– 4 –

A2

A3

EXIT

Never use the combine for anything but threshing.

Manual feeding of crops onto the cutting table is pro-

hibited.

Before starting, particularly reversing, make sure that

everybody nearby is aware of your intentions.

Test the brakes as soon as you start, and stop immedi-

ately if the brakes or steering operate defectively.

Never adjust the seat or steering wheel while driving.

Never leave the cab while the combine is moving.

Never leave the engine running unattended.

Do not open any guards with the engine running.

Do not climb on top of the grain tank or the straw walk-

ers with the engine running, and do not let anybody

else do it either.

Beware of the cutting mechanism and the rotating

chopper knife.

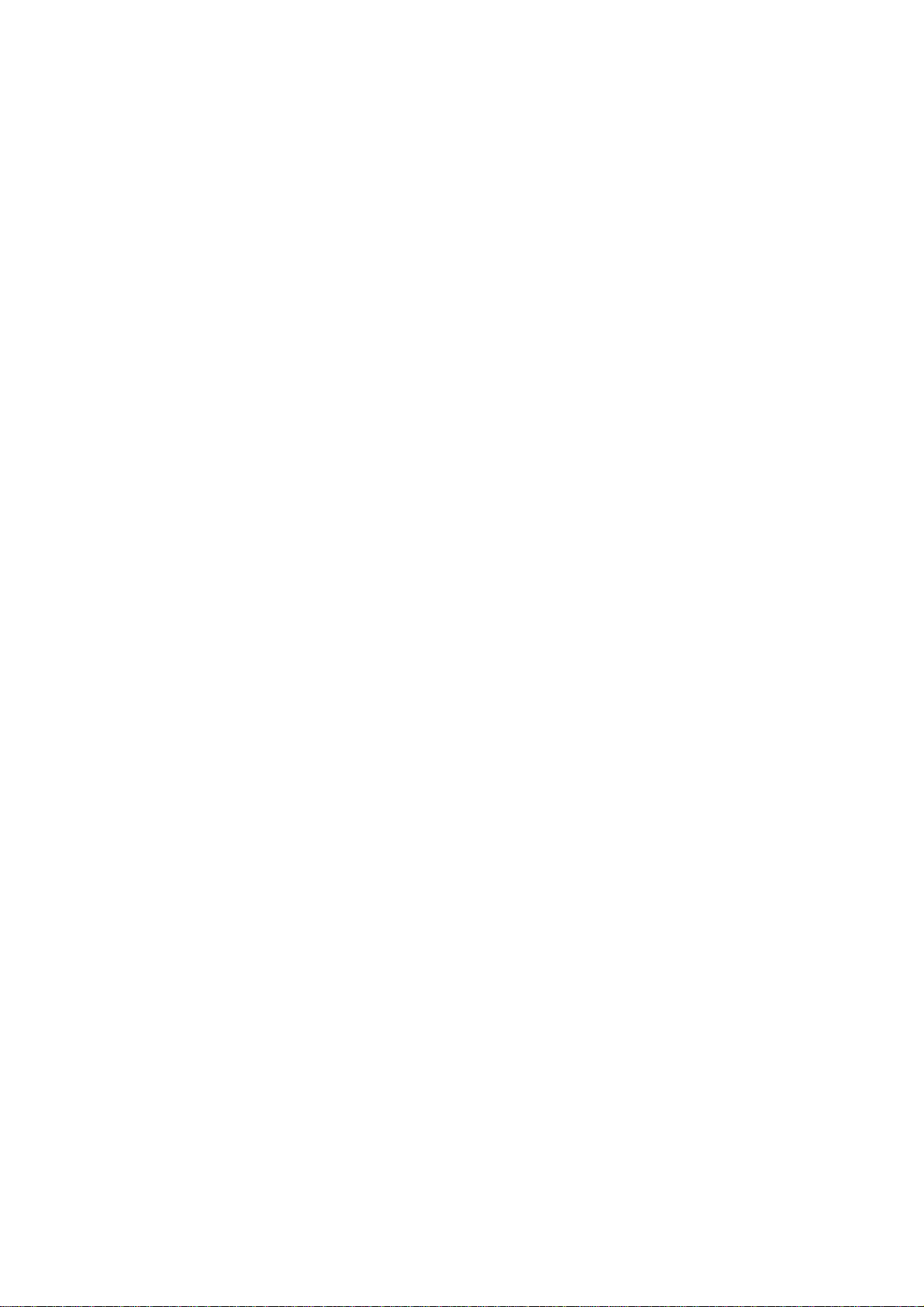

Keep in mind that with the chopper rotating, there is a

20 m no-access danger zone behind the chopper.

