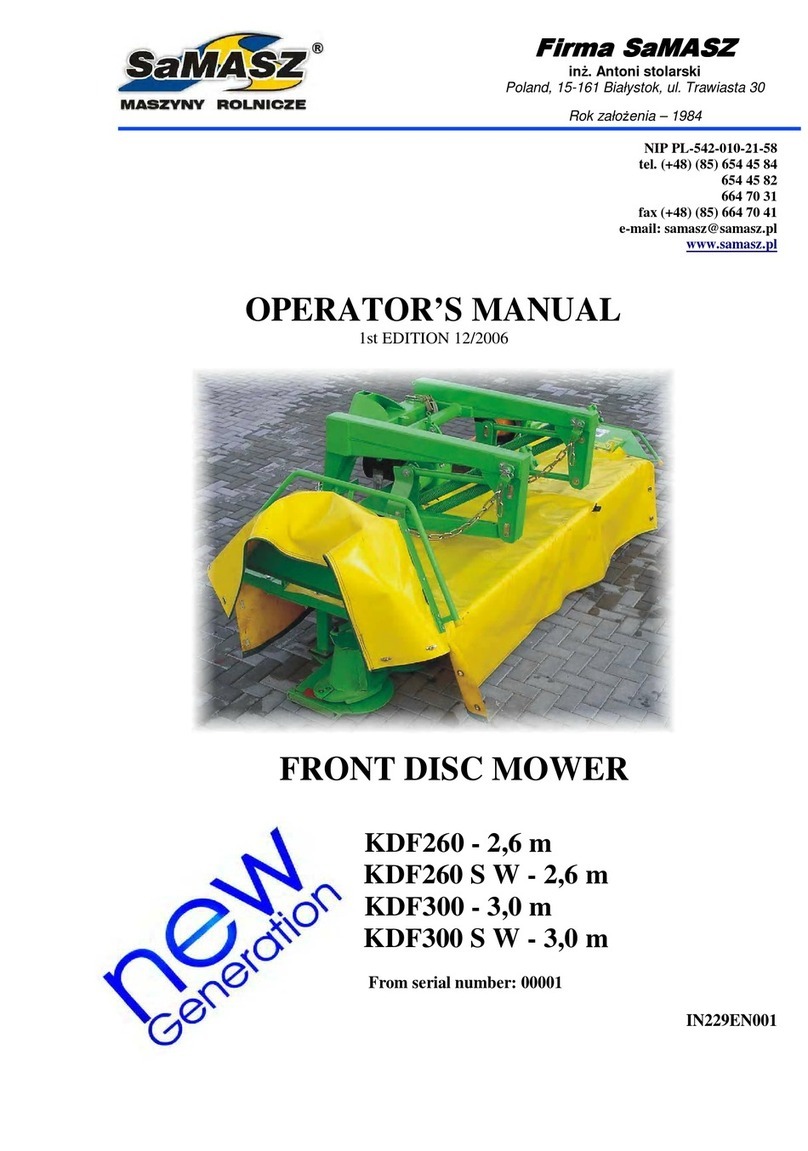

Operator’s manual

Double-sided disc mowers

with central suspension

- 1 -

Contents page

1.

IDENTIFYING THE MACHINE .............................................................................................2

2.

INTRODUCTION.......................................................................................................................2

3.

PROPER USE..............................................................................................................................3

3.1. Technical data.....................................................................................................................................4

3.2. Design and working principle.............................................................................................................5

3.3. Standard equipment and spare parts....................................................................................................8

4.

SAFETY ADVICE......................................................................................................................9

4.1. Safety rules and regulations................................................................................................................9

4.2. Transport...........................................................................................................................................10

4.2.1. Putting the mower onto another vehicle for transpor...................................................................10

4.3. Working parts ...................................................................................................................................11

4.4. PTO shaft..........................................................................................................................................11

4.5. Residual risk .....................................................................................................................................11

4.6. Safety decals and their meaning .......................................................................................................13

4.7. Design and operation of safety breakaway device............................................................................17

5.

OPERATION.............................................................................................................................17

5.1. Attaching the mower to the tractor ...................................................................................................17

5.2. Preparing the mower for transport....................................................................................................18

5.3. Preparing the mower for transport on public roads...........................................................................20

5.4. Mounting PTO shaft .........................................................................................................................20

5.5. Switching from transport to working position..................................................................................21

5.6. Preparing the mower for work..........................................................................................................22

5.7. Operation (mowing)..........................................................................................................................22

5.7.1. Essential information concerning mowing ..................................................................................23

5.7.2. Taking turns over swaths.............................................................................................................23

5.8. Storing...............................................................................................................................................24

6.

MOUNTING AND ADJUSTMENTS .....................................................................................24

6.1. Mounting and timing of the knives...................................................................................................24

6.2. Replacing the knives.........................................................................................................................25

6.3. Adjusting the cutterbar......................................................................................................................25

6.4. Adjusting space between tine conditioner’s mask and its shaft........................................................28

6.5. Replacing conditioner’s tines............................................................................................................28

6.6. Adjusting force of the pressure of roller conditioner........................................................................29

6.7. Maintenance and service...................................................................................................................29

6.7.1. Checking the knives and knife holders........................................................................................29

6.7.2. Checking the tension of tine and roller conditioners’ driving chain............................................30

6.7.3. Daily maintenance .......................................................................................................................30

6.7.4. After-season maintenance............................................................................................................30

6.8. Conveyor control and adjustment.....................................................................................................31

6.8.1. Cleaning method of belt and rollers.............................................................................................31

6.8.2. Conveyor belt replacement and adjustment instruction...............................................................32

7.

LUBRICATION........................................................................................................................34

7.1. Cutterbar ...........................................................................................................................................34

7.2. Intersecting axis gears.......................................................................................................................34

7.3. Roller conditioner’s gearbox.............................................................................................................35

7.4. Chain drives of the roller and the scarifier........................................................................................36

7.5. Bearings and joints............................................................................................................................36

8.

DEFECTS AND THEIR REPAIRS........................................................................................37

9.

DISASSEMBLY AND WITHDRAWAL FROM USE..........................................................38

9.1. Disassembly......................................................................................................................................38

9.2. Scrapping..........................................................................................................................................38

10.

WARRANTY CARD................................................................................................................38

11.

WARRANTY TERMS..............................................................................................................39

11.1. Warranty claims procedures .............................................................................................................39

11.2. Warranty repairs record ....................................................................................................................40