Operating manual

Rear disc mower with central suspension

- hydro-pneumatic or spring suspension

- 1 -

1. IDENTIFYING THE MACHINE ....................................................................................................................................2

2. INTRODUCTION .............................................................................................................................................................2

3. PROPER AND INTENDED USE.....................................................................................................................................3

3.1. Technical data ................................................................................................................................................................4

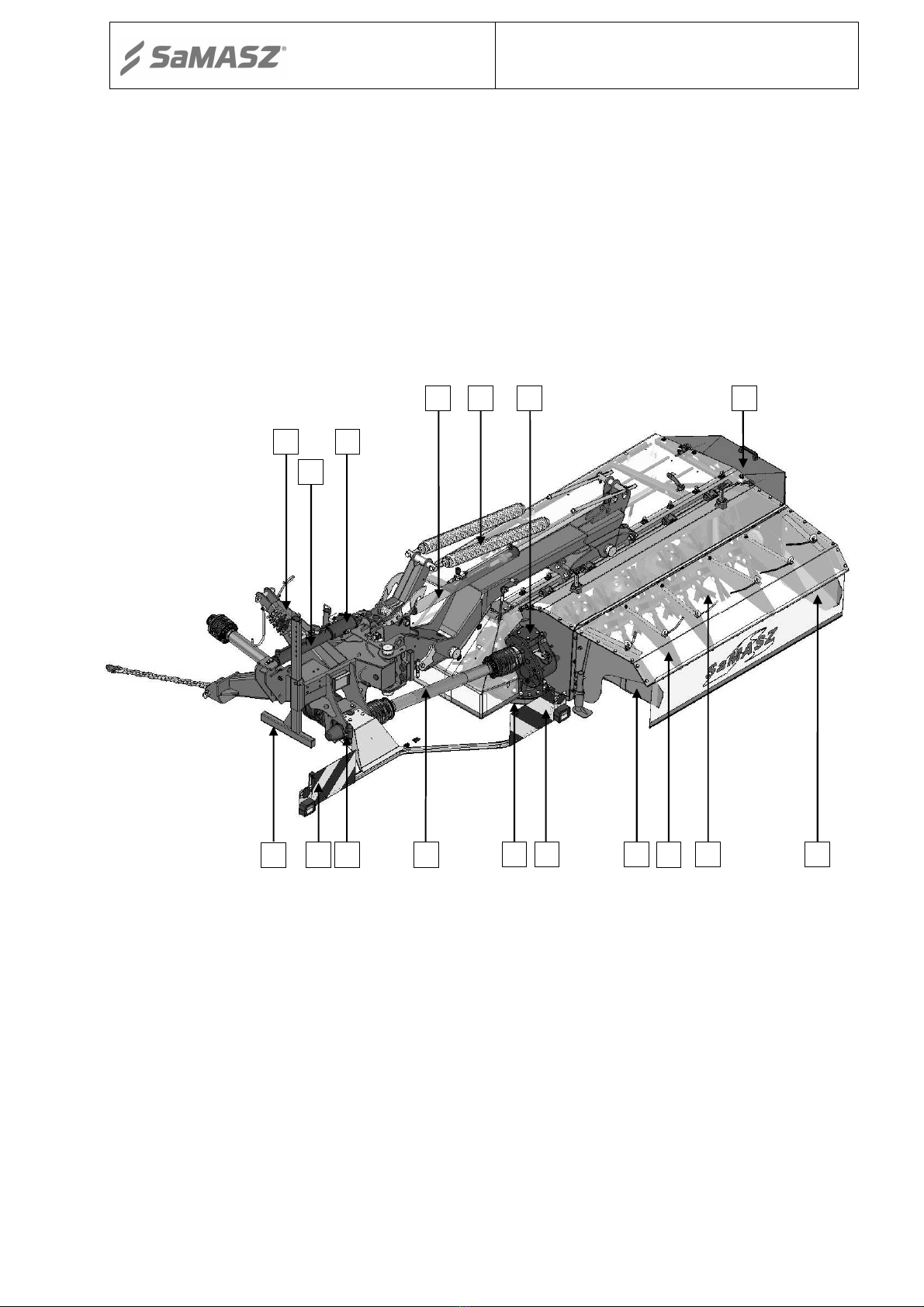

3.2. Design and working principle........................................................................................................................................6

3.3. Standard equipment and spare parts...............................................................................................................................9