Drive carefully on hillsides; the combine may overturn,

particularly with the grain tank full.

The combine cab is no safety cab.

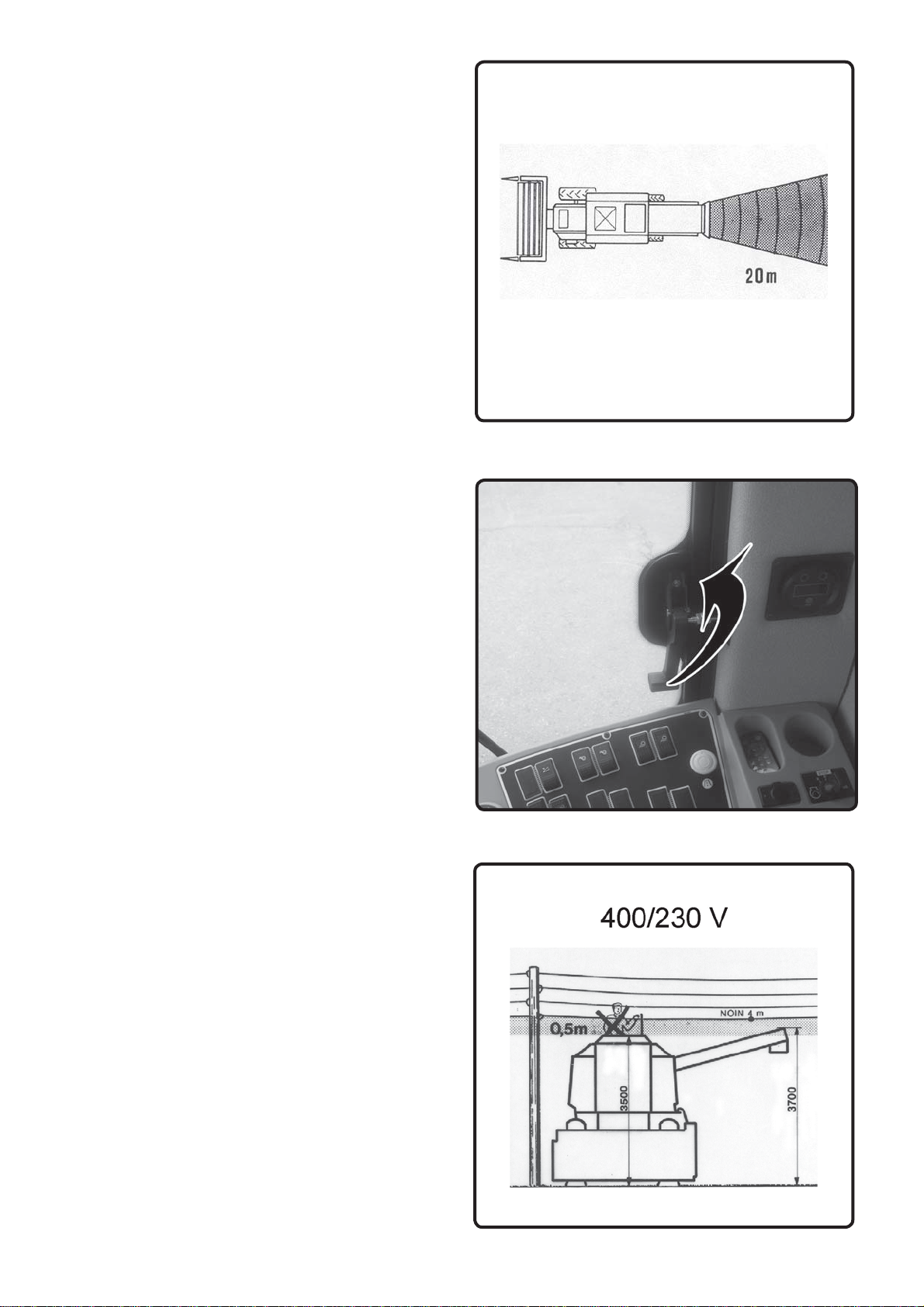

THE RIGHT-HAND SIDE DOOR MAY BE USED AS

AN EMERGENCY EXIT. PULL UP THE HANDLE,

AND OPEN THE WINDOW. Fig. EXIT

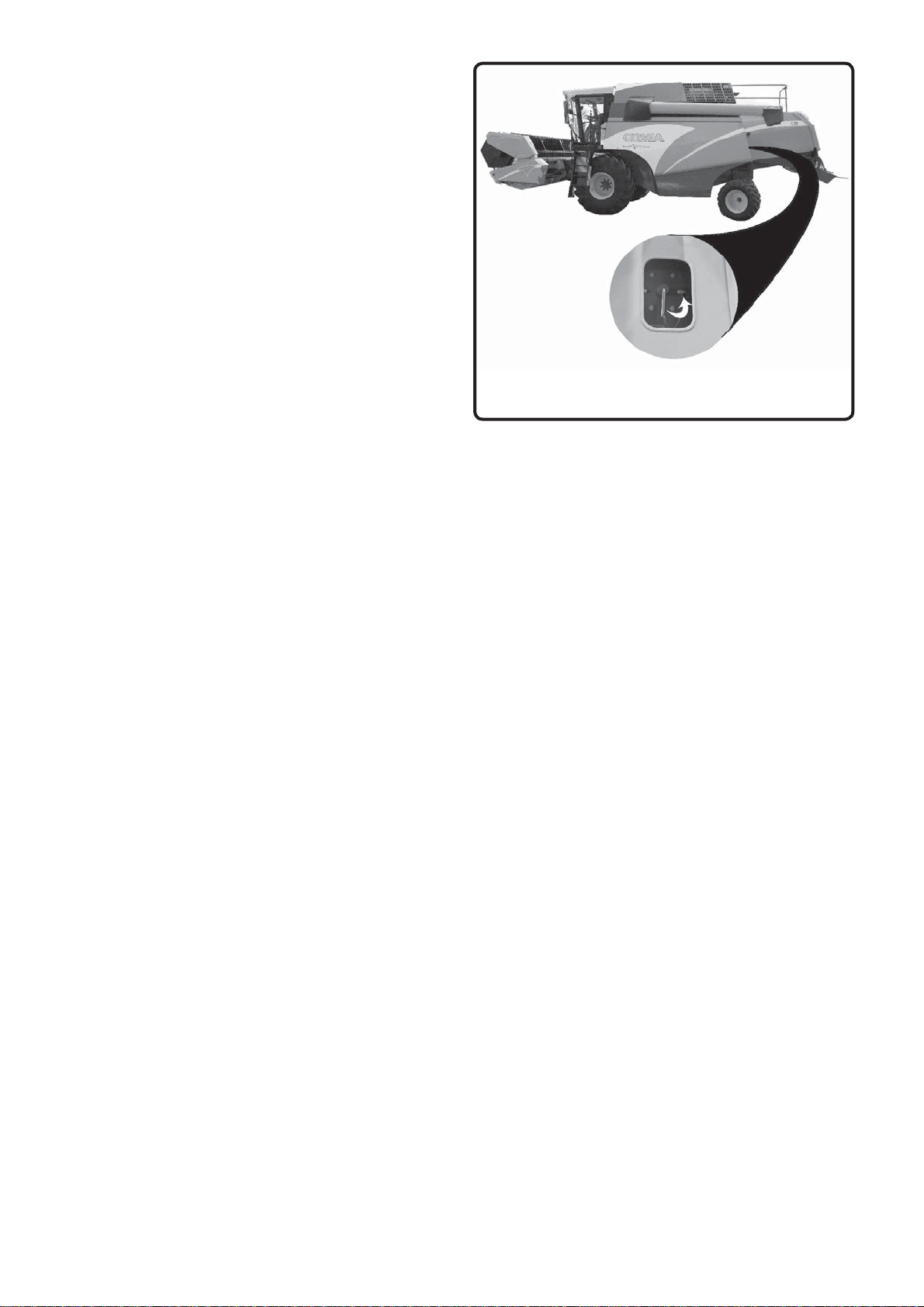

Note the recommended safety distances when thresh-

ing under power lines.

Stop the engine before cleaning or servicing the com-

bine.

Stop the combine and the engine immediately if there

is an alarm or any abnormal sounds or smells. Find out

the reason for them, and solve the problem before car-

rying on with threshing.

Support or lock the cutting table and the reel before

going beneath them.

Never clean the combine without proper equipment.

