Safety

2

or remove the battery pack, if detachable, from

the power tool before making any adjustments,

changing accessories, or storing power tools. Such

preventive safety measures reduce the risk of starting

the power tool accidentally.

■Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained

users.

■Maintain power tools and accessories. Check for

misalignment or binding of moving parts, breakage

of parts and any other condition that may affect the

power tool’s operation. If damaged, have the power

tool repaired before use. Many accidents are caused

by poorly maintained power tools.

■Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

■Use the power tool, accessories and tool bits etc.

in accordance with these instructions, taking into

account the working conditions and the work to

be performed. Use of the power tool for operations

different from those intended could result in a

hazardous situation.

■Keep handles and grasping surfaces dry, clean

and free from oil and grease. Slippery handles and

grasping surfaces do not allow for safe handling and

control of the tool in unexpected situations.

SERVICE

■Have your power tool serviced by a qualified repair

person using only identical replacement parts.

This will ensure that the safety of the power tool is

maintained.

PLANER SAFETY WARNINGS

■Wait for the cutter to stop before setting the tool

down. An exposed rotating cutter may engage the

surface, leading to possible loss of control and serious

injury.

■Hold the power tool by insulated gripping surfaces,

because the cutter may contact its own cord.

Cutting a “live” wire may make exposed metal parts

of the power tool “live” and could give the operator an

electric shock.

■Use clamps or another practical way to secure and

support the workpiece to a stable platform. Holding

the workpiece by your hand or against the body leaves

it unstable and may lead to loss of control.

ADDITIONAL SAFETY RULES

■The dust produced when using this tool may be harmful

to health. Do not inhale the dust. Use a dust absorption

system and wear a suitable dust protection mask.

Remove deposited dust thoroughly, e.g., with a vacuum

cleaner.

■Do not remove splinters or saw dust while tool is

running.

■Only plane with sharp blades, avoid metals (nails,

screws). Check the workpiece before planing.

■Do not reach into the danger area of the tool when

plugged in.

