Page 3

RULES FOR SAFE OPERATION (Continued)

19. REMOVE ADJUSTING KEYS AND

WRENCHES. Form habit of checking to see

thatkeysandadjustingwrenchesareremoved

from tool before turning it on.

20. AVOIDACCIDENTALSTARTING. Don'tcarry

plugged-in tools with finger on switch. Be sure

switch is off when plugging in.

21. MAKESUREYOUREXTENSIONCORDISIN

GOODCONDITION.Whenusinganextension

cord,besureto useoneheavyenoughto carry

the current your product will draw. An under-

sized cord will cause a drop in line voltage

resulting in loss of power and overheating. A

wiregagesize(A.W.G.) ofatleast16is recom-

mended for an extension cord 100 feet or less

in length. A cord exceeding 100 feet is not

recommended.Ifindoubt,usethenextheavier

gage.Thesmallerthegagenumber,theheavier

the cord.

22 OUTDOORUSEEXTENSIONCORDS. When

toolisusedoutdoors, use onlyextensioncords

suitable for use outdoors. Outdoor approved

cords are marked with the suffix W-A, for ex-

ample - SJTW-A or SJOW-A.

23. NEVERUSETHISORANYPOWERSANDER

FOR WET SANDING OR LIQUID POLISH-

ING. Failure to comply can result in electrical

shock causing serious injury or worse.

24. KEEPHANDSAWAYFROMSANDINGAREA.

25. NEVER USE IN AN EXPLOSIVE ATMO-

SPHERE. Normal sparking of the motor could

ignite fumes.

26. INSPECTTOOLCORDSPERIODICALLYand

if damaged, have repaired by an authorized

service center. Stay constantly aware of cord

location.

27. INSPECT EXTENSION CORDS PERIODI-

CALLY and replace if damaged.

28. KEEP HANDLES DRY, CLEAN, AND FREE

FROMOILANDGREASE. Alwaysuseaclean

cloth when cleaning. Never use brake fluids,

gasoline,petroleum-basedproductsorsolvents

to clean your tool.

29. STAY ALERT. Watch what you are doing and

use common sense. Do not operate tool when

you are tired. Do not rush.

30. CHECK DAMAGED PARTS. Before further

use of the tool, a guard or other part that is

damagedshouldbecarefullycheckedtodeter-

minethatitwilloperateproperlyandperformits

intendedfunction.Checkforalignmentofmov-

ing parts, binding of moving parts, breakage of

parts, mounting, and any other conditions that

may affect its operation. A guard or other part

thatisdamagedshould be properly repaired or

replaced by an authorized service center.

31. DO NOT USE TOOL IF SWITCH DOES NOT

TURNITONANDOFF.Havedefectiveswitches

replaced by an authorized service center.

32. Inspect for and remove all nails from lumber

before sanding.

33. DRUGS, ALCOHOL, MEDICATION. Do not

operatetoolwhileunder the influenceofdrugs,

alcohol, or any medication.

34. When servicing use only identical Ryobi

replacement parts.

35. POLARIZED PLUGS. To reduce the risk of

electric shock, this equipment has a polarized

plug (one blade is wider than the other). This

plug will fit in a polarized outlet only one way. If

the plug does not fit fully in the outlet, reverse

theplug. Ifitstilldoesnotfit,contactaqualified

electrician to install the proper outlet. Do not

change the plug in any way.

36. SAVETHESEINSTRUCTIONS. Refertothem

frequently and use them to instruct others who

mayusethistool. Ifyouloansomeonethistool,

loan them these instructions also.

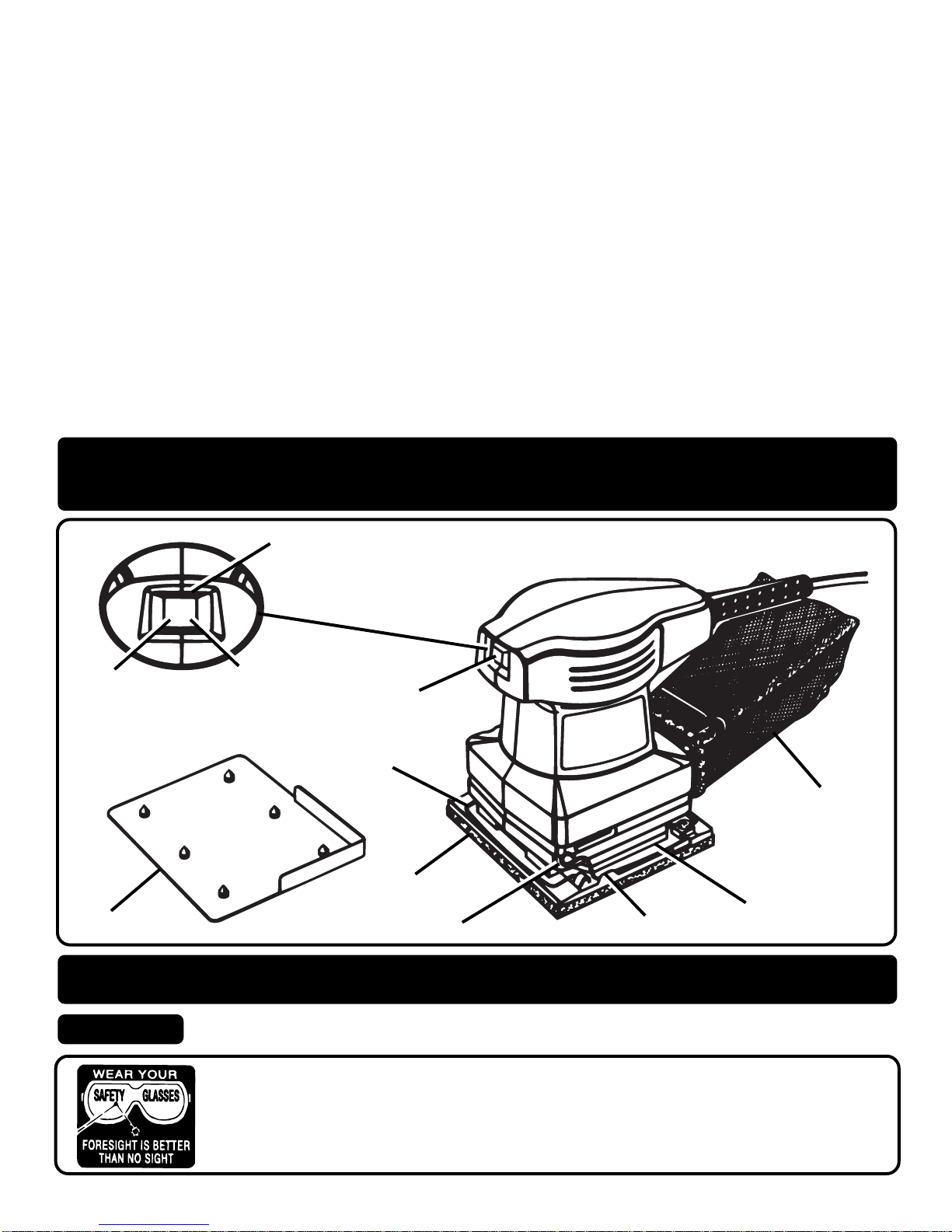

WARNING:

Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities

contains chemicals known to cause cancer, birth

defects or other reproductive harm. Some ex-

amples of these chemicals are:

•lead from lead-based paints,

•crystalline silica from bricks and cement and

other masonry products, and

•arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures varies, depend-

ing on how often you do this type of work. To re-

duce your exposure to these chemicals: work in

a well ventilated area, and work with approved

safety equipment, such as those dust masks that

are specially designed to filter out microscopic

particles.