Page 3 81000V-90(L)

6.3 ERROR HANDLING

ERROR HANDLING determines the manner in which invalid

measurements are handled. Invalid measurements can occur when

the acoustic path of the sonic signal is blocked or internal circuits fail.

Acoustic blockage may be caused by rain drops, ice, snow, or other

debris on the transducers. When set to INCLUDE INVALID DATA, an

output always occurs. If CUSTOM serial output is used, an ERROR

CODE may be included in the output string to indicate an error

condition. When set to OMIT INVALID DATA, invalid measurements

are not output.

ERROR HANDLING: 2

-----------------

1) INCLUDE INVALID DATA

2) OMIT INVALID DATA

X) EXIT

6.4 SCALING MULTIPLIER

SCALING MULT sets overall scaling for UVW, 2D, and 3D wind

speed outputs. Azimuth and elevation angle are not effected. The

default value of 10000 represents a scaling multiplier of 1.0000.

Normally, this value should not be changed since each instrument

is calibrated in the YOUNG factory wind tunnel. Users who wish to

alter the scaling based on independent calibration assessment may

use this parameter to do so.

SCALING MULTIPLIER: 10000

ENTER NEW VALUE:

6.5 OUTPUT RATE

OUTPUT RATE sets the rate at which samples serially output.

Fast output rates and long serial output strings may require higher

baud rates in order to keep up with the outgoing data stream. See

SERIAL COMMUNICATION in SECTION 7 for additional details. If

AVERAGING is used, average results are available only after enough

output samples have been collected. See AVERAGING for details.

OUTPUT RATE 4Hz

--------------------

A) 4 HZ

B) 5 HZ

C) 8 HZ

D) 10 HZ

E) 16 HZ

F) 20 HZ

G) 32 HZ

X) EXIT TO MAIN MENU

6.6 POLL CHARACTER

POLL CHARACTER (ADDR) sets the address character for polled

operation (POLL CUSTOM or POLLED BINARY output formats).

Any printable ASCII character may be used to assign an address

that uniquely identies the instrument. When bussed on an RS‑485

network with other 81000 instruments, each one should have a

different address character.

POLL CHARACTER (ADDR): A

ENTER NEW CHARACTER:

To poll the 81000V, send MA! where A is the unique POLL

CHARACTER. The 81000 will respond with the POLL CHARACTER

and a space followed by the serial output string.

6.7 SERIAL OUTPUT FORMAT

SERIAL OUTPUT FORMAT sets the output string for serial output.

Preset and custom formats are available.

SERIAL OUTPUT FORMAT 1

------------------------------------

1) CUSTOM

3) NMEA (CHANGES OTHER PARAMETERS, SEE MANUAL)

4) POLLED CUSTOM

6) POLLED BINARY

X) EXIT TO MAIN MENU

CUSTOM

CUSTOM format allows the user to construct an ASCII-printable

serial output string. Long strings may require higher BAUD rates

or lower OUTPUT RATES. (See BAUD and OUTPUT RATE.)

Also, see UNITS. When CUSTOM is selected the following message

and sub-menu appear:

CURRENT SERIAL OUTPUT FORMAT:

789AB [ 3D-SPEED AZIMUTH ELEVATION SOS Ts ]

CONSTRUCT AN OUTPUT FORMAT BY SELECTING FROM THE LIST BELOW.

ELEMENTS MAY BE IN ANY ORDER. REFER TO MANUAL FOR DETAILS.

----------------------------------------------------------

1) VIN1

2) VIN2

3) VIN3

4) VIN4

5) UVW

6) 2D SPEED

7) 3D SPEED

8) AZIMUTH

9) ELEVATION

A) SOS

B) Ts

C) CHKSUM

E) ERR CODE

V) INTERNAL VOLTAGE

ENTER CUSTOM STRING (12 CHARACTERS MAX):

