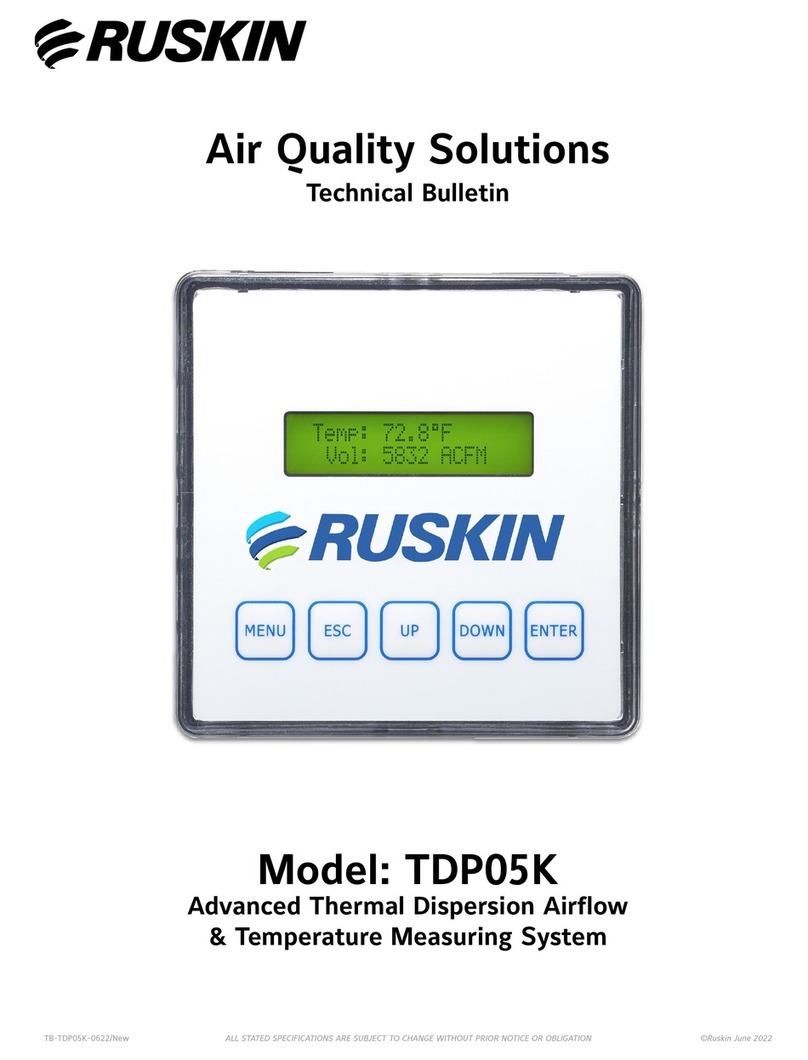

Software Configuration Information for Commissioning:

After the installation described in this document is complete, please refer to the TDP05K Technical Bulletin for

information regarding configuration options.

The Technical Bulletin document can be viewed or downloaded at this location:

http://www.ruskin.com/catalog/servefile/id/6767.

The Technical Bulletin document can also be accessed via this QR Code:

Confirm power requirements before wiring actuator. Ruskin is not responsible for any damage to, or failure of

the unit caused by incorrect field wiring.

AD-1252 Thermal Dispersion Probe Airflow Measuring System Installation Instructions 1

