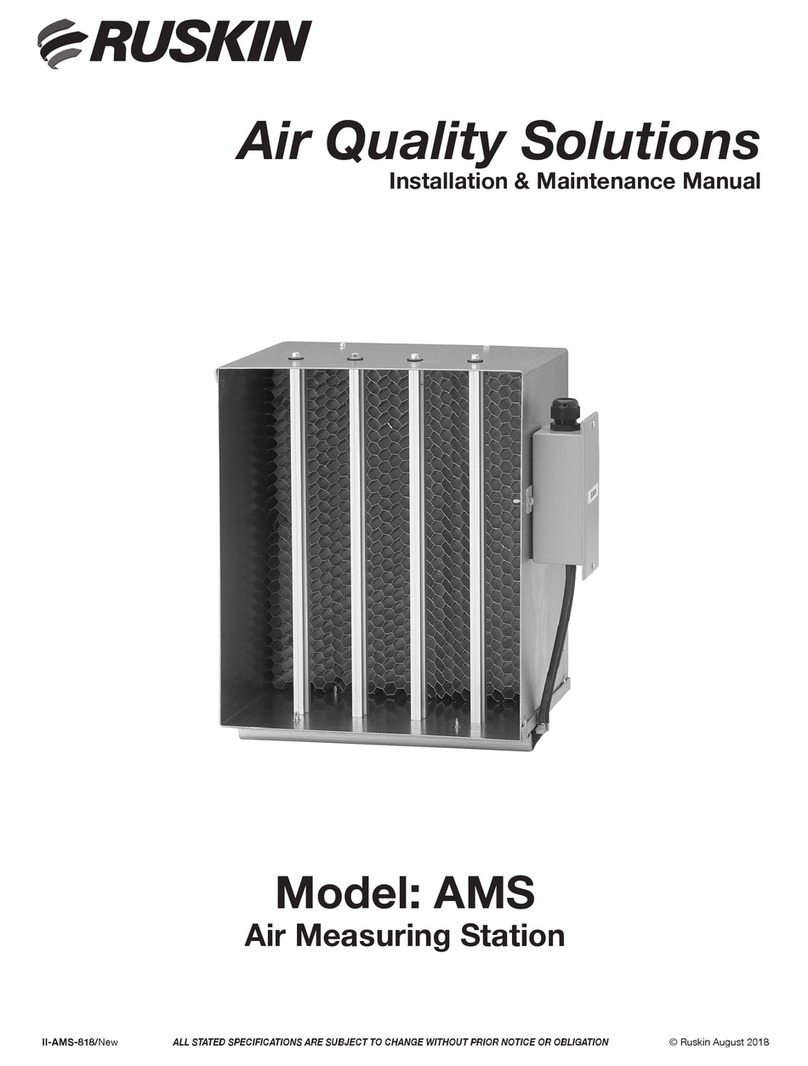

#()"")!$#(30"'4="0,>@=492'?,?4:9B4?39?02=,7/,8;0=,9/:;?4:9,7/424?,7.:9?=:770=;,9078,D>34;49>0;,=,?0.:9?,490=>%70,>0A0=41D?3,?D:@3,A0=0.04A0/0A0=D?34929:?0/:9?30;,.6492>74;;=4:=?:;=:.00/492B4?3?3049>?,77,?4:9&08:A0?30"'1=:84?>>34;;492.:9?,490=,9/49>;0.?1:=/,8,20=@>?:=.:==:>4:9,=08@>?-0?,609493,9/7492?30@94?7B,D>3,9/70?30"'-D4?>1=,80:9:?741?4?-D?30-7,/07496,20,C708:?:=:=5,.6>3,1?:9:?/=:;/=,2>?0;:9:=,;;7D0C.0>>4A0-09/492?B4>?492:==,.64927:,/>?:?30"'';0.4,7.,=0>3:@7/-0@>0/?:;=:?0.??303:90D.:8->?=,423?090=9>;0.??30/@.?B:=6,9/:=:;09492B30=0?30"',>>08-7DB477-049>?,770/1:=,9D:->?=@.?4:9:=4==02@7,=4?40>?3,?8423?49?0=10=0B4?3-7,/0:=7496,20=:?,?4:9:=:;?4:9,7,.?@,?:=8:@9?49214?4>?:-049>?,770/49/@.?B:=6?30/@.?B:=6>3:@7/-0>@;;:=?0/,??30,=0,:1?30"'?:;=0A09?>,22492/@0?:?30@94?>B0423?(30"'8@>?-049>?,770/B4?3?301=,80><@,=0,9/B4?3:@??B4>?492:=-09/492(30@94?8@>?-049>?,770/B4?34?>-7,/0,C4>3:=4E:9?,7(30/,8;0=-7,/0>,C70>,9/7496,208@>?-0,-70?::;0=,?0B4?3:@?-09/492(30-0>?7:.,?4:91:=?300C?09/0/>3,1?:=5,.6>3,1?8@>?-0/0?0=8490/-01:=049>?,77492?30/,8;0=(30/,8;0=8,D-0=:?,?0//02=00>?:20??300C?09/0/>3,1?:9?30.:==0.?>4/0:1?30/@.?B:=61?0=?30/,8;0=4>49>?,770/?30>3,1?7:.,?4:9.,99:?-0.3,920/B4?3:@?=08:A492?30/,8;0=(305,.6>3,1?4149>?,770/B477,7B,D>-049?3070,A492,4=>?