4. SAFETY PRECAUTIONS..............................................................................................................................................10

4.1. General safety rules and regulations ............................................................................................................................11

4.2. Conditions of mounting mower on tractor ...................................................................................................................12

4.3. Transport......................................................................................................................................................................12

4.3.1. Placing the mower onto a transport vehicle ........................................................................................................13

4.4. Working parts .............................................................................................................................................................. 14

4.5. PTO shaft ..................................................................................................................................................................... 14

4.6. Safety curtains.............................................................................................................................................................. 14

4.7. Residual risk ................................................................................................................................................................15

4.7.1. Danger of machine entanglement........................................................................................................................15

4.7.2. Danger of cutting injury......................................................................................................................................15

4.7.3. Danger of injury from liquid ejection out of hydraulic system ...........................................................................15

4.7.4. Forbidden actions................................................................................................................................................ 15

4.7.5. Residual risk assessment ..................................................................................................................................... 15

4.8. Safety labels and their meaning ...................................................................................................................................16

4.9. Design and operation of hydraulic safety breakaway device .......................................................................................20

5. OPERATION OF THE MOWER ..................................................................................................................................21

5.1. Attaching the mower to the tractor...............................................................................................................................21

5.2. Mounting PTO shaft .................................................................................................................................................... 22

5.3. Preparing mower for operation – mower with hydro-pneumatic suspension ............................................................... 23

5.3.1. Gas pressure in the accumulator and in the entire system for each mower model .............................................. 24

5.4. Preparing mower for operation – mower with spring suspension ................................................................................ 24

5.5. Operating the mower....................................................................................................................................................25

5.5.1. Essential information concerning mowing.......................................................................................................... 25

5.5.2. Mower clogging ..................................................................................................................................................26

5.6. Preparing the mower for transport ...............................................................................................................................26

5.7. Preparing the mower for transport on public roads ......................................................................................................27

5.8. Moving from transport to working position................................................................................................................. 28

5.9. Disconnecting mower from tractor ..............................................................................................................................29

6. MOUNTING AND ADJUSTMENTS ............................................................................................................................29

6.1. Assembling / disassembling main frames ....................................................................................................................29

6.2. Mounting and timing of cutting blades ........................................................................................................................30

6.3. Blade replacement........................................................................................................................................................30

6.4. Adjusting the cutterbar................................................................................................................................................. 31

6.5. Setting mowing height ................................................................................................................................................. 33

6.6. Use and adjustment of load reducing chain..................................................................................................................34

6.7. Adjusting cutterbar’s pressure on the ground by means of support springs.................................................................34

6.8. Adjustment of the clearance between the cover and the roller of the conditioner........................................................35

6.9. Replacing conditioner tines..........................................................................................................................................35

6.10. Adjusting force of the pressure of roller conditioner ................................................................................................... 36

6.11. Maintenance and service..............................................................................................................................................37

6.11.1. Checking the blades and blade holders ...............................................................................................................37

6.11.2. Checking the tension of tine and roller conditioners’ driving chain.................................................................... 37

6.11.3. Daily maintenance...............................................................................................................................................38

6.11.4. After-season maintenance and storing of machine..............................................................................................38

7. LUBRICATION............................................................................................................................................................... 39

7.1. Cutterbar ......................................................................................................................................................................39

7.2. Intersecting axis gears..................................................................................................................................................39

7.3. Roller conditioner’s gearbox........................................................................................................................................40

7.4. Bearings .......................................................................................................................................................................41

7.5. Risks present when lubricating ....................................................................................................................................41

8. MALFUNCTIONS AND THEIR REPAIRS.................................................................................................................42

9. DISASSEMBLY AND WITHDRAWAL FROM USE .................................................................................................43

9.1. Scrapping .....................................................................................................................................................................43

10. HYDRAULIC SCHEME.................................................................................................................................................43

10.1. Hydraulic scheme of rear disk mower with swath conditioner ....................................................................................43

10.2. Hydraulic scheme of rear disk mower with hydro-pneumatic suspension ...................................................................44

11. WARRANTY CARD....................................................................................................................................................... 45

12. WARRANTY TERMS .................................................................................................................................................... 45

12.1. Warranty claims procedures.........................................................................................................................................45

12.2. Warranty repairs record ...............................................................................................................................................46

APPENDIX CALCULATING AXIS LOAD ..........................................................................................................................47