preliminary - this information may change

Applications

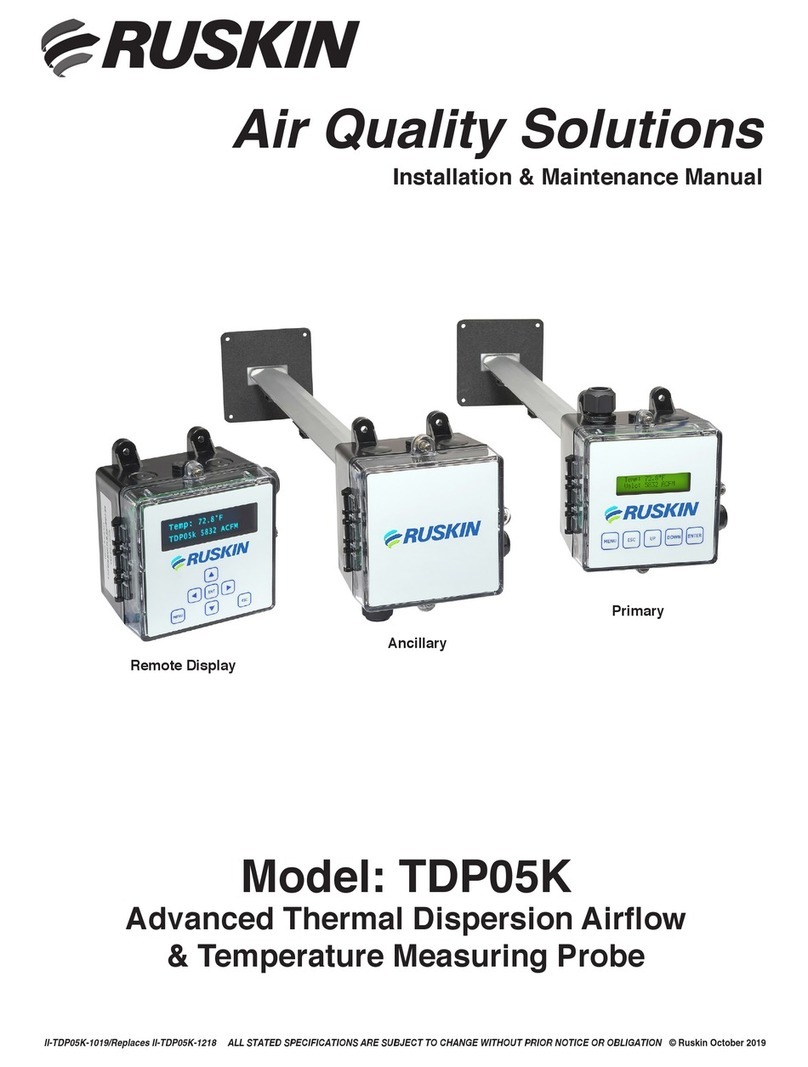

The AD-1252 Thermal Dispersion Probe Airflow

Measuring System is an air-measurement device that

uses thermal dispersion technology to measure the

airflow velocity and temperature in duct and plenum

applications. Insertion probes are typically installed in

retrofit applications but may also be specified on new

construction projects.

The product may be used in rectangular, oval or round

applications when installed in accordance with this

installation manual. Use behind a rain hood, in front of

an outside air damper, return air duct, downstream of a

fan discharge or in the exhaust duct.

North American Emissions Compliance

United States

Canada

Installation

Mounting

The sensor density is based on extensive lab testing to

optimize the accuracy of the electronic controller.

When installing the thermal dispersion probe(s), use

the Square Duct Mounting and Round Duct Mounting

sections to determine the proper spacing between

each probe within the opening. Contact your local

Johnson Controls® representative if you have

questions regarding a particular application.

This equipment has been tested and found to

comply with the limits for a Class A digital device

pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection

against harmful interference when this equipment is

operated in a commercial environment. This

equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in

accordance with the instruction manual, may cause

harmful interference to radio communications.

Operation of this equipment in a residential area is

likely to cause harmful interference, in which case

the user will be required to correct the interference

at his/her own expense.

This Class (A) digital apparatus meets all the

requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique de la Classe (A) respecte

toutes les exigences du Règlement sur le matériel

brouilleur du Canada.

ARNING: Risk of Electric Shock

nnect power supply before making

ectrical connections. Contact with

nents carrying hazardous voltage can

electrical shock and may result in

severe personal injury or death.

IMPORTANT: Only a qualified service technician

should install this system. To avoid unsatisfactory

operation or damage to the product, strictly follow

the instructions provided and do not substitute parts.

Damage to the product resulting from not following

the instructions or using unauthorized parts may be

excluded from the manufacturer’s warranty

coverage.

AD-1252 Thermal Dispersion Probe Airflow Measuring

System

Installation Instructions Part No. 44-1122-2, Rev. -

Issued June 30, 2009

Software Configuration Information for Commissioning:

After the installation described in this document is complete, please refer to the TDP05K Technical Bulletin

for information regarding conguration options.

The Technical Bulletin document can be viewed or downloaded at this location:

http://www.ruskin.com/catalog/servele/id/6767.

The Technical Bulletin document can also be accessed via this QR Code:

AD-1252 Thermal Dispersion Probe Airflow Measuring System Installation Instructions 1

preliminary - this information may change

Applications

The AD-1252 Thermal Dispersion Probe Airflow

Measuring System is an air-measurement device that

uses thermal dispersion technology to measure the

airflow velocity and temperature in duct and plenum

applications. Insertion probes are typically installed in

retrofit applications but may also be specified on new

construction projects.