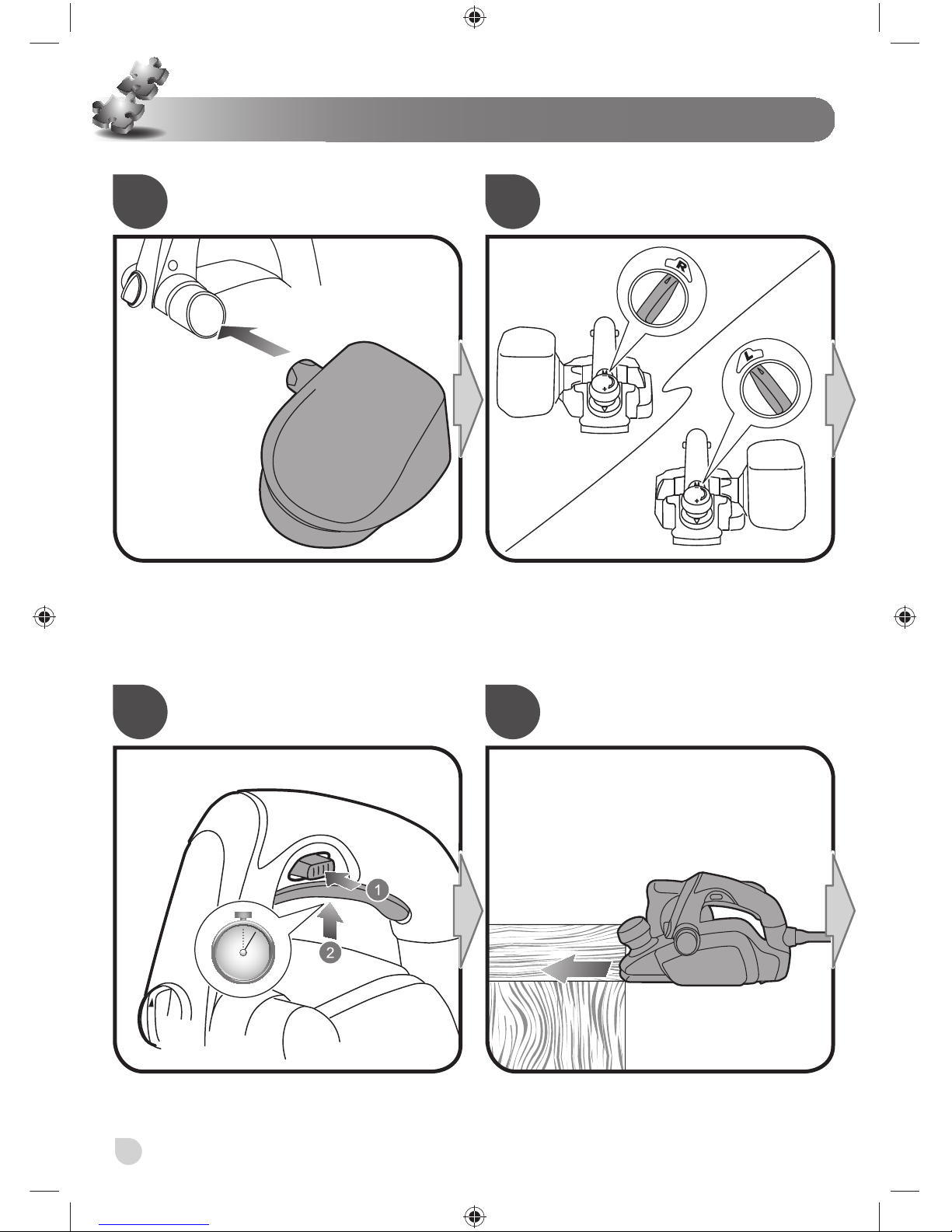

■Place the front plate of the machine on to the workpiece

and switch on, before the planer blade touches the

workpiece and then guide evenly over the workpiece.

■The v-shape notch in the front of the supporting plate

ensures safe chamfering of edges.