=0,8(30"'3,>,>;0.4140/4970?,9/:@?70?(30:@?>4/0,4=:=:?30=.:9?=:770/,4=>?=0,809?0=>?30@94??3=:@23?30,4=>?=,423?09492>0.?4:9,9/0C4?>1=:8?30/,8;0=>4/0)>0,;;=:;=4,?0>348>-0?B009?30/,8;0=1=,80,9//@.?:;09492?:;=0A09?/4>?:=?4:9:1?301=,80-D1,>?090=>3:7/4924?49;7,.01.=0,?492,8@7?4>0.?4:9,>>08-7D-0>@=0?3,?,77?30>0.?4:9>,=01,>?090/?:20?30=:9-:?3>4/0>1?30,.?@,?:=7496,20:=>3,1?492;=0>09?,;=:-7081:=49>?,77,?4:9;70,>0.:9>@7?D:@=7:.,7&@>649=0;=0>09?,?4A0:=?30&@>6491,.?:=D(30"'>3:@7/-0.D.70?0>?0/,1?0=49>?,77,?4:9?:,>>@=0;=:;0=:;0=,?4:91?0=49>?,77492?30,>>08-7D49?30/@.?B:=6:=8:@9?4923:70.,@76,=:@9/?30/,8;0=1=,80?:49>@=0?3,??30=04>9:70,6,20:=-D;,>>,4=,=:@9/?30,4=80,>@=492>?,?4:9(30:;?4:9,7"':9?=:7@94?4>1,.?:=D.,74-=,?0/,9/?0>?0/49:=/0=?:;0=1:=8.:==0.?7D494?>5:->;0.414.,;;74.,?4:9(30424?,7:9?=:7@94?4>?D;4.,77D>34;;0/7::>049,#"070.?=4.,709.7:>@=0,9/8@>?-049>?,770/B4?349100?:1?30"'49,909A4=:9809?,77D.:9?=:770/>;,.0B4=492>.308,?4.7,-074>7:.,?0/:9?30.:A0=;7,?01:=1@?@=0=010=09.0,9/49?34>/:.@809?(3009.7:>@=08@>?-0>0.@=07D,??,.30/?:,17,?>:74/>@=1,.0>@.3,>,B,77:=,4=3,9/7492@94?.,>492&010=?:B4=492>.308,?4.,9/.:9?=:7>>0.?4:9:1?34>/:.@809?1:=90.0>>,=D1407/;:B0=.:990.?4:9>&010=?:;,201:=4/0,7,;;74.,?4:9>;0.414.,4=80,>@=492;=:/@.?;7,.0809?:;?4:9>:9>@7?D:@=7:.,7=0;=0>09?,?4A0B4?3<@0>?4:9>,-:@?;7,.0809?