Contents

EB 8384-2 EN 3

1 Important safety instructions ..........................................................................8

2 Article code...................................................................................................9

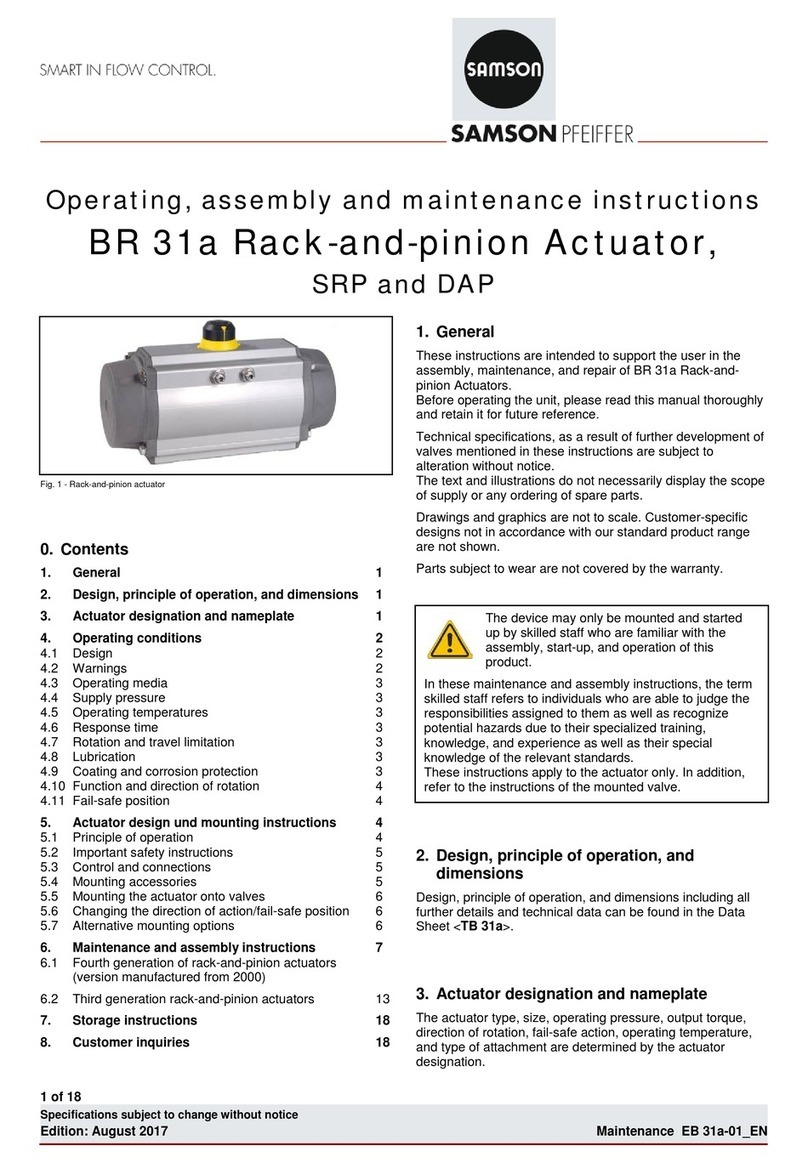

3 Design and principle of operation ................................................................10

3.1 Additional equipment...................................................................................11

3.2 Communication ...........................................................................................12

3.3 Technical data .............................................................................................13

4 Attachment to the control valve – Mounting parts and accessories .................20

4.1 Direct attachment.........................................................................................22

4.1.1 Type3277-5 Actuator ..................................................................................22

4.1.2 Type3277 Actuator .....................................................................................24

4.2 Attachment according to IEC60534-6...........................................................26

4.3 Attachment according to VDI/VDE3847 .......................................................28

4.4 Attachment to Type3510 Micro-ow Valve ....................................................34

4.5 Attachment to rotary actuators ......................................................................34

4.5.1 Heavy-duty version ......................................................................................36

4.6 Reversing amplier for double-acting actuators ..............................................38

4.6.1 Reversing amplier (1079-1118 or 1079-1119)............................................40

4.7 Attachment of external position sensor...........................................................42

4.7.1 Mounting the position sensor with direct attachment........................................43

4.7.2 Mounting the position sensor with attachment according to IEC60534-6 .........45

4.7.3 Mounting the position sensor to Type3510 Micro-ow Valve...........................46

4.7.4 Mounting on rotary actuators........................................................................47

4.8 Mounting the leakage sensor ........................................................................48

4.9 Attaching positioners with stainless steel housings...........................................49

4.10 Air purging function for single-acting actuators ..............................................49

4.11 Required mounting parts and accessories.......................................................50

5 Connections ................................................................................................55

5.1 Pneumatic connections..................................................................................55

5.1.1 Signal pressure gauges ................................................................................55

5.1.2 Supply pressure ...........................................................................................55

5.1.3 Signal pressure (output)................................................................................56

5.2 Electrical connections ...................................................................................56

5.2.1 Switching amplier ......................................................................................59