Product Application............................................................................................................................................................................2

Key Features .....................................................................................................................................................................................2

Key Benets .......................................................................................................................................................................................2

Construction Details...........................................................................................................................................................................3

Installation ..........................................................................................................................................................................................3

Installations Air Measurement Station Placements............................................................................................................................4

Duct Diameter Equivalents Chart .......................................................................................................................................................5

Sequence of Operation ......................................................................................................................................................................6

Standard RU-274-R2-VDC Transducer Wiring Details ......................................................................................................................7

Specications.....................................................................................................................................................................................8

Maintenance.......................................................................................................................................................................................8

TABLE OF CONTENTS

! WARNING

READ THESE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING TO INSTALL, OPERATE OR SERVICE

THIS DEVICE.

THIS ACCESSORY IS TO BE INSTALLED BY A QUALIFIED SERVICE TECHNICIAN. TO AVOID UNSATISFAC-

TORY OPERATION OR DAMAGE TO THE PRODUCT AND POSSIBLE UNSAFE CONDITIONS, INCLUDING

ELECTRICAL SHOCK AND FIRE, THE INSTALLATION INSTRUCTIONS PROVIDED WITH THIS ACCESSORY

MUST BE STRICTLY FOLLOWED AND THE PARTS SUPPLIED USED WITHOUT SUBSTITUTION. DAMAGE

TO THE PRODUCT RESULTING FROM NOT FOLLOWING THE INSTRUCTIONS OR USING UNAUTHORIZED

PARTS MAY BE EXCLUDED FROM THE MANUFACTURER’S WARRANTY COVERAGE.

! WARNING

DISCONNECT ELECTRICAL POWER PRIOR TO SERVICING THIS UNIT. FAILURE TO DO SO CAN RESULT IN

ELECTRICAL SHOCK RESULTING IN PERSONAL INJURY OR DEATH.