The product may be used in rectangular, oval or round

applications when installed in accordance with this

installation manual. Use behind a rain hood, in front of

an outside air damper, return air duct, downstream of a

fan discharge or in the exhaust duct.

North American Emissions Compliance

United States

Canada

Installation

Mounting

The sensor density is based on extensive lab testing to

optimize the accuracy of the electronic controller.

When installing the thermal dispersion probe(s), use

the Square Duct Mounting and Round Duct Mounting

sections to determine the proper spacing between

each probe within the opening. Contact your local

Johnson Controls® representative if you have

questions regarding a particular application.

This equipment has been tested and found to

comply with the limits for a Class A digital device

pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection

against harmful interference when this equipment is

operated in a commercial environment. This

equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in

accordance with the instruction manual, may cause

harmful interference to radio communications.

Operation of this equipment in a residential area is

likely to cause harmful interference, in which case

the user will be required to correct the interference

at his/her own expense.

This Class (A) digital apparatus meets all the

requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique de la Classe (A) respecte

toutes les exigences du Règlement sur le matériel

brouilleur du Canada.

WARNING: Risk of Electric Shock

Disconnect power supply before making

electrical connections. Contact with

components carrying hazardous voltage can

cause electrical shock and may result in

severe personal injury or death.

IMPORTANT: Only a qualified service technician

should install this system. To avoid unsatisfactory

operation or damage to the product, strictly follow

the instructions provided and do not substitute parts.

Damage to the product resulting from not following

the instructions or using unauthorized parts may be

excluded from the manufacturer’s warranty

coverage.

AD-1252 Thermal Dispersion Probe Airflow Measuring

System

Installation Instructions Part No. 44-1122-2, Rev. -

Issued June 30, 2009

MPORTANT: Only a qualied service technician Ishould install this system. To avoid unsatisfactory operation

or damage to the product, strictly follow the instructions provided and do not substitute parts. Damage to the

product resulting from not following the instructions or using unauthorized parts may be excluded from the

manufacturer’s warranty coverage.

Confirm power requirements before wiring actuator. Ruskin is not responsible for any damage to, or failure of

the unit caused by incorrect field wiring.

IMPORTANT: In addition to these instructions, the installation contractor shall comply with all local and Interna-

tional codes and standards to ensure proper and safe installation.

Airflow-IQ Start-up & Commissioning Guide

4

Risk of Electric Shock.

Disconnect the power supply before making electrical connections. Contact with components carrying hazardous

voltage can cause electric shock and may result in severe personal injury or death.

Risque de décharge électrique.

Débrancher l'alimentation avant de réaliser tout branchement électrique. Tout contact avec des composants

conducteurs de tensions dangereuses risque d'entraîner une décharge électrique et de provoquer des blessures

graves, voire mortelles.

AD-1252 Thermal Dispersion Probe Airflow Measuring System Installation Instructions 1

preliminary - this information may change

Applications

The AD-1252 Thermal Dispersion Probe Airflow

Measuring System is an air-measurement device that

uses thermal dispersion technology to measure the

airflow velocity and temperature in duct and plenum

applications. Insertion probes are typically installed in

retrofit applications but may also be specified on new

construction projects.

The product may be used in rectangular, oval or round

applications when installed in accordance with this

installation manual. Use behind a rain hood, in front of

an outside air damper, return air duct, downstream of a

fan discharge or in the exhaust duct.

North American Emissions Compliance

United States

Canada

Installation

Mounting

The sensor density is based on extensive lab testing to

optimize the accuracy of the electronic controller.

When installing the thermal dispersion probe(s), use

the Square Duct Mounting and Round Duct Mounting

sections to determine the proper spacing between

each probe within the opening. Contact your local

Johnson Controls® representative if you have

questions regarding a particular application.

This equipment has been tested and found to

comply with the limits for a Class A digital device

pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection

against harmful interference when this equipment is

operated in a commercial environment. This

equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in

accordance with the instruction manual, may cause

harmful interference to radio communications.

Operation of this equipment in a residential area is

likely to cause harmful interference, in which case

the user will be required to correct the interference

at his/her own expense.

This Class (A) digital apparatus meets all the

requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique de la Classe (A) respecte

toutes les exigences du Règlement sur le matériel

brouilleur du Canada.

ARNING: Risk of Electric Shock

nnect power supply before making

ectrical connections. Contact with

nents carrying hazardous voltage can

electrical shock and may result in

severe personal injury or death.