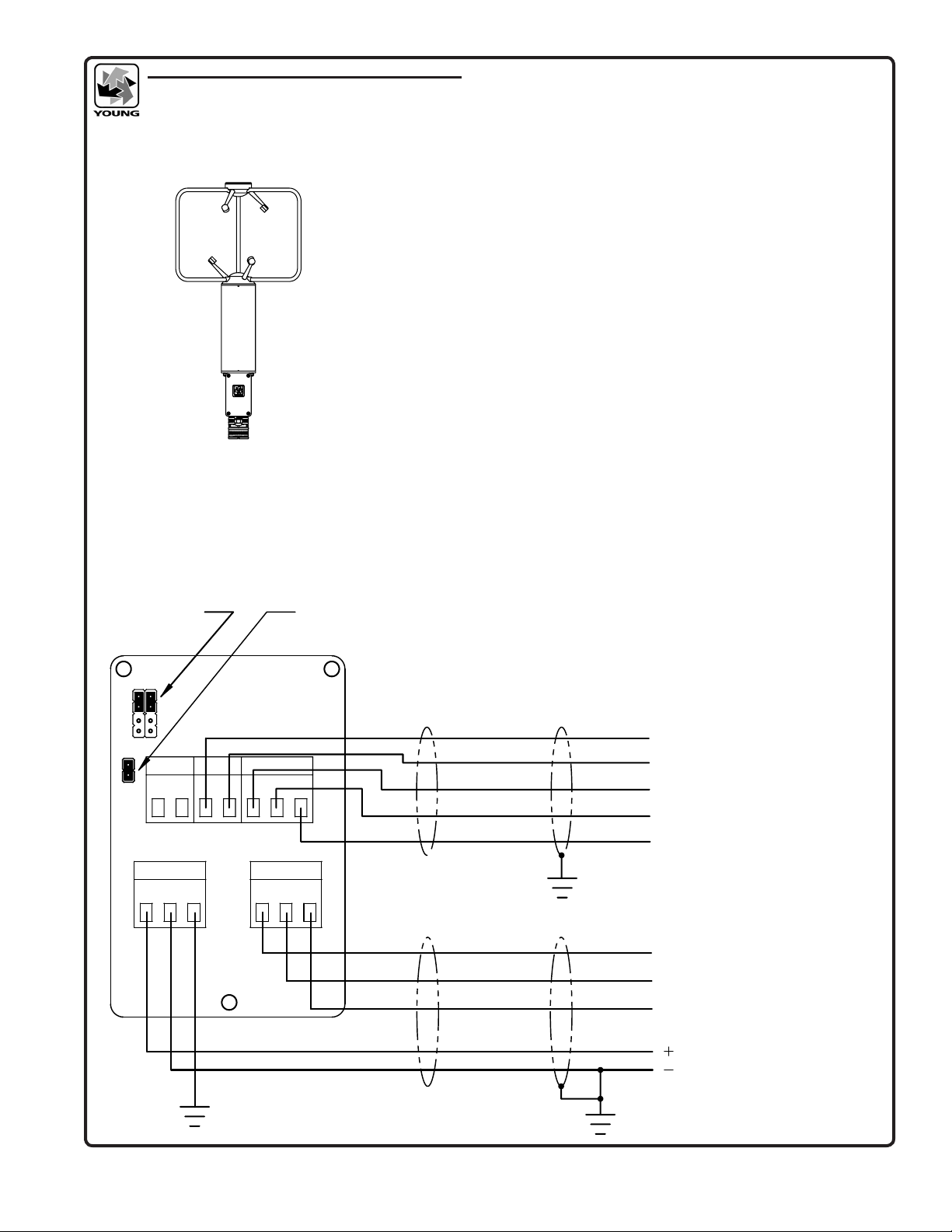

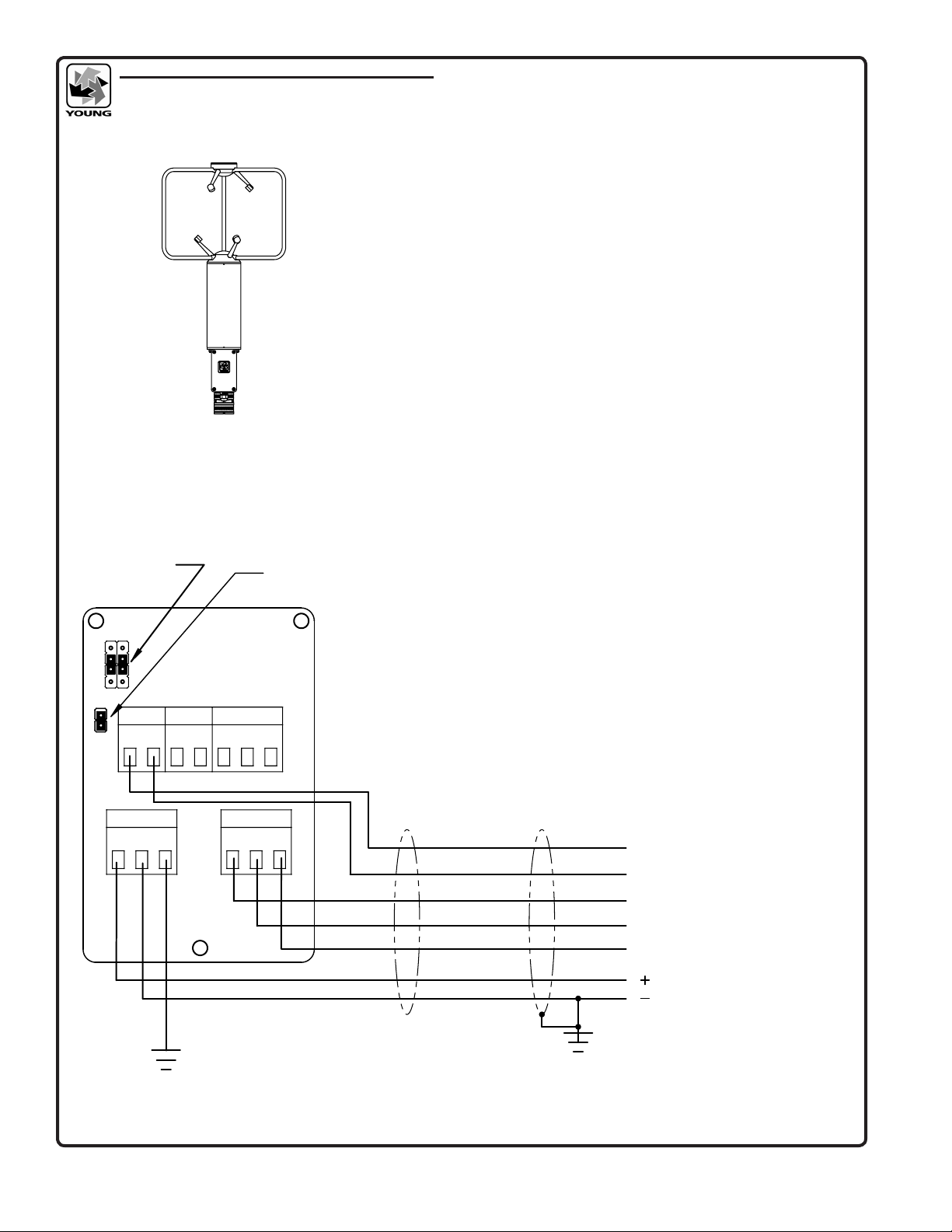

VIN1 to VIN4 are the four voltage input channels. Standard calibration

sets VIN1 and VIN2 to 0-5000 mV full scale, VIN3 and VIN4 to

0-1000 mV full scale. In all cases, the voltage input measurement is

normalized to a 0-4000 unitless scale and this is the value that will

appear in the output string.

UVW is the orthogonal u, v, and w wind velocities. All three values

are output. Typically the 81000V is oriented with u-axis aligned east-

west and v-axis aligned north-south. In this orientation, +u values =

wind from the east; +v values = wind from the north. Wind from below

(updraft) = +w. Refer to Appendix B for illustration.

2D SPEED is wind magnitude in the u-v plane.

3D SPEED is wind magnitude in three dimensional space.

AZIMUTH is the 0.0-359.9° wind direction angle in the u-v plane.

With the 81000V junction box facing south, 0.0° = north, 90.0° = east,

180.0° = south, and 270.0° = west. Refer toAppendix B for illustration.

ELEVATION is the ±90.0° wind elevation angle relative to the u-v

plane. Values are positive when wind is from below (updraft) and

negative when from above (downdraft). Effective elevation angle

measurements are limited to ±60.0°. Refer to Appendix B for

illustration.

SOS is the speed of sound.

Ts is the sonic temperature derived from SOS.

CHKSUM calculates the bitwise exclusive-or of all characters in the

output string starting with the rst character and ending with the last

character of the last eld before the checksum. The checksum is

expressed as a two-digit hex value preceded a space.

ERROR CODE indicates the validity of the measurement. Any

non-zero value indicates an invalid measurement. ERROR

HANDLING must be set to INCLUDE INVALID DATA to use

this eld. Keys to the error codes provide no useful information

to the user.

INTERNAL VOLTAGE is the internal supply voltage. Because

it is measured after current overload protection devices, it

will always be less than the supply voltage measured at the

connection terminals.

NMEA

NMEA sends wind speed and direction in NMEA marine format to

Young Model 06206 Marine Wind Tracker display or other NMEA

device. The sentence is $WIMWV,aaa,R,ss.s,N,A where aaa = wind

direction angle in degrees and ss.s = wind speed in knots. When

NMEA is selected the OUTPUT RATE is changed to 4 Hz and

THRESHOLD is set to 50 cm/sec. Most NMEA systems use 4800

baud but, because some systems use other baud rates, this setting

should be changed manually if necessary.