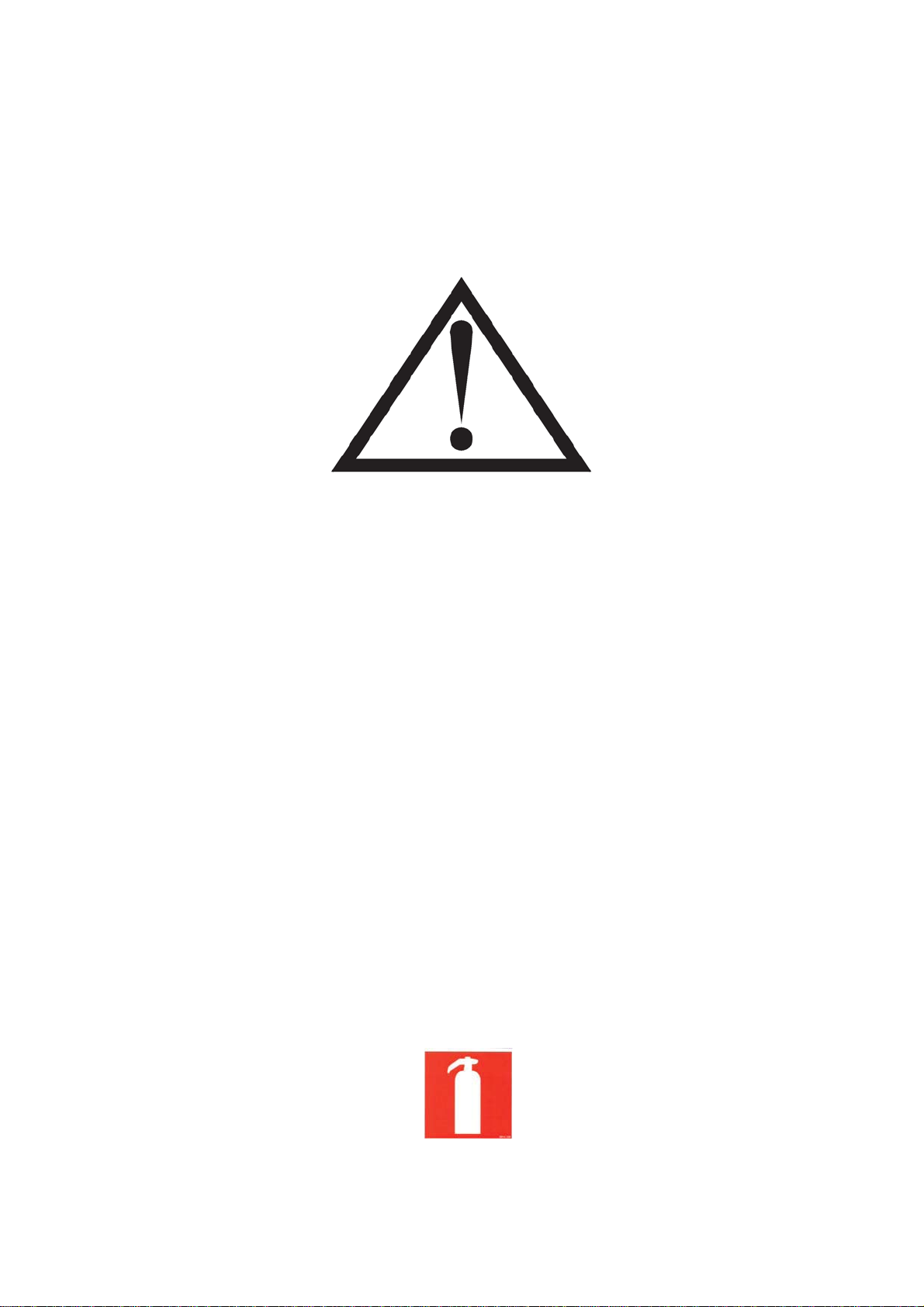

When leaving the combine, lower the cutting table,

lock the parking brake, stop the engine and remove

the ignition key.

SAFETY DISTANCES WHEN THRESHING

UNDER OPEN-WIRE POWER LINES

The minimum clearance between the combine and

power lines with voltage must be in accordance with

the enclosed illustration, in which the danger zone is

darkened.

Low-voltage power lines, ¿g. A3 2404009 can be

distinguished from high-voltage line, ¿g. A4...A5 over

1 k9 by the smaller insulators and the fact that there

are usually 4 low-voltage lines.

In case the height or voltage of the power line is dif-

¿cult to estimate, the Electric Company shall be con-

sulted.