IMPORTANT: Only a qualified service technician

should install this system. To avoid unsatisfactory

operation or damage to the product, strictly follow

the instructions provided and do not substitute parts.

Damage to the product resulting from not following

the instructions or using unauthorized parts may be

excluded from the manufacturer’s warranty

coverage.

AD-1252 Thermal Dispersion Probe Airflow Measuring

System

Installation Instructions Part No. 44-1122-2, Rev. -

Issued June 30, 2009

Software Configuration Information for Commissioning:

After the installation described in this document is complete, please refer to the TDP05K Technical Bulletin

for information regarding conguration options.

The Technical Bulletin document can be viewed or downloaded at this location:

http://www.ruskin.com/catalog/servele/id/6767.

The Technical Bulletin document can also be accessed via this QR Code:

AD-1252 Thermal Dispersion Probe Airflow Measuring System Installation Instructions 1

preliminary - this information may change

Applications

The AD-1252 Thermal Dispersion Probe Airflow

Measuring System is an air-measurement device that

uses thermal dispersion technology to measure the

airflow velocity and temperature in duct and plenum

applications. Insertion probes are typically installed in

retrofit applications but may also be specified on new

construction projects.

The product may be used in rectangular, oval or round

applications when installed in accordance with this

installation manual. Use behind a rain hood, in front of

an outside air damper, return air duct, downstream of a

fan discharge or in the exhaust duct.

North American Emissions Compliance

United States

Canada

Installation

Mounting

The sensor density is based on extensive lab testing to

optimize the accuracy of the electronic controller.

When installing the thermal dispersion probe(s), use

the Square Duct Mounting and Round Duct Mounting

sections to determine the proper spacing between

each probe within the opening. Contact your local

Johnson Controls® representative if you have

questions regarding a particular application.

This equipment has been tested and found to

comply with the limits for a Class A digital device

pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection

against harmful interference when this equipment is

operated in a commercial environment. This

equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in

accordance with the instruction manual, may cause

harmful interference to radio communications.

Operation of this equipment in a residential area is

likely to cause harmful interference, in which case

the user will be required to correct the interference

at his/her own expense.

This Class (A) digital apparatus meets all the

requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique de la Classe (A) respecte

toutes les exigences du Règlement sur le matériel

brouilleur du Canada.

WARNING: Risk of Electric Shock

Disconnect power supply before making

electrical connections. Contact with

components carrying hazardous voltage can

cause electrical shock and may result in

severe personal injury or death.

IMPORTANT: Only a qualified service technician

should install this system. To avoid unsatisfactory

operation or damage to the product, strictly follow

the instructions provided and do not substitute parts.

Damage to the product resulting from not following

the instructions or using unauthorized parts may be

excluded from the manufacturer’s warranty

coverage.

AD-1252 Thermal Dispersion Probe Airflow Measuring

System

Installation Instructions Part No. 44-1122-2, Rev. -

Issued June 30, 2009

MPORTANT: Only a qualied service technician Ishould install this system. To avoid unsatisfactory operation

or damage to the product, strictly follow the instructions provided and do not substitute parts. Damage to the

product resulting from not following the instructions or using unauthorized parts may be excluded from the

manufacturer’s warranty coverage.

Confirm power requirements before wiring actuator. Ruskin is not responsible for any damage to, or failure of

the unit caused by incorrect field wiring.

IMPORTANT: In addition to these instructions, the installation contractor shall comply with all local and Interna-

tional codes and standards to ensure proper and safe installation.

Airflow-IQ Start-up & Commissioning Guide

4

Risk of Electric Shock.

Disconnect the power supply before making electrical connections. Contact with components carrying hazardous

voltage can cause electric shock and may result in severe personal injury or death.

Risque de décharge électrique.

Débrancher l'alimentation avant de réaliser tout branchement électrique. Tout contact avec des composants

conducteurs de tensions dangereuses risque d'entraîner une décharge électrique et de provoquer des blessures

graves, voire mortelles.

Risk of Electric Shock.

Disconnect the power supply before making electrical connections. Contact with components carrying hazardous

voltage can cause electric shock and may result in severe personal injury or death.

Risque de décharge électrique.

Débrancher l’alimentation avant de réaliser tout branchement électrique. Tout contact avec des composants

conducteurs de tensions dangereuses risque d’entraîner une décharge électrique et de provoquer des blessures

graves, voire mortelles.