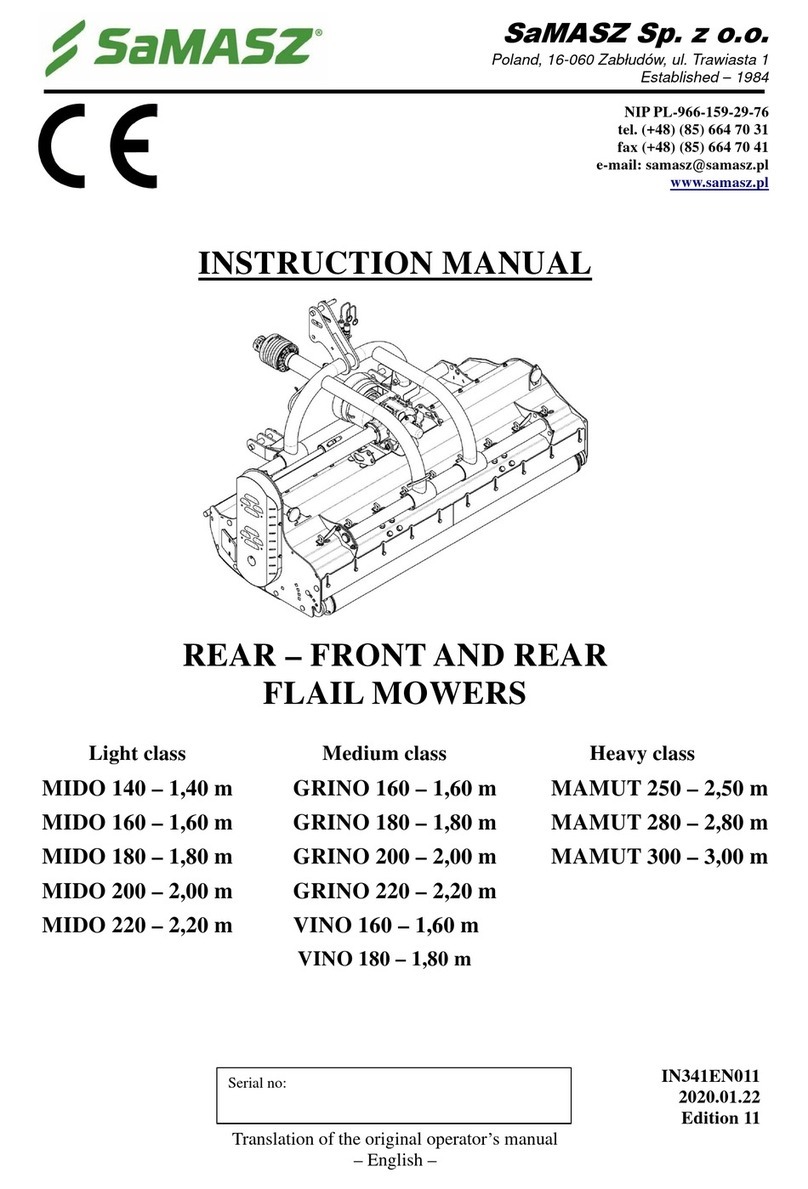

Operator’s manual

Front flail mowers

NANO 150, NANO 150 H

- 1 -

TABLE OF CONTENTS

1. DEVICE IDENTIFICATION ....................................................................................................................2

2. INTRODUCTION.......................................................................................................................................2

3. INTENDED USE OF THE FLAIL MOWER ..........................................................................................3

3.1. Technical data........................................................................................................................................3

