2

Contents

VEGAMET 625 • Double channel HART

28970-EN-130701

Contents

1 About this document

1.1 Function ........................................................................................................................... 4

1.2 Target group ..................................................................................................................... 4

1.3 Symbolism used............................................................................................................... 4

2 For your safety

2.1 Authorised personnel ....................................................................................................... 5

2.2 Appropriate use................................................................................................................ 5

2.3 Warning about incorrect use............................................................................................. 5

2.4 General safety instructions............................................................................................... 5

2.5 Safety label on the instrument .......................................................................................... 5

2.6 CE conformity................................................................................................................... 6

2.7 Safety instructions for Ex areas ........................................................................................ 6

2.8 OverllprotectionaccordingtoWHG ............................................................................... 6

2.9 Environmental instructions ............................................................................................... 6

3 Product description

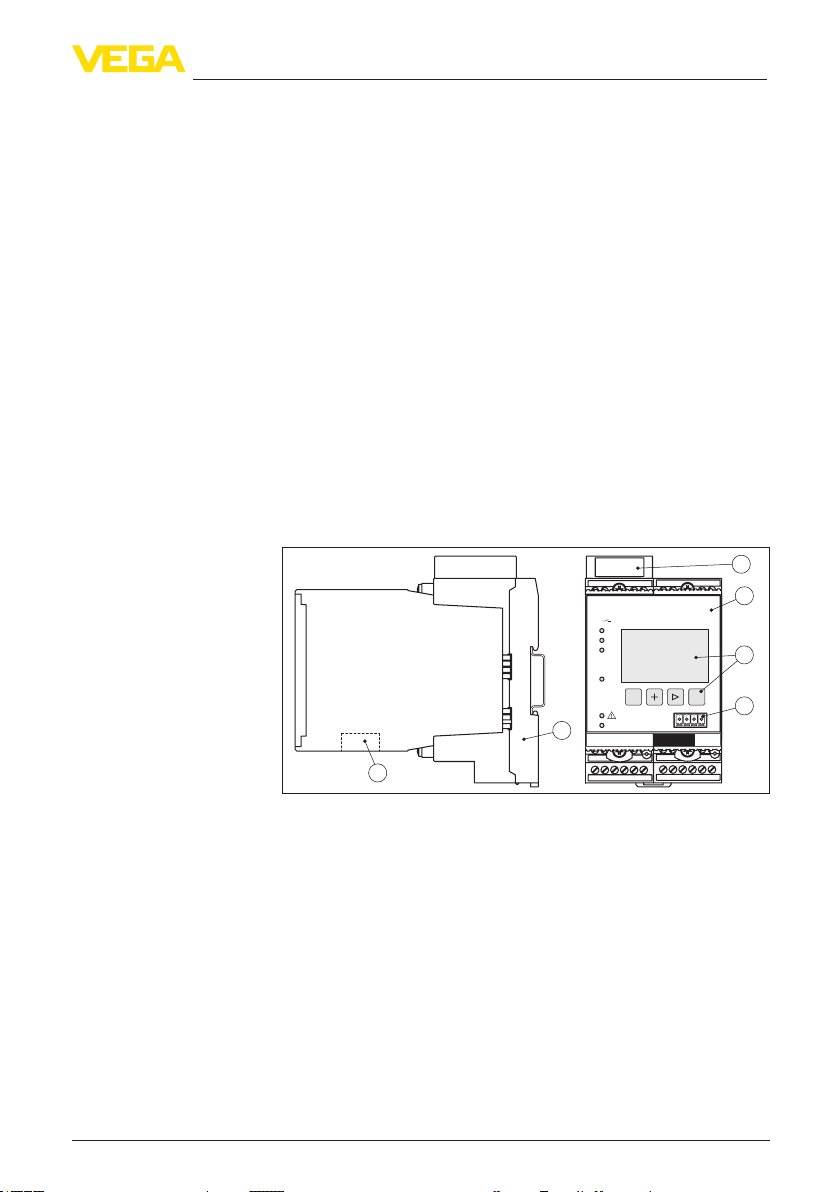

3.1 Conguration.................................................................................................................... 7

3.2 Principle of operation........................................................................................................ 8

3.3 Adjustment ....................................................................................................................... 8

3.4 Packaging, transport and storage..................................................................................... 9

4 Mounting

4.1 General instructions ....................................................................................................... 10

4.2 Mounting instructions ..................................................................................................... 10

5 Connecting to power supply

5.1 Preparing the connection ............................................................................................... 12

5.2 Connection procedure.................................................................................................... 12

5.3 Wiring plan ..................................................................................................................... 14

6 Setup with the integrated display and adjustment unit

6.1 Adjustment system......................................................................................................... 16

6.2 Setup steps .................................................................................................................... 17

6.3 Menu schematic............................................................................................................. 27

7 Setup with PACTware

7.1 Connect the PC.............................................................................................................. 35

7.2 Parameter adjustment with PACTware............................................................................ 37

7.3 Setup web server/e-mail, remote enquiry....................................................................... 38

8 Application examples

8.1 Levelmeasurementinacylindricaltankwithoverllprotection/dryrunprotection ......... 39

8.2 Weir control of a water power station.............................................................................. 40

8.3 Interface measurement with VEGAFLEX........................................................................ 42

8.4 Pump control 1/2 (running time controlled)..................................................................... 43

8.5 Tendency recognition ..................................................................................................... 45

8.6 Flow measurement......................................................................................................... 46

9 Maintenanceandfaultrectication

9.1 Maintenance .................................................................................................................. 49

9.2 Rectify faults................................................................................................................... 49

9.3 Instrument repair ............................................................................................................ 51