2

Product Application

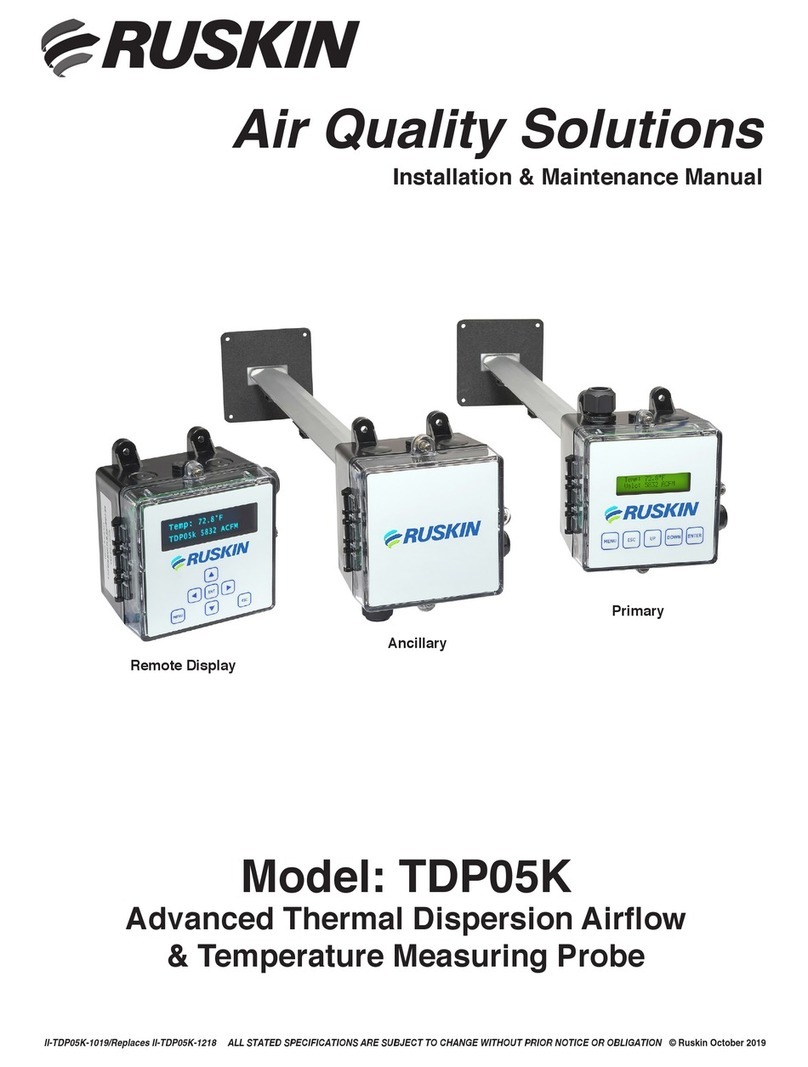

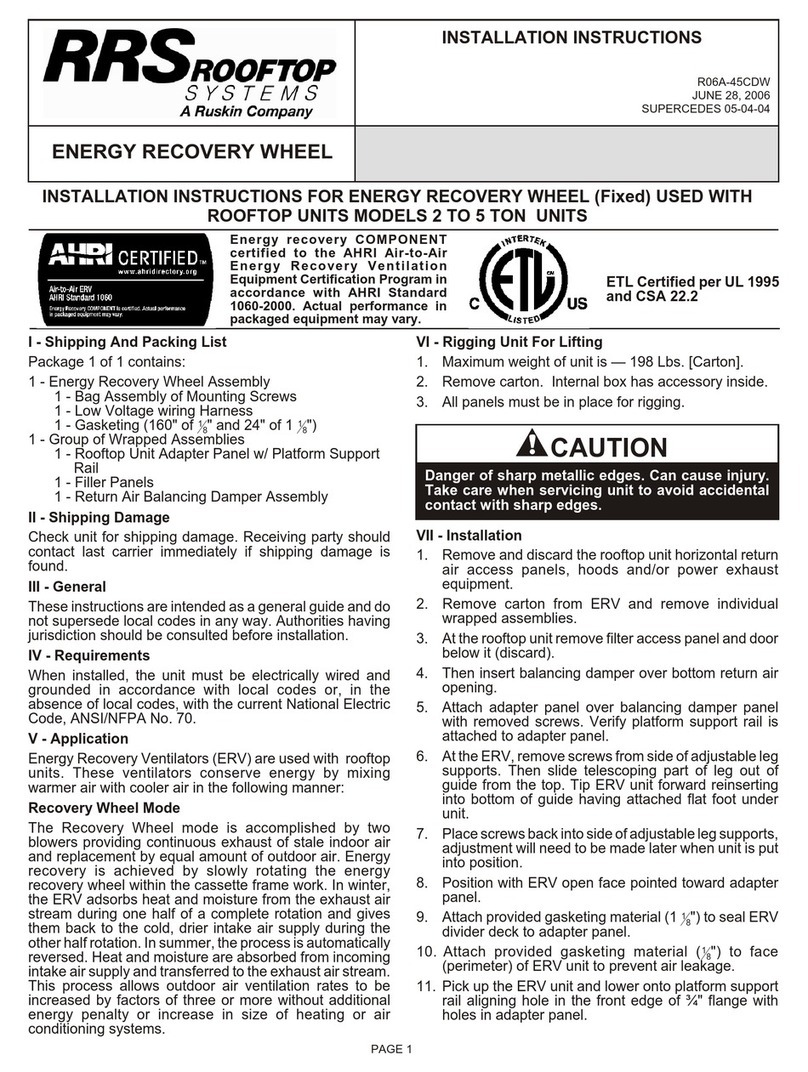

The Air Measuring Station (AMS) is designed to be used in any application that requires accurate airow measurement

at velocities between 300 and 5,000 feet per minute (1.5 and 25 m/s). Unit may be installed in the duct or in an air

handling unit and can be used to measure outside air, return air, discharge air or exhaust air ows into or out of a

building or air handling unit.