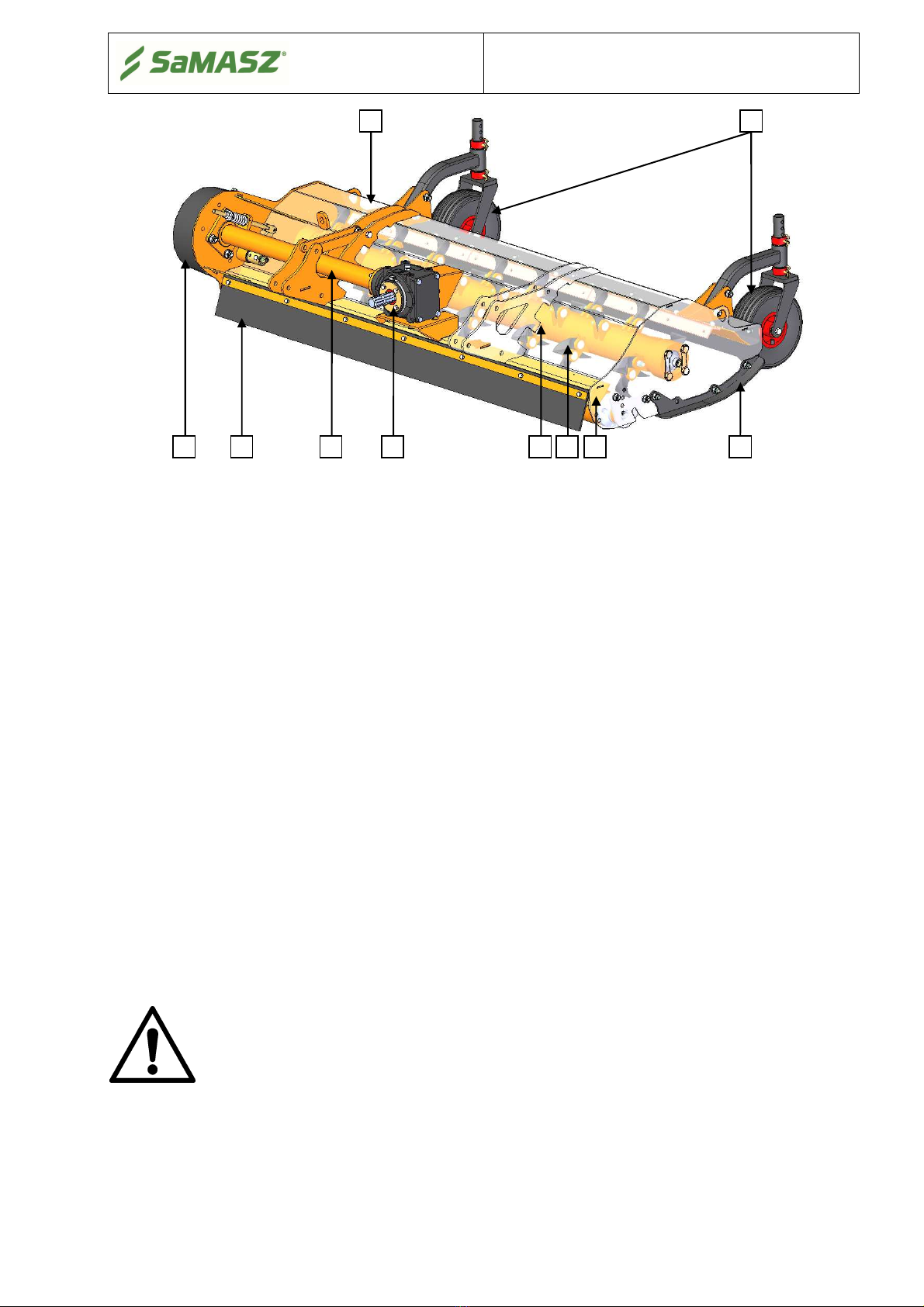

3.2. Construction and operation....................................................................................................................4

3.3. Equipment and spare parts.....................................................................................................................5

3.3.1. Flail knives applicable in NANO flail mowers ................................................................................6

4. SAFETY ADVICE AND WARNING .......................................................................................................7

4.1. Safety rules and regulations...................................................................................................................7

4.2. Qualifications of operator......................................................................................................................9

4.3. Conditions of connecting mower with vehicle ......................................................................................9

4.4. Transport................................................................................................................................................9

4.4.1. Relocating flail mower onto another vehicle for transport.............................................................10

4.5. Operating parts ....................................................................................................................................11

4.6. PTO shaft.............................................................................................................................................11

4.7. Hydraulic assembly .............................................................................................................................11

4.8. Residual risk ........................................................................................................................................12

4.8.1. Residual risk evaluation .................................................................................................................13

4.9. Warning signs and their meanings.......................................................................................................14

5. OPERATION OF THE MOWER ...........................................................................................................16

5.1. Connecting the flail mower to the vehicle...........................................................................................16

5.1.1. Connecting the NANO 150 H flail mower to the vehicle ..............................................................16

5.1.2. Connecting the NANO 150 flail mower to the vehicle ..................................................................17

5.1.3. Connecting the PTO shaft (for NANO 150)...................................................................................18

5.2. Preparing the NANO 150 H flail mower to transport..........................................................................19

5.2.1. Preparing the NANO 150 H flail mower to transport ....................................................................19

5.2.2. Preparing the NANO 150 flail mower to transport ........................................................................19

5.3. Preparing the mower for operation......................................................................................................20

5.3.1. Preparing the NANO 150 H flail mower for operation..................................................................20

5.3.2. Preparing the NANO 150 flail mower for operation......................................................................20

5.4. Operation .............................................................................................................................................20

5.4.1. Basic information on mowing ........................................................................................................20

5.4.2. Removing clogging and jams .........................................................................................................21

5.5. Dismounting the mower from the vehicle ...........................................................................................21

6. MOUNTING AND SETTINGS ...............................................................................................................22

6.1. Setting the mowing height...................................................................................................................22

6.2. Maintenance ........................................................................................................................................22

6.2.1. Controlling belt tautness in the belt gear........................................................................................22

6.2.2. Checking the flail blades ................................................................................................................23

6.2.3. Everyday maintenance ...................................................................................................................23

6.2.4. After-season maintenance and storing............................................................................................24

6.2.5. Restarting the machine after storing period....................................................................................24

7. LUBRICATION ........................................................................................................................................25

7.1. Angle gear (for NANO 150)................................................................................................................25

7.2. Flail and copying shaft ........................................................................................................................25

8. MALFUNCTIONS AND THEIR CORRECTION................................................................................26

9. MOWER REPAIR AND DISPOSAL .....................................................................................................26

9.1. Repair ..................................................................................................................................................27

9.2. Disassembly and cassation ..................................................................................................................27

10. WARRANTY CARD ................................................................................................................................27

11. WARRANTY TERMS..............................................................................................................................28

11.1. Warranty terms procedures ...............................................................................................................28

11.2. Warranty repairs record ....................................................................................................................30