1 INDEX

1

INDEX ............................................................................................................................................................................................. 2

2

PRODUCT DESCRIPTIONS............................................................................................................................................................. 4

2.1 INTENDED USES /APPLICATIONS .................................................................................................................................................................... 4

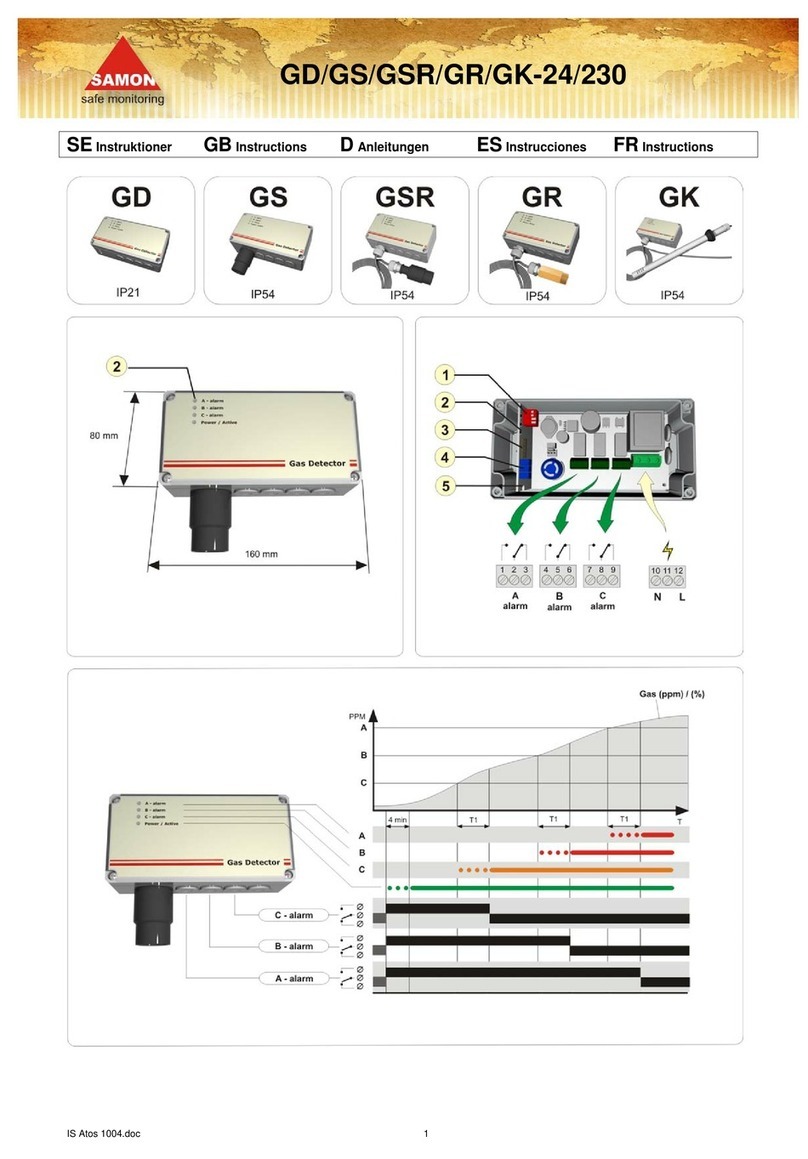

2.2 PHYSICAL DIMENSIONS ................................................................................................................................................................................... 5

3

INSTALLATION............................................................................................................................................................................... 6

3.1 GENERAL INFORMATION................................................................................................................................................................................. 6

3.2 INSTALLATION TIPS .......................................................................................................................................................................................... 6

3.2.1 Equipment rooms........................................................................................................................................................................................................................ 6

3.2.2 Cold rooms .................................................................................................................................................................................................................................. 6

3.2.3 Chillers........................................................................................................................................................................................................................................... 7

3.2.4 Air conditioning - direct VRF/VRV systems........................................................................................................................................................................... 7

3.3 INSTALLATION................................................................................................................................................................................................. 7

Electrical connection ....................................................................................................................................................................................................... 9

3.4 ADDITIONAL INSTALLATION NOTES ................................................................................................................................................................10

4

OPERATION.................................................................................................................................................................................10

4.1 POWER ON ...................................................................................................................................................................................................10

