MULTILUBE

MLP

HMLU2CEN.doc 21.03.2006 Rev. 2C

4 (5)

Note This equipment has been tested and found to comply with the limits for

Class B digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

in residential installation. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not

occur in a particular installation. If this device does cause harmful

interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

- reorient or relocate the receiving antenna

- increase the separation between the equipment and receiver

- connect the equipment into an outlet on a circuit different from that to

which the receiver is connected

- Consult the dealer or an experienced radio/TV technician for help.

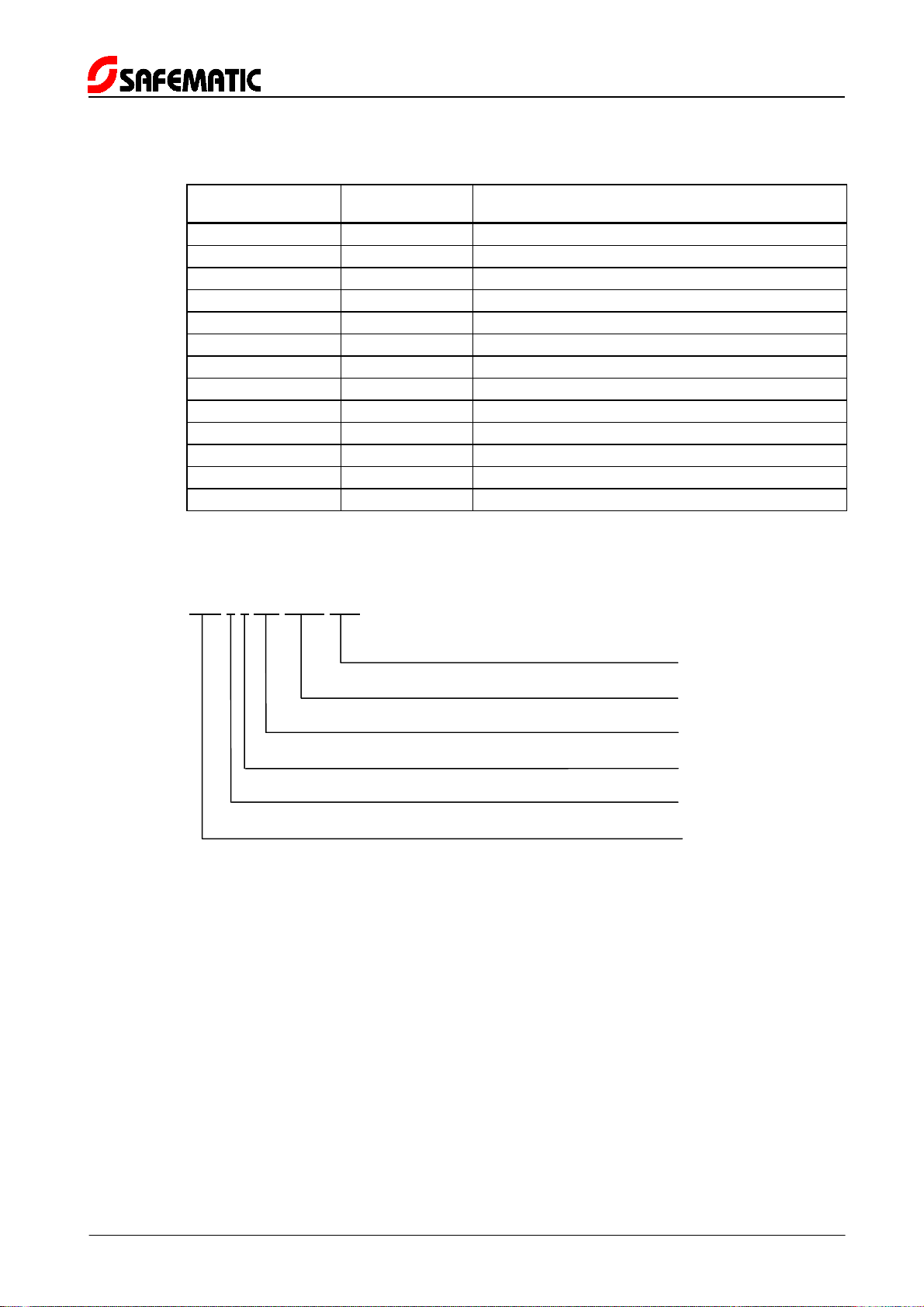

4.4 Connections

Input

•pressure switch, 2 pcs, closing contact

or pressure transmitter, 2 pcs, 4–20 mA / 0–250 bar, 2-wire type

•interlocking, lubrication points in operation when external interlocking switch is open

Output

•lubricant, 2 pcs, female thread R ¼”

•alarm, potential-free contact open in alarm mode, load 115V / 1A max.

Cable channels in the intermediate plate

•PG 13,5 cable gland, 2 pcs, for 6-12 mm cable diameters

•PG 11 cable gland, 2 pcs, for 4-10 mm cable diameters