Locating the Fan Inlet Sensors on

centrifugal Forward Curve Fans

Mounting the Inlet Sensors

Inspect the fan inlet opening to ensure no

obstructions or irregularities interfere with installation

of the sensors. Install the two fan inlet sensors

opposite one another within the fan inlet bell. Place

the sensor housing at or near the highest restriction

point of the fan inlet as possible. Be careful to not

bend or touch the thermistors while installing.

Sensors should be placed at the 12:00 o’clock and

6:00 o’clock positions, directly opposite one another

in a similar fashion for fans with the air exiting on the

right or left of the housing. See Figure 1.

Sensors should be placed at the 3:00 o’clock and

9:00 o’clock positions, directly opposite one another

for fans with the air exiting on the top or bottom of

the fan housing. See Figure 2.

On dual inlet fans, install two sensor circuits within

each fan inlet bell. Place the sensor at or near the

highest restriction point of each inlet as possible.

Use the supplied pan head, self-drilling fasteners

(included in parts bag) to fasten the fan inlet sensor

to the inlet bell. Use nylon cable clamps (included in

parts bag) to secure RJ45 cable to the inlet bell.

If the fan has a shallow inlet bell, use a box knife or

other utility knife to remove the Air Leaving Wedge,

leaving the primary sensor housing (containing the

sensor circuit) and the Air Entering Wedge. Use the

mounting hole on the Primary Sensor Housing if you

remove the Air Leaving Wedge.

Locating the Fan Inlet Sensors on Forward

Curve Fans

Inspect the fan inlet opening to ensure no

obstructions or irregularities interfere with installation

of the sensors. Install the two fan inlet sensors

opposite one another within the fan inlet bell. Place

the sensor housing at or near the highest restriction

point of the fan inlet as possible.

Sensors should be placed at the 12:00 o'clock and

6:00 o'clock positions, directly opposite one another

in a similar fashion for fans with the air exiting on the

right or left of the housing. See Figure 1.

Sensors should be placed at the 3:00 o'clock and

9:00 o'clock positions, directly opposite one another

for fans with the air exiting on the top or bottom of the

housing. See Figure 2.

On dual inlet fans, install two sensor circuits within

each fan inlet bell. Place the sensor housing at or

near the highest restriction point of each inlet as

possible.

Figure 1: Sensor Mounting

Figure 2: Sensor Mounting

Mounting the Fan Inlet Sensors

Use the supplied pan head, self-drilling fasteners

(included in parts bag) to fasten the fan inlet sensor to

the inlet bell.

If the fan has a shallow inlet bell, use a box knife or

other utility knife to remove the Air Leaving Wedge,

leaving the primary sensor housing (containing the

sensor circuit) and the Air Entering Wedge. Use the

mounting hole on the Primary Sensor Housing if you

remove the Air Leaving Wedge.