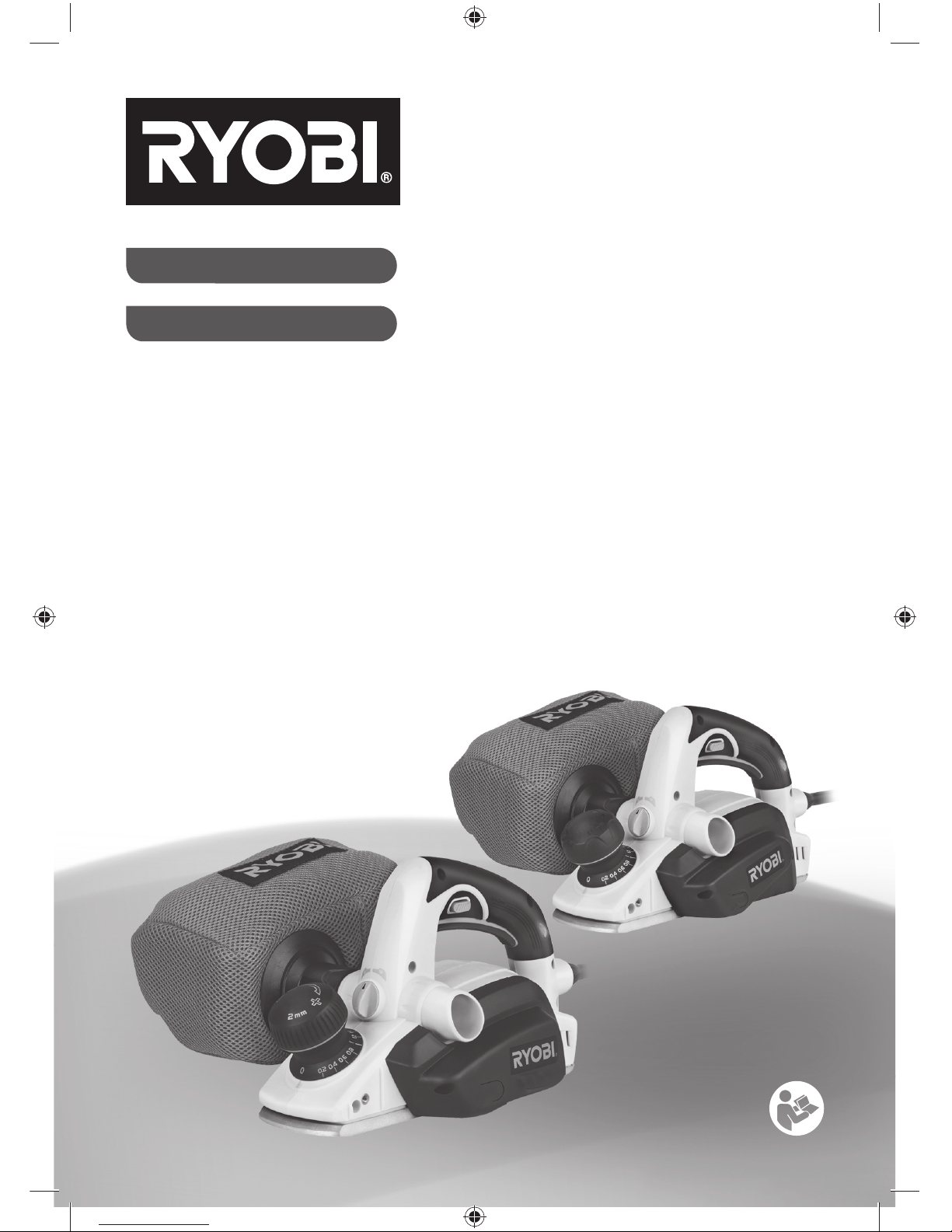

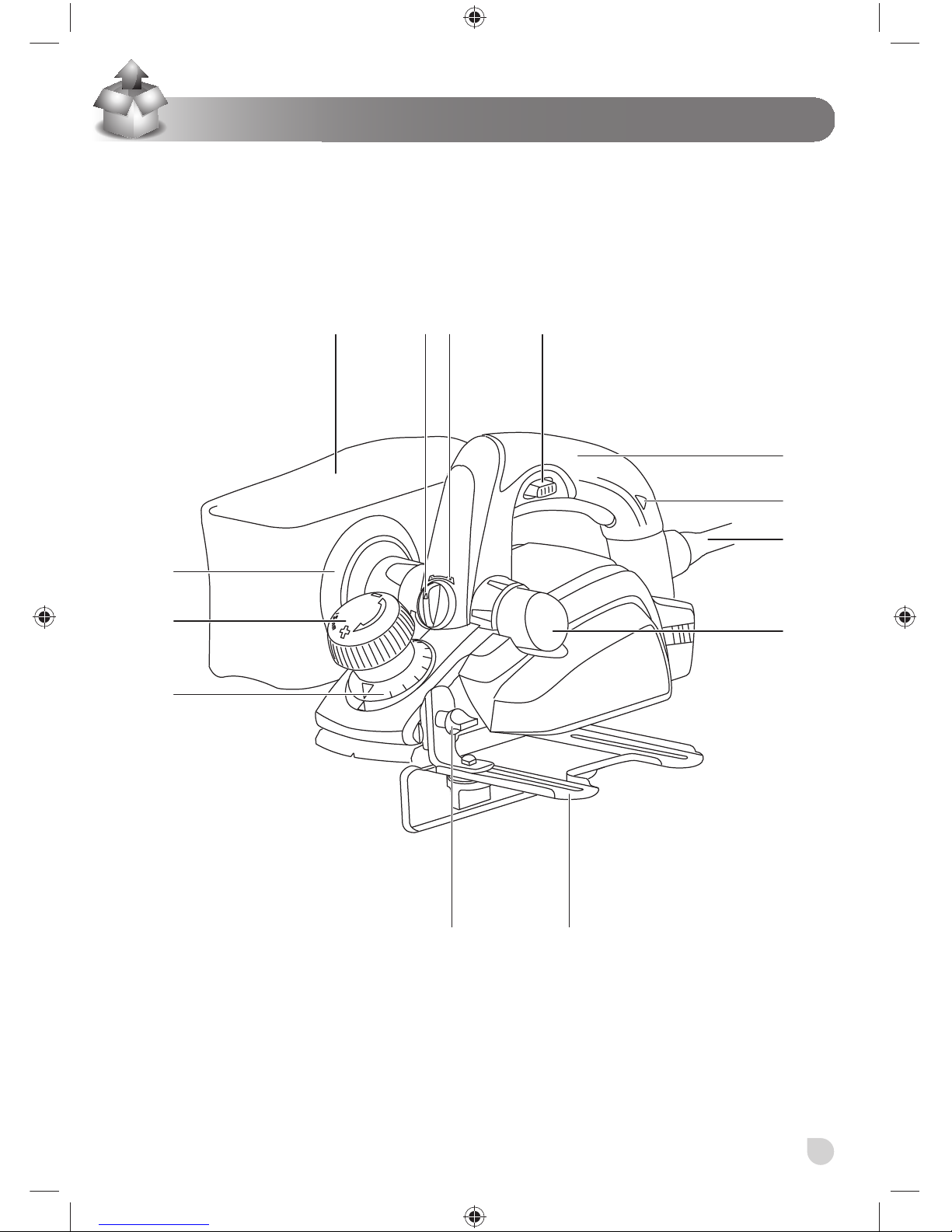

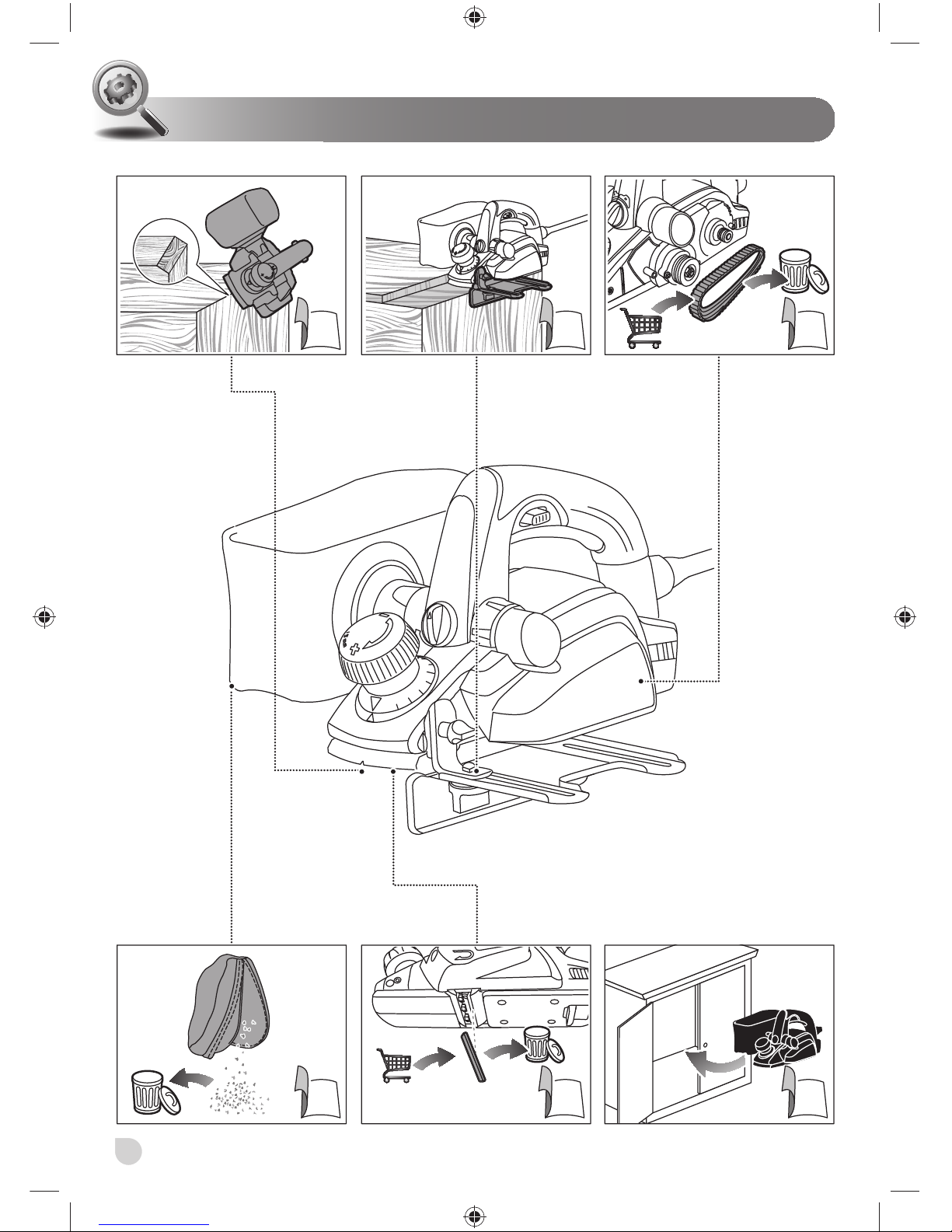

KNOW YOUR PRODUCT

See page 5.

1. Lock-off button

2. Dust flow direction mark

3. Dust flow direction knob

4. Dust bag

5. Dust bag adaptor

6. Depth adjustment knob

7. Depth scale

8. Live tool indicator

9. Power cable

10. Dust outlet

11. Side fence knob

12. Side fence

13. Handle, insulated gripping surface

MAINTENANCE

■If the power supply cord is damaged, it must be replaced

only by the manufacturer or by an authorised service

centre to avoid risk. Contact authorised service centre.

■If the replacement of the supply cord is necessary, this

has to be done by the manufacturer or his agent in

order to avoid a safety hazard.

■The tool should never be connected to a power supply

when you are assembling parts, making adjustments,

cleaning, performing maintenance, or when the tool is

not in use. Disconnecting the tool will prevent accidental

starting that could cause serious injury.

■When servicing use only identical RYOBI replacement

parts. Use of any other parts may create a hazard or

cause product damage.

■Replace worn blades with new ones.

■Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to various types of commercial

solvents and may be damaged by their use. Use clean

cloths to remove dirt, carbon dust, etc.

■Do not at any time let brake fluids, gasoline, petroleum-

based products, penetrating oils come in contact with

plastic parts. They contain chemicals that can damage,

weaken or destroy plastic.