Key Features

• Licensed to bear the AMCA Certied Ratings Seal for Airow Measurement Station Performance

• Combines Ruskin’s exclusive anodized aluminum step sensor with a 3” (76mm) deep 3000 series aluminum

honeycomb air straightener for accurate measurement to maximize performance and oer repeatable and

accurate results.

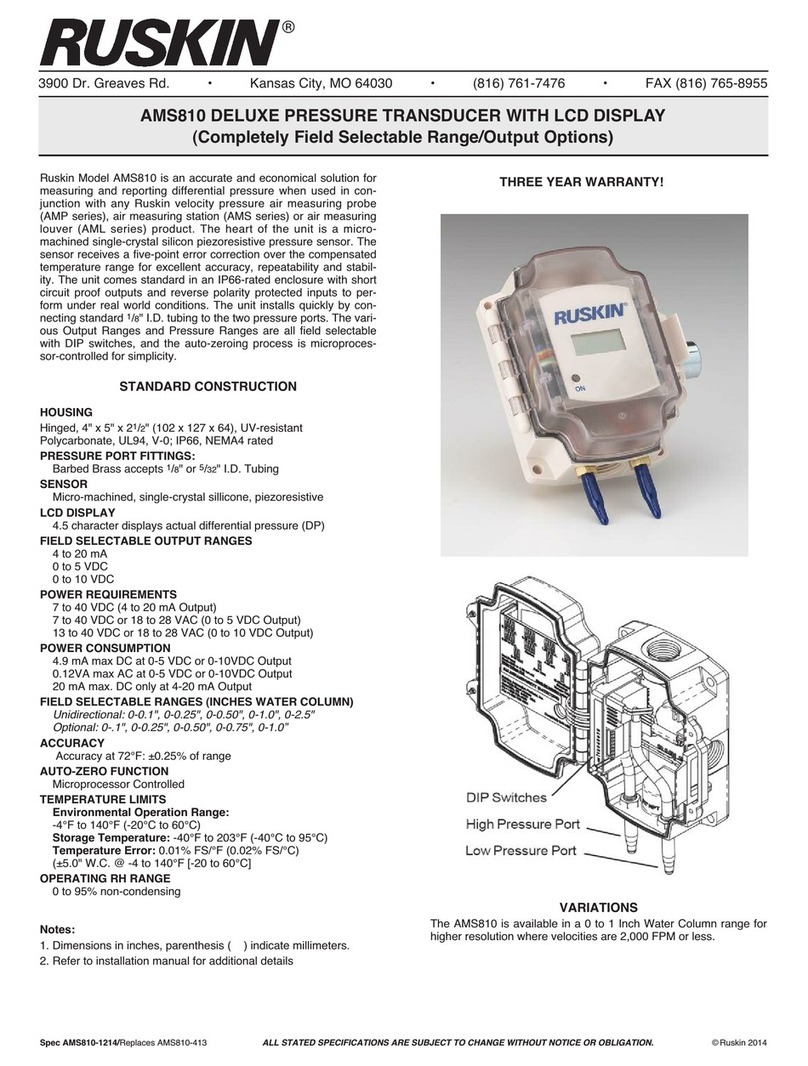

• Velocity Pressure with Dead-Head transducer.

• Field selectable pressure ranges for greatest measurement resolution.

Key Benets

• Contributes to earning required Indoor Environmental Quality (EQ) and Energy and Atmosphere (EA) LEED

prerequisites.

• Save energy dollars by measuring the minimum ventilation airow.

• Meet International Building Code (IBC) and International Energy Conservation Code (IECC) requirements.

• Maintain proper ventilation to dissipate dangerous indoor contaminants such as mold spores, bacteria and

chemicals.

• Create a healthy indoor environment to reduce absenteeism, increase productivity, improve comfort and

reduce the risk of litigation