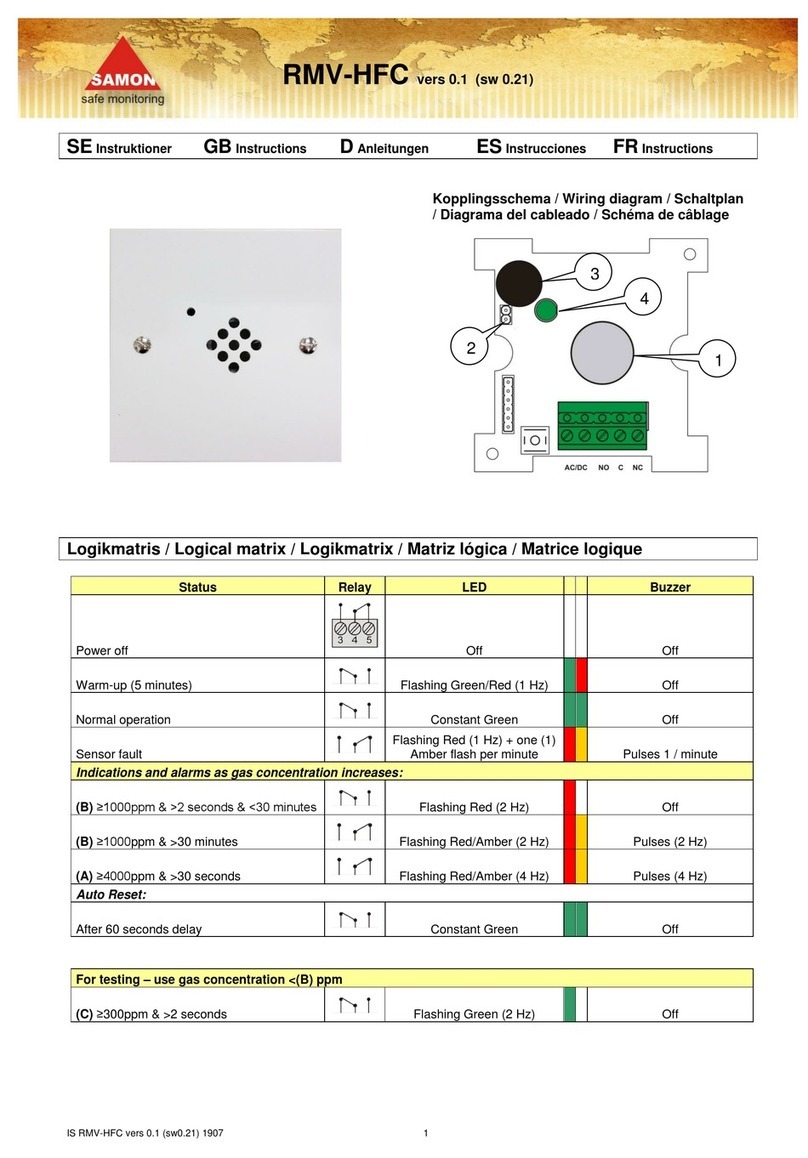

4.2 DEVICE OPERATING STATES............................................................................................................................................................................11

4.3 SETTING THE DEVICE USING THE ROTARY SWITCH .............................................................................................................................................11

Description of the rotary switch LEDs ................................................................................................................................................................................................ 13

Possible configurations ....................................................................................................................................................................................................................... 13

J6 voltage value conversion table / selected function ................................................................................................................................................... 14

4.4 ANALOGUE OUTPUT......................................................................................................................................................................................15

4.5 ALARM MANAGEMENT .................................................................................................................................................................................16

Alarm set points ................................................................................................................................................................................................................................... 16

4.6 MAGNETIC KEY FOR CONFIGURATION ..........................................................................................................................................................17

4.6.1 Bluetooth activation................................................................................................................................................................................................................ 17

4.6.2 Alarm/warning management ............................................................................................................................................................................................. 17

4.7 SAMON GLACIÄRAPP FEATURES ...............................................................................................................................................................18

4.7.1 Connecting the device via Bluetooth ................................................................................................................................................................................. 18

4.8 MODBUS®NETWORK ..................................................................................................................................................................................21

Parameters for RS485 communication selectable via app or rotary switch .................................................................................................................... 21

4.9 TABLE OF MODBUS®VARIABLES .....................................................................................................................................................................22

Function 04 Read Input Registers ...................................................................................................................................................................................................... 22

Function 06 Write Single Register & Function 16 Write Multiple Register .................................................................................................................................. 23

Function 04 Read Input Registers ...................................................................................................................................................................................................... 23

Input register 302 bits......................................................................................................................................................................................................................... 24

Function 05 Write Single Coil & Function 01 Read Coils ............................................................................................................................................... 24

5

MAINTENANCE...........................................................................................................................................................................25

5.1 CALIBRATION PROCEDURE .............................................................................................................................................................................25

5.2 CALIBRATION KIT ...........................................................................................................................................................................................25

5.3 CALIBRATION VIA APP ....................................................................................................................................................................................26

5.4 CALIBRATION VIA MODBUS®COMMUNICATION ..................................................................................................................................................................... 28

5.4.1 Diagram of the calibration procedure............................................................................................................................................................................... 29

5.4.2 Operation of the registers for calibration.......................................................................................................................................................................... 30

5.5 SENSOR REPLACEMENT PROCEDURE .............................................................................................................................................................31

Built-in version...................................................................................................................................................................................................................................... 31

Remote version .............................................................................................................................................................................................................. 31

5.6 CLEANING THE DEVICE ..................................................................................................................................................................................32