Contents

EB 3969 EN 3

1 Safety instructions and measures ...................................................................5

1.1 Notes on possible severe personal injury .........................................................8

1.2 Notes on possible personal injury ...................................................................8

1.3 Notes on possible property damage................................................................9

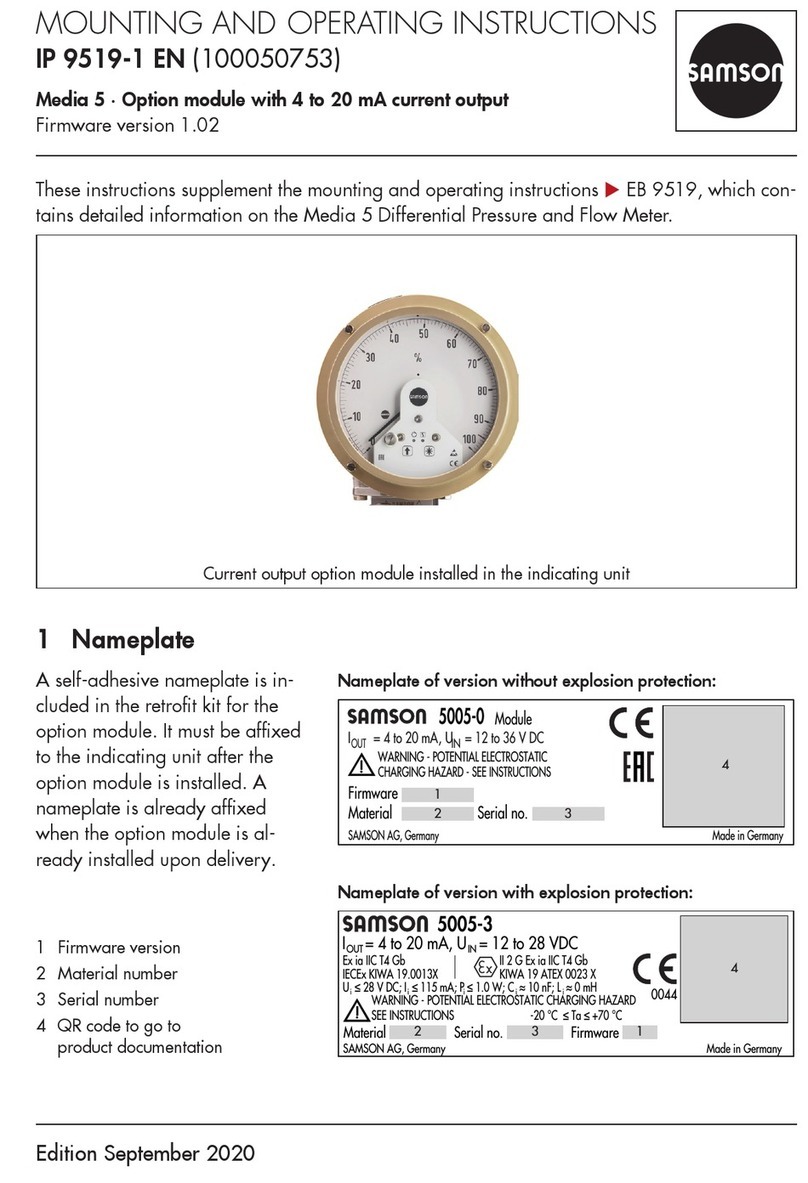

2 Markings on the device ...............................................................................10

2.1 Nameplate..................................................................................................10

2.2 Article code.................................................................................................11

2.3 Summary of explosion protection approvals...................................................13

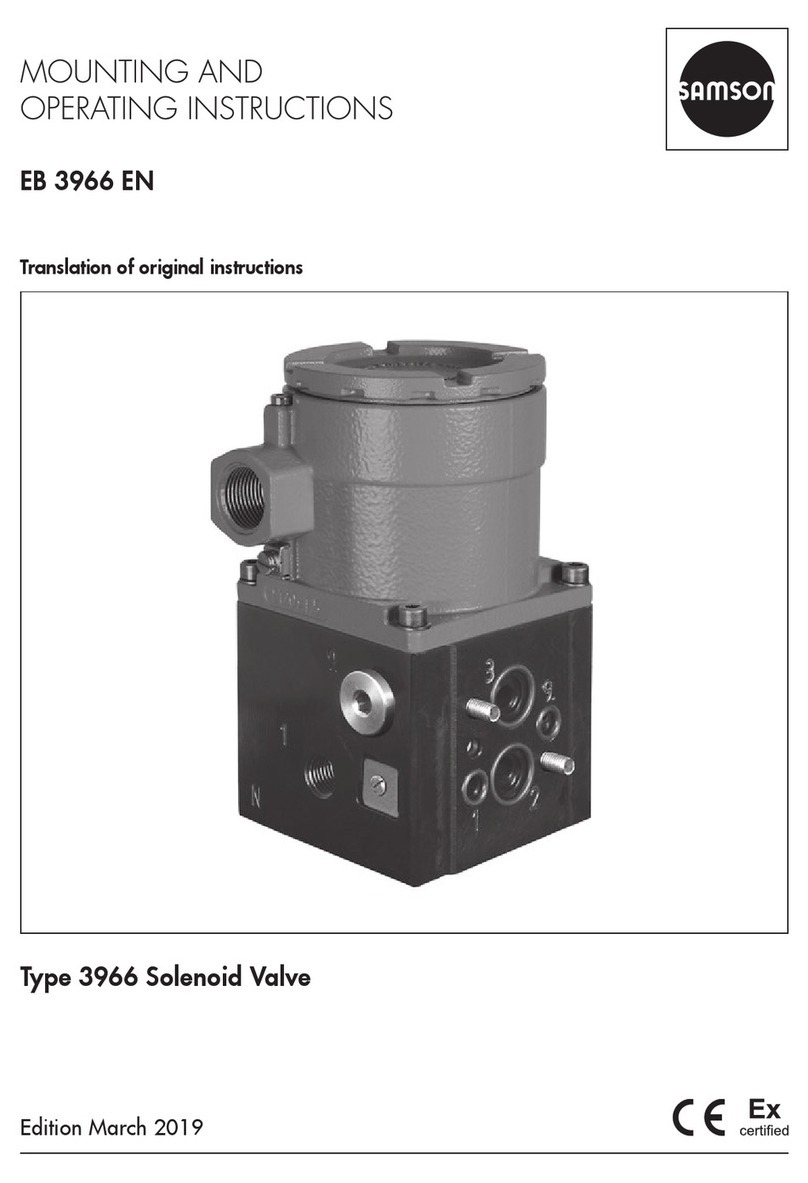

3 Design and principle of operation ................................................................14

3.1 Accessories and spare parts .........................................................................15

3.2 Technical data .............................................................................................18

3.3 Dimensions in mm........................................................................................22

4 Measures for preparation............................................................................27

4.1 Unpacking ..................................................................................................27

4.2 Transporting ................................................................................................27

4.3 Storage.......................................................................................................27

5 Mounting and start-up.................................................................................28

5.1 Installation...................................................................................................28

5.1.1 DirectattachmentaccordingtoVDI/VDE3847 ..............................................29

5.1.2 RotaryactuatorsaccordingtoVDI/VDE3845................................................30

5.1.3 AttachmentaccordingtoIEC60534-6...........................................................31

5.2 Exhaust air feedback for single-acting actuators.............................................32

5.2.1 DirectattachmentaccordingtoVDI/VDE3847 ..............................................32

5.2.2 RotaryactuatorsaccordingtoVDI/VDE3845................................................32

5.2.3 AttachmentaccordingtoIEC60534-6...........................................................32

5.3 Pneumatic connections..................................................................................32

5.3.1 Connecting the supply air.............................................................................32

5.3.2 Port labeling................................................................................................33

5.3.3 Sizing of the connecting line .........................................................................33

5.3.4 Compressed air quality.................................................................................34

5.3.5 Pilot supply..................................................................................................34