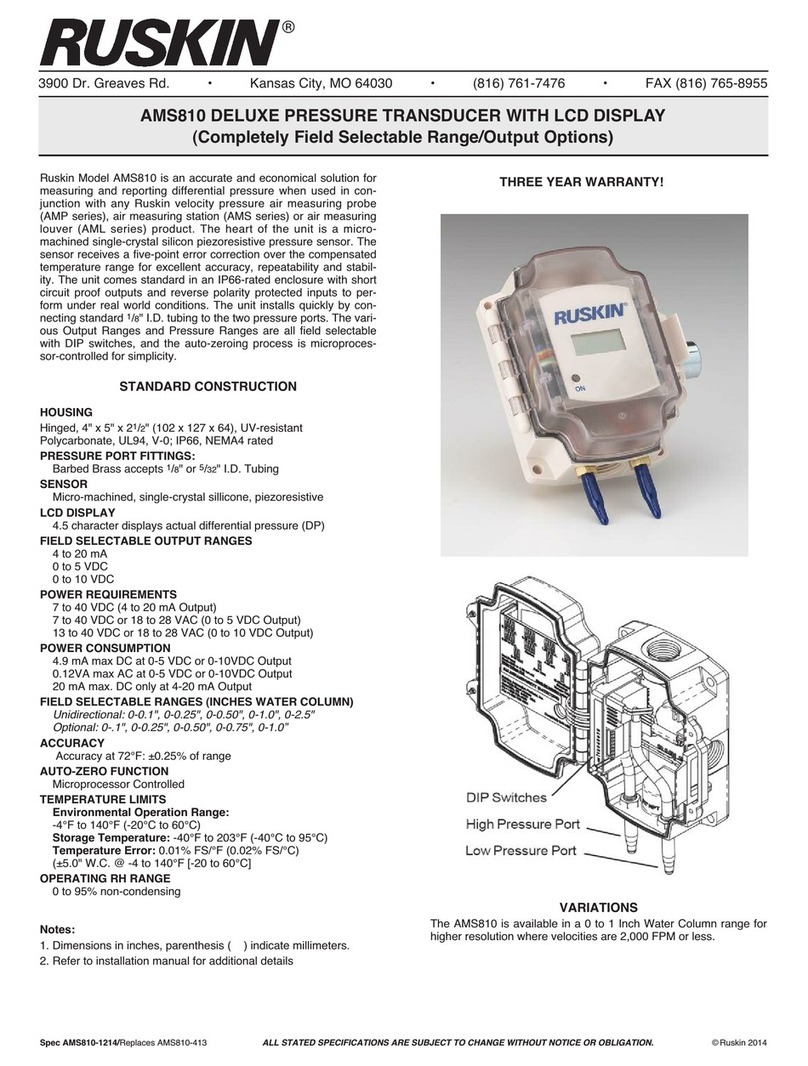

Figure 3: Fan Inlet Sensor

Note: Ensure that the airflow arrow is pointed in the

correct direction.

Figure 4: Fan Inlet Sensor Dimensions, in. (mm)

RUSKIN EFAMS Thermal Dispersion Airflow Measuring System Installation Instructions

Figure 1: Sensor Mounting

Figure 2: Sensor Mounting

RUSKIN EFAMS THERMAL DISPERSION AIRFLOW MEASURING SYSTEM INSTALLATION INSTRUCTIONS

4

Locating the Fan Inlet Sensors on Forward

Curve Fans

Inspect the fan inlet opening to ensure no

obstructions or irregularities interfere with installation

of the sensors. Install the two fan inlet sensors

opposite one another within the fan inlet bell. Place

the sensor housing at or near the highest restriction

point of the fan inlet as possible.

Sensors should be placed at the 12:00 o'clock and

6:00 o'clock positions, directly opposite one another

in a similar fashion for fans with the air exiting on the

right or left of the housing. See Figure 1.

Sensors should be placed at the 3:00 o'clock and

9:00 o'clock positions, directly opposite one another

for fans with the air exiting on the top or bottom of the

housing. See Figure 2.

On dual inlet fans, install two sensor circuits within

each fan inlet bell. Place the sensor housing at or

near the highest restriction point of each inlet as

possible.

Figure 1: Sensor Mounting

Figure 2: Sensor Mounting

Mounting the Fan Inlet Sensors

Use the supplied pan head, self-drilling fasteners

(included in parts bag) to fasten the fan inlet sensor to

the inlet bell.

If the fan has a shallow inlet bell, use a box knife or

other utility knife to remove the Air Leaving Wedge,

leaving the primary sensor housing (containing the

sensor circuit) and the Air Entering Wedge. Use the

mounting hole on the Primary Sensor Housing if you

remove the Air Leaving Wedge.

Figure 3: Fan Inlet Sensor

Note: Ensure that the airflow arrow is pointed in the

correct direction.

Figure 4: Fan Inlet Sensor Dimensions, in. (mm)

RUSKIN EFAMS Thermal Dispersion Airflow Measuring System Installation Instructions

Locating the Fan Inlet Sensors on Forward

Curve Fans

Inspect the fan inlet opening to ensure no

obstructions or irregularities interfere with installation

of the sensors. Install the two fan inlet sensors

opposite one another within the fan inlet bell. Place

the sensor housing at or near the highest restriction

point of the fan inlet as possible.

Sensors should be placed at the 12:00 o'clock and

6:00 o'clock positions, directly opposite one another

in a similar fashion for fans with the air exiting on the

right or left of the housing. See Figure 1.

Sensors should be placed at the 3:00 o'clock and

9:00 o'clock positions, directly opposite one another

for fans with the air exiting on the top or bottom of the

housing. See Figure 2.

On dual inlet fans, install two sensor circuits within

each fan inlet bell. Place the sensor housing at or

near the highest restriction point of each inlet as

possible.

Figure 1: Sensor Mounting

Figure 2: Sensor Mounting

Mounting the Fan Inlet Sensors

Use the supplied pan head, self-drilling fasteners

(included in parts bag) to fasten the fan inlet sensor to

the inlet bell.

If the fan has a shallow inlet bell, use a box knife or

other utility knife to remove the Air Leaving Wedge,

leaving the primary sensor housing (containing the

sensor circuit) and the Air Entering Wedge. Use the

mounting hole on the Primary Sensor Housing if you

remove the Air Leaving Wedge.

Figure 3: Fan Inlet Sensor

Note: Ensure that the airflow arrow is pointed in the

correct direction.

Figure 4: Fan Inlet Sensor Dimensions, in. (mm)

RUSKIN EFAMS Thermal Dispersion Airflow Measuring System Installation Instructions

Figure 3: Fan Inlet Sensor

Note: Ensure that the airow arrow is pointed in the

correct direction.

Figure 4: Fan Inlet Sensor Dimensions, in. (mm)

120

(3048)

13/8(35)

1 (25)

31/8(79)

1/2(13)

Airflow

Primary

Sensor

Housing

Air

Leaving

Wedge

Air

Entering

Wedge

Ambient

Thermistor

Heated

Thermistor

Remove piece for shallow

inlet bell installations