www.salukitec.com

Content

1Safety Tips.............................................................................................................................................................................7

1.1 General Safety Summary.................................................................................................................................................7

1.2 Safety Information.............................................................................................................................................................8

1.3 System Symbols...............................................................................................................................................................8

1.4 System Terms..................................................................................................................................................................8

1.5 Product Scrapping............................................................................................................................................................8

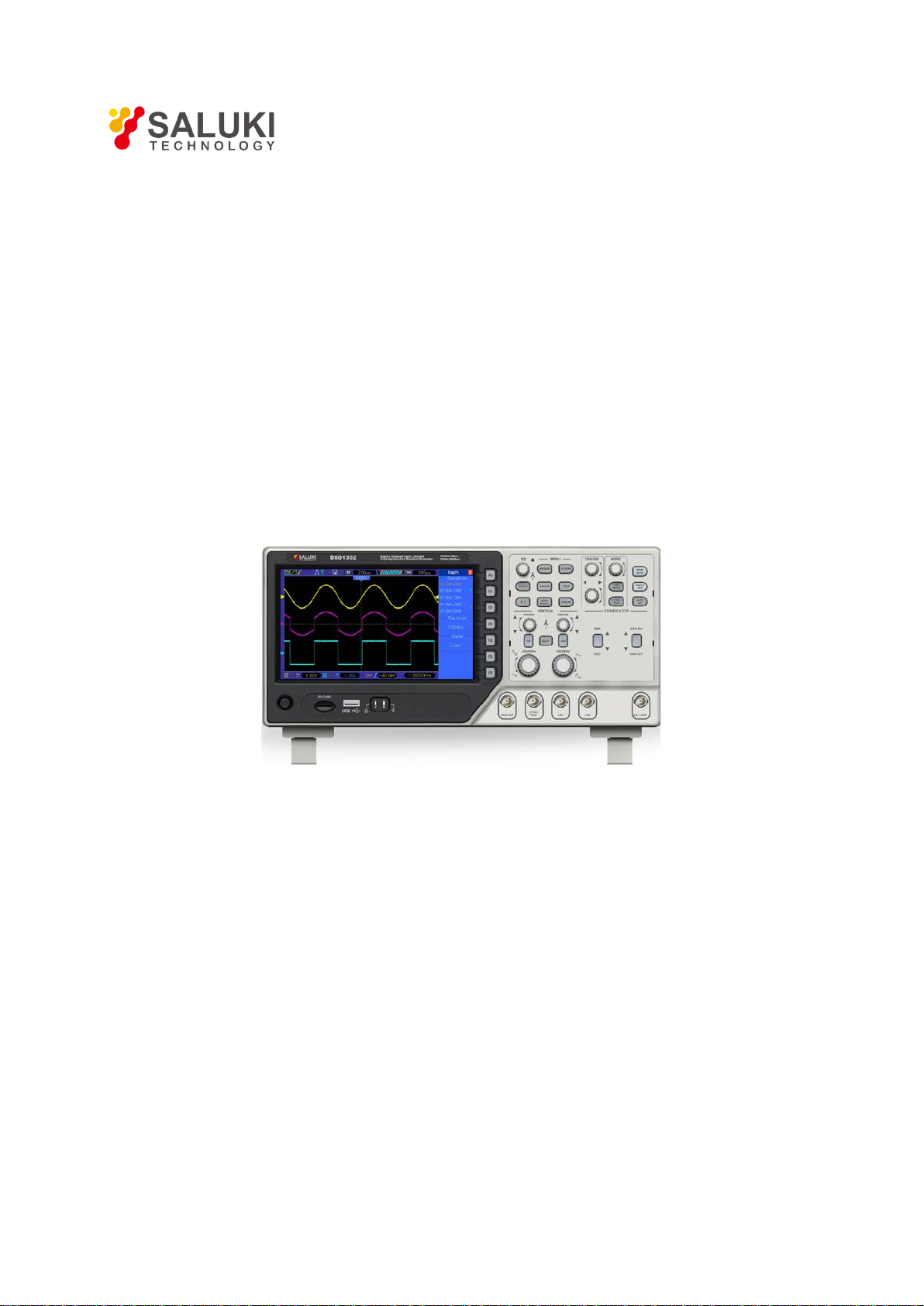

2Overview................................................................................................................................................................................9

2.1 Brief Introduction...............................................................................................................................................................9

2.2 Help System.....................................................................................................................................................................9

3Getting Started Guide...........................................................................................................................................................11

3.1 Installation......................................................................................................................................................................11

3.2 Functional Check............................................................................................................................................................11

3.3 Probe Examination.........................................................................................................................................................12

3.4 Manual Probe Compensation.........................................................................................................................................12

3.5 Probe Attenuation Setting...............................................................................................................................................13

3.6 Self Calibration...............................................................................................................................................................14

4Main Feature Description.....................................................................................................................................................15

4.1 Oscilloscope Setup.........................................................................................................................................................15

4.2 Trigger............................................................................................................................................................................15

4.3 Data Acquisition..............................................................................................................................................................16

4.4 Waveform Scaling and Positioning.................................................................................................................................17

4.5 Waveform Measurement................................................................................................................................................18

5Basic Operation....................................................................................................................................................................19

5.1 User Interface.................................................................................................................................................................19

5.2 Horizontal System...........................................................................................................................................................21

5.3 Vertical Controls.............................................................................................................................................................23

5.4 Trigger Controls..............................................................................................................................................................30

5.5 Menu and Option Buttons...............................................................................................................................................37

5.6 Fast Action Buttons.........................................................................................................................................................46

5.7 Multi-functional Buttons..................................................................................................................................................48

5.8 Signal Connectors..........................................................................................................................................................48

6Application Examples...........................................................................................................................................................49

6.1 Example 1: Taking Simple Measurements.....................................................................................................................49

6.2 Example 2: Taking Cursor Measurements......................................................................................................................51

6.3 Example 3: Analyzing Input Signals to Eliminate Random Noise...................................................................................54

6.4 Example 4: Capturing Single-shot Signal.......................................................................................................................55

6.5 Example 5: Using X-Y Mode...........................................................................................................................................56

6.6 Example 6: Triggering on Pulse Width...........................................................................................................................57

6.7 Example 7: Triggering on Video Signal..........................................................................................................................58