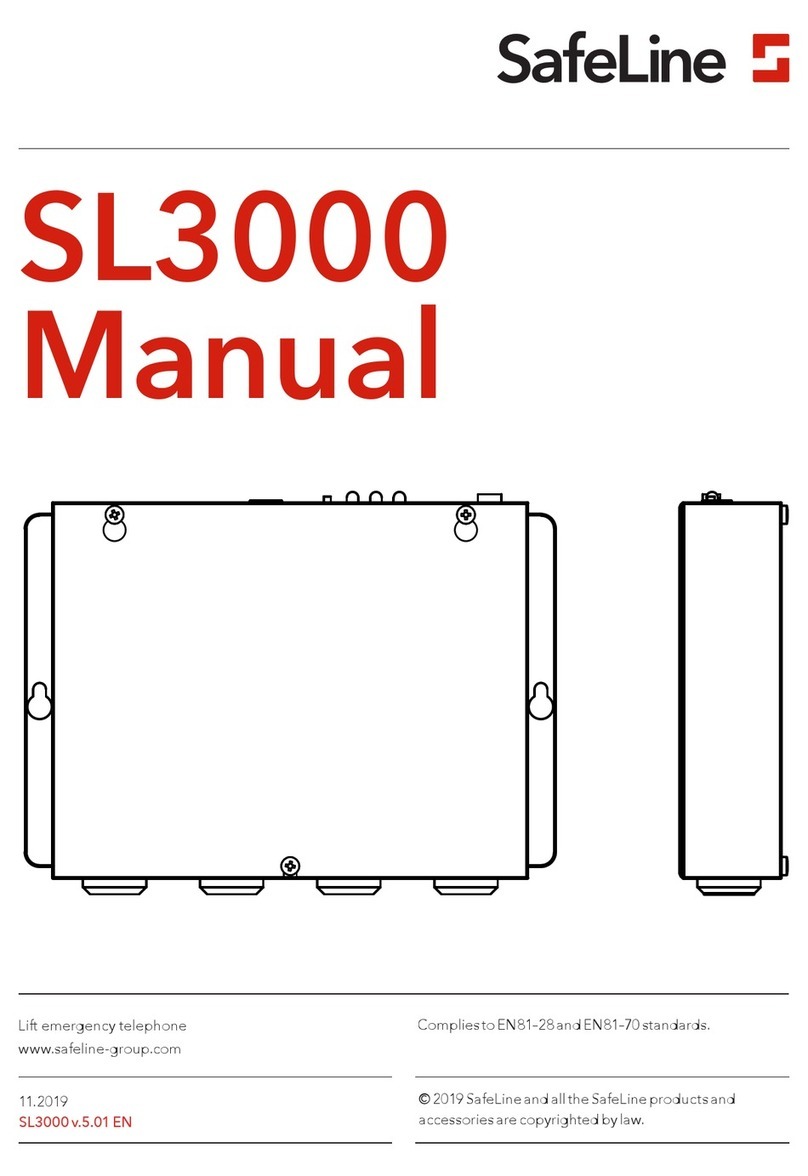

44 SL1 v.2.1.0 EN

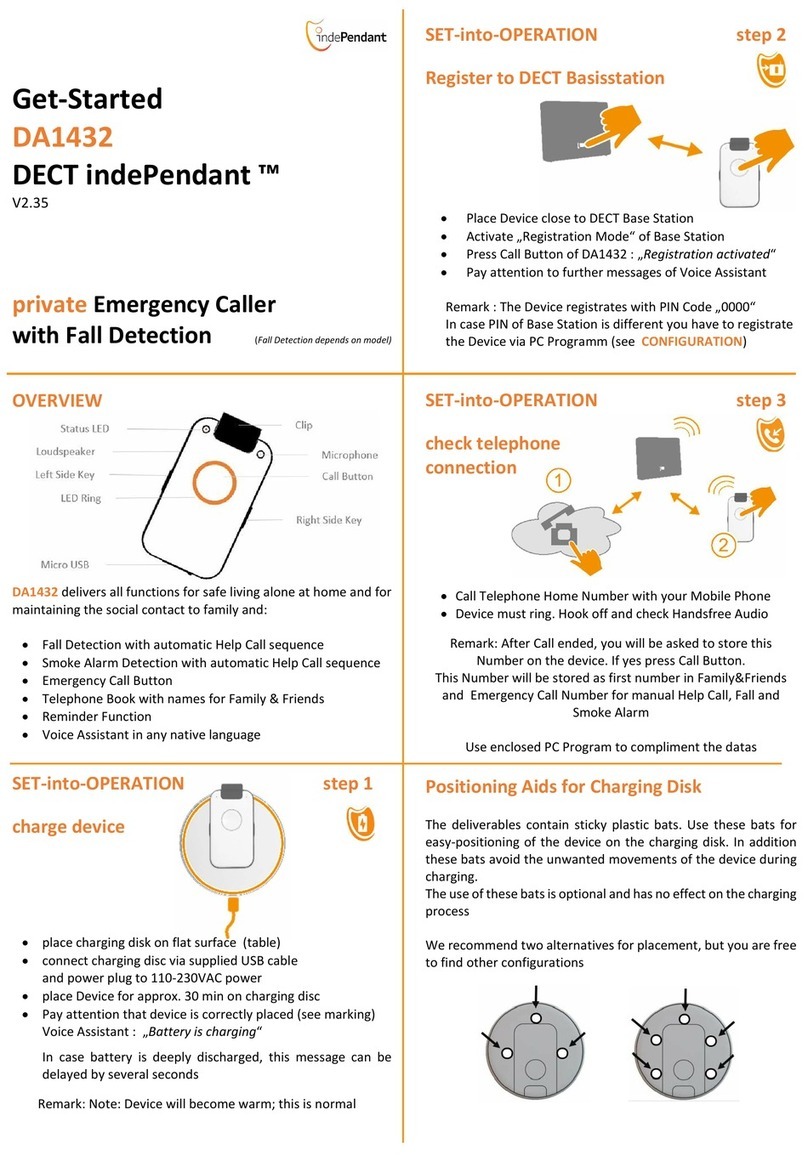

This unit was built with state-

of-the-art technology and to

generally recognised safety

related technical standards

currently applicable. These

installation instructions are

to be followed by all people

working with the unit, in both

installation and maintenance.

It is extremely important that

these installation instructions

are made available at all times

to the relevant technicians,

engineers or servicing and

maintenance personnel. The

basis prerequisite for safe

handling and trouble free

operation of this system is a

sound knowledge of the basic

and special safety regulations

concerning conveyor techno-

logy, and elevators in particular.

The unit may only be used for

its intended purpose. Note in

particular that, no unauthorised

changes or additions may be

made inside the unit or indivi-

dual components.

Exclusion of liability

The manufacturer is not liable

with respect to the buyer of

this product or to third parties

for damage, loss, costs or work

incurred as a result of accidents,

misuse of the product, incorrect

installation or illegal changes,

repairs or additions. Claims

under warranty are likewise

excluded in such cases. The

technical data is the latest

available. The manufacturer

accepts no liability arising from

printing errors, mistakes or

changes.

Declaration of conformity

Download ”The declaration of

conformity” at our website:

www.safeline-group.com

Safety Precautions!

- Only trained professionals,

who are authorised to work on

the equipment, should install

and con gure this product.

- This quality product is dedi-

cated for the lift industry. It has

been designed and manufactu-

red to be used for its speci ed

purpose only. If it is to be used

for any other purpose, SafeLine

must be contacted in advance.

- It should not be modi ed

or altered in any way, and

should only be installed and

con gured strictly following the

procedures described in this

manual.

- All applicable health and

safety requirements and

equipment standards should be

considered and strictly adhered

to when installing and con -

guring this product.

- After installation and con -

guration this product and the

operation of the equipment

should be fully tested to ensure

correct operation before the

equipment is returned to

normal use.

Electrical and electronic

products may contain materials,

parts and units that can be

dangerous for the environment

and human health. Please

inform yourself about the local

rules and disposal collection

system for electrical and

electronic products. The correct

disposal of your old product

will help to prevent negative

consequences for the environ-

ment and human health.

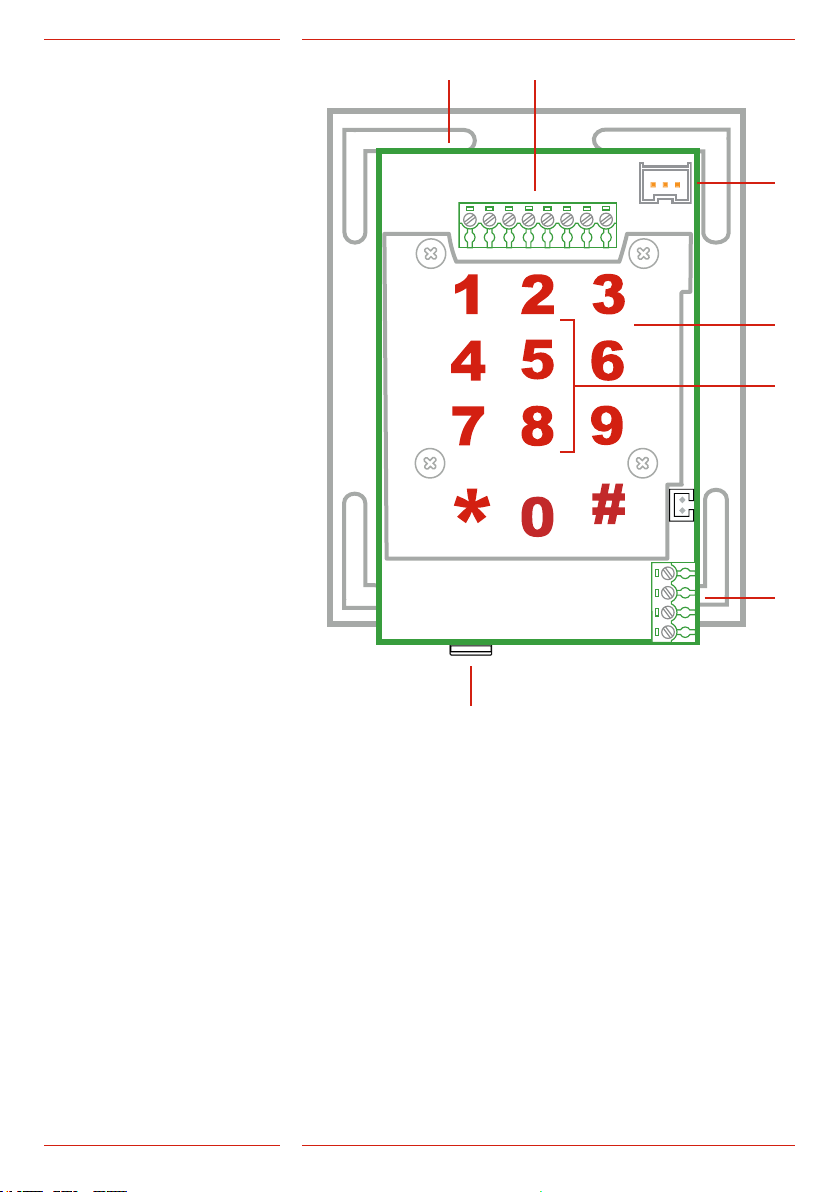

General

information