PHP400 Analogue Help Point. 2

CONTENTS

1. Safety and Care Information.....................................................................................3

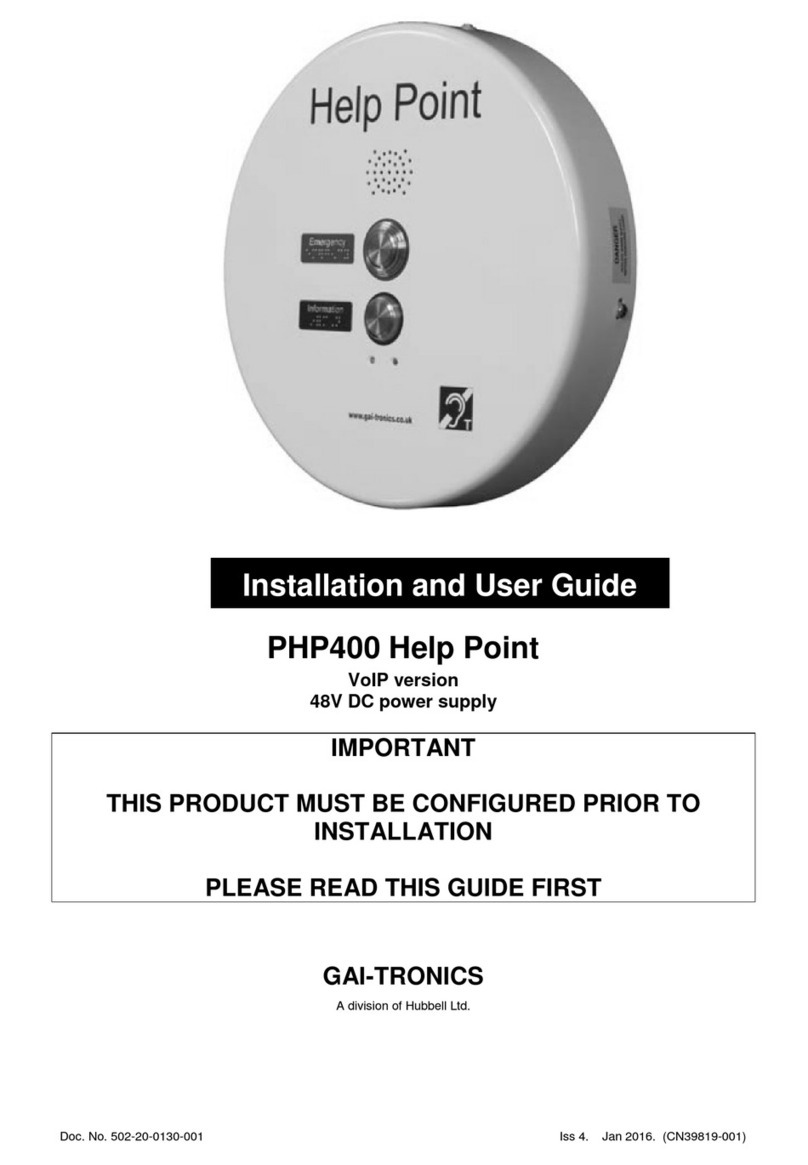

2. Product Description and Features ............................................................................3

3. Operation / Testing...................................................................................................4

3.1. Making a Call................................................................................................4

3.2. Answering calls.............................................................................................4

3.3. Ending the Call .............................................................................................4

3.4. Call timer ......................................................................................................5

3.5. Semi Duplex Operation.................................................................................5

4. SMART features.......................................................................................................5

5. Installation and dimensions ......................................................................................6

5.1. General.........................................................................................................6

5.2. Units dimensions and weight ........................................................................6

5.3. Site requirements..........................................................................................6

5.4. Opening the Unit...........................................................................................6

5.5. Installation method........................................................................................7

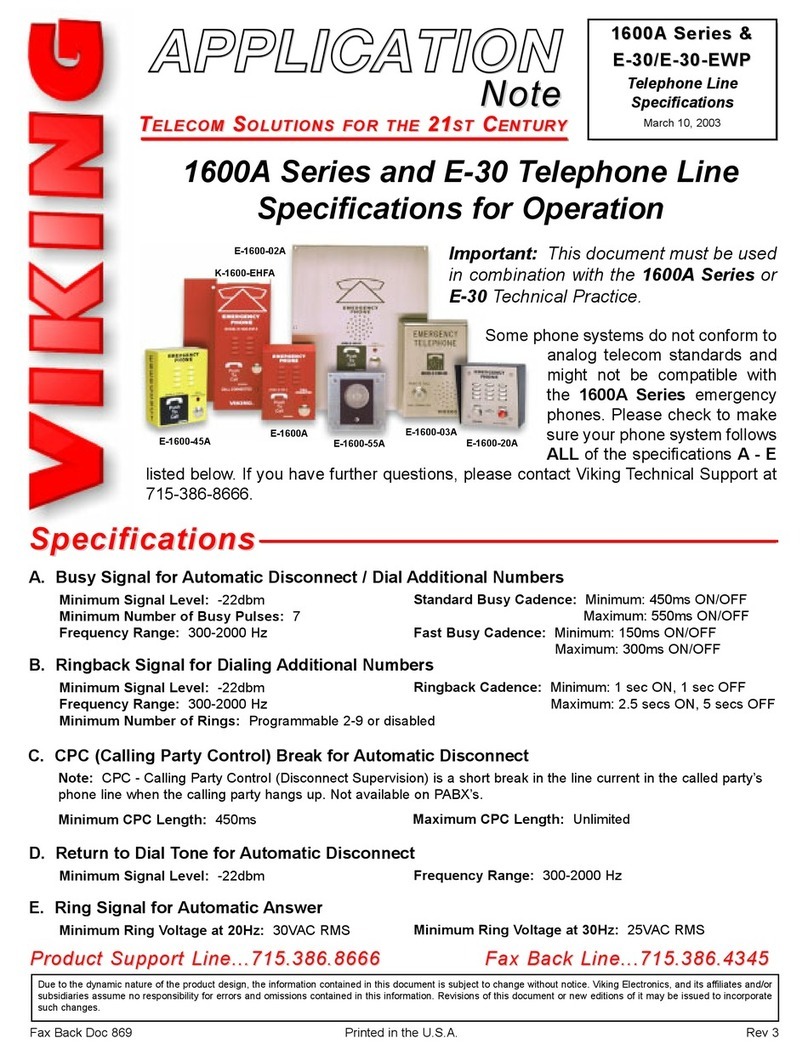

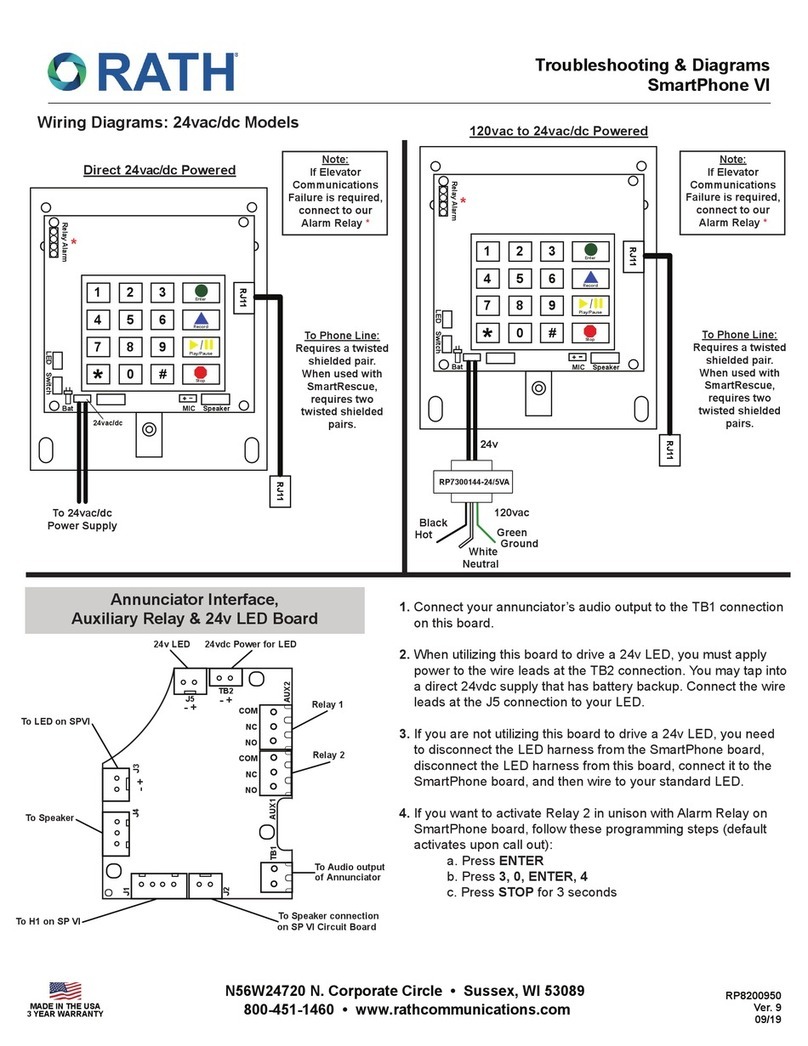

6. Connections .............................................................................................................8

6.1. Connections between Front and Rear Sections............................................8

6.2. Power connections........................................................................................8

6.3. Earth connections.........................................................................................8

6.4. Telephone Module Connections....................................................................9

6.5. Internal power connections...........................................................................9

6.6. Relay outputs................................................................................................9

6.7. Optional external inputs ..............................................................................10

7. Programming and Option Settings..........................................................................11

7.1. Quick Programming Guide (using a tone phone).........................................11

7.2. Further programming options......................................................................12

7.3. TMA............................................................................................................13

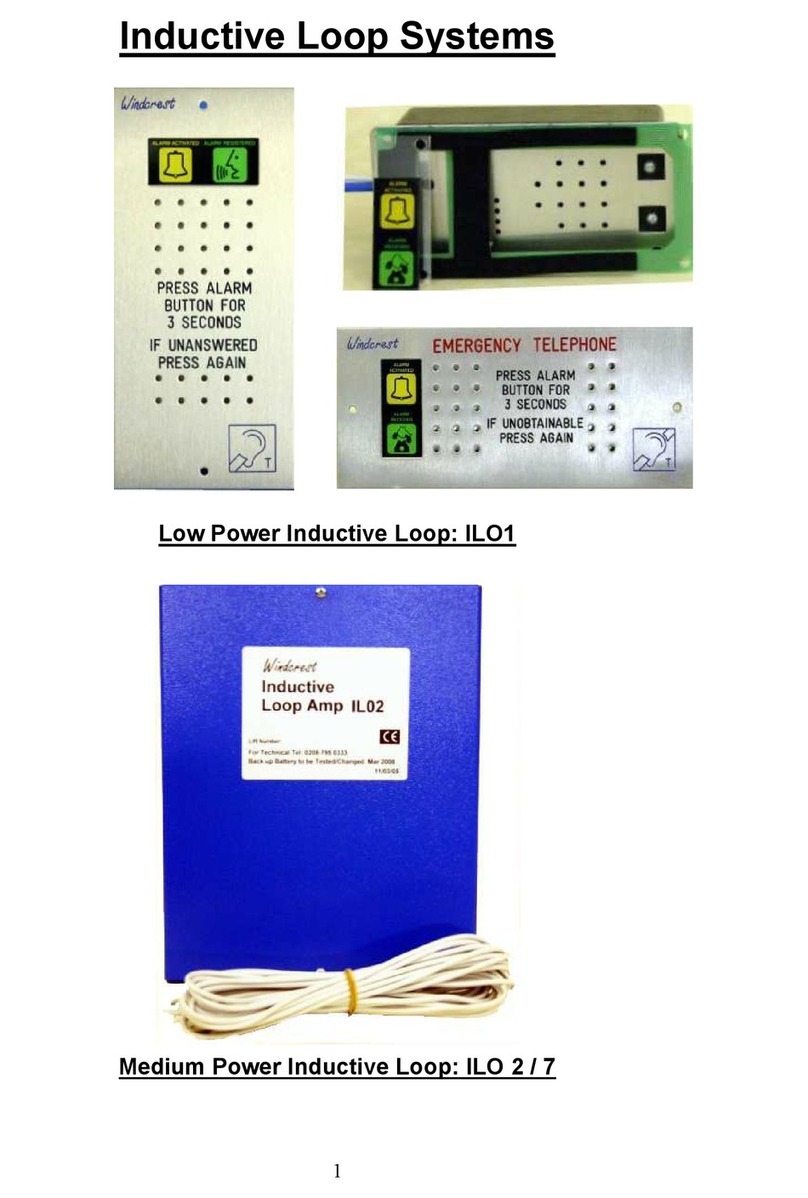

8. Induction Loop Amplifier.........................................................................................13

9. Cleaning.................................................................................................................13

9.1. Normal Cleaning.........................................................................................13

9.2. Stainless Steel Push-buttons......................................................................13

9.3. Graffiti.........................................................................................................13

9.4. Anti-Graffiti Coating.....................................................................................13

10. Aftercare.................................................................................................................14

11. Repairs and Spare Parts. .......................................................................................14

12. Technical Specifications.........................................................................................15

13. CE Declaration.